Method and system for detecting dynamic lift range of gag bit of common-rail oil injector

A common rail injector and detection method technology, applied in the field of measurement and control, can solve the problems of low control accuracy, slow response speed, and small control degree of freedom, and achieve high detection accuracy, increased accuracy, and high repeatable measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

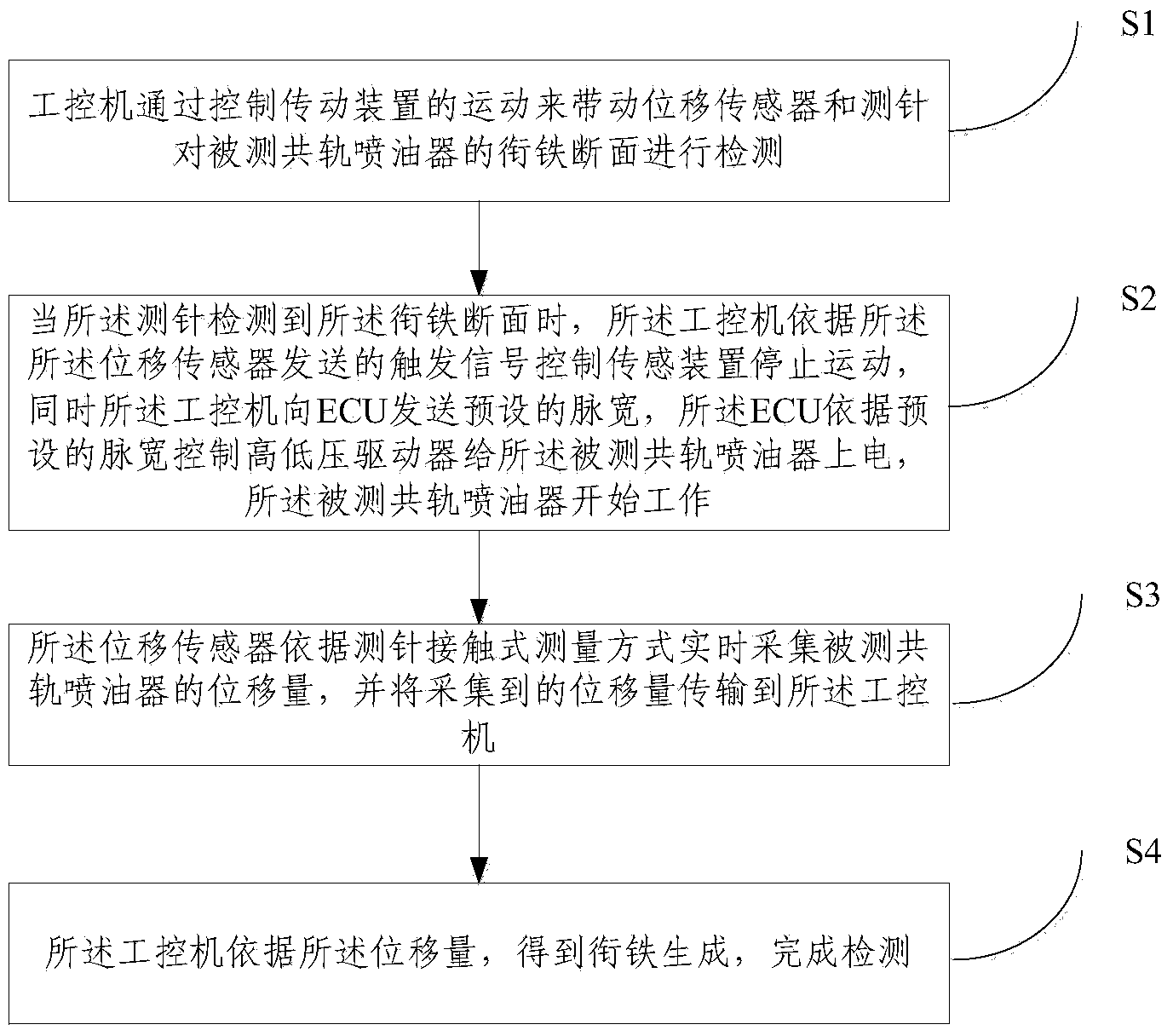

[0033] Such as figure 1 As shown, the embodiment of the present invention provides a method for detecting the dynamic lift of the common rail injector armature, including:

[0034] S1. The industrial computer drives the displacement sensor and the tester to detect the end face of the armature of the common rail injector under test by controlling the movement of the transmission device;

[0035] S2. When the stylus detects the end face of the armature, the industrial computer controls the sensing device to stop moving according to the trigger signal sent by the displacement sensor, and at the same time, the industrial computer sends a preset pulse width to the ECU , the ECU controls the high and low voltage drivers to power on the tested common rail injector according to the preset pulse width, and the tested common rail injector starts to work;

[0036] S3. The displacement sensor collects the displacement of the common rail injector under test in real time according to the s...

Embodiment 2

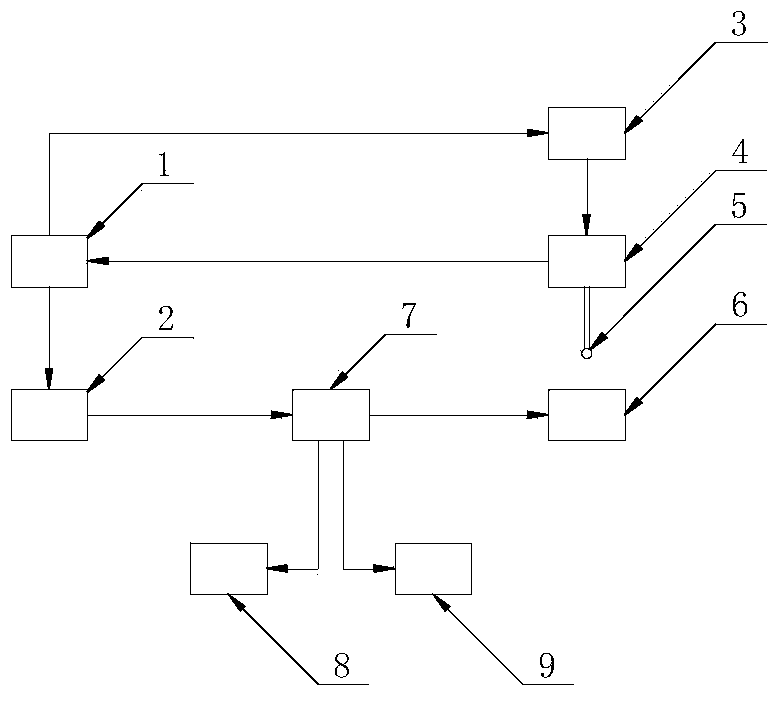

[0047] Such as figure 2 As shown, the embodiment of the present invention also provides a common rail injector armature dynamic lift detection system, including: industrial computer, transmission device, displacement detection device, ECU, high and low voltage driver,

[0048] The displacement detection device includes a displacement sensor and a stylus;

[0049] The high and low pressure drivers are respectively connected with the ECU and the tested common rail injector.

[0050] The industrial computer is respectively connected with the transmission device, the displacement detection device and the ECU, the transmission device is connected with the displacement detection device, and the displacement detection device detects the common rail injector under test.

[0051] Preferably, the device further includes a voltage regulator connected to the high and low voltage drivers for adjusting the driving voltage of the tested common rail injector so as to adapt to common rail in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com