Solid preparation swelling pressure determination device and method

A technology for solid preparations and measuring devices, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of irregular shape, undetectable, small size, etc., and achieve easy operation, high sensitivity, and good scientific research. and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

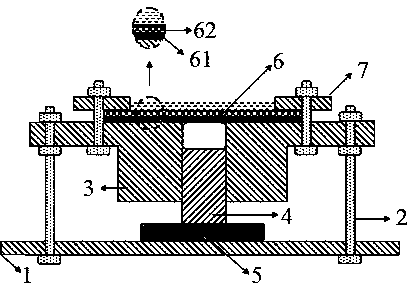

[0036] Embodiment 1: Constant volume expansion pressure measuring device

[0037] Such as figure 1 The shown constant volume expansion pressure measurement device includes a fixed seat 1, a height adjustment structure 2, a mold 3, a probe 4 used in conjunction with the mold 3, and a pressure sensor 5. The height adjustment structure 2 is composed of a screw and a nut, and the mold 3 passes through The cooperation between the screw and the nut is fixed with the fixed seat 1, the pressure sensor 5 is fixed with the fixed seat 1, and the top of the mold 3 is also equipped with a water-permeable structure 6, which is composed of a water-permeable membrane 61 and a water-permeable gasket 62, and the water-permeable structure 6 passes through the lock. The tightening structure 7 is fixed with the mold 3, wherein the locking structure 7 is composed of a screw rod, a nut and a pressing block.

[0038] In this embodiment, the diameter of the probe 4 is 5-12mm, the inner diameter of...

Embodiment 2

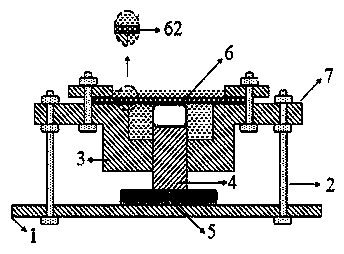

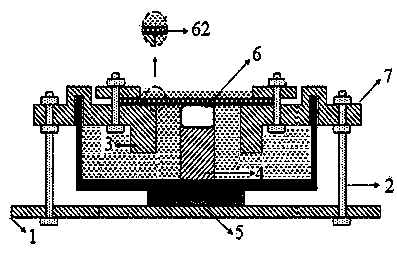

[0040] Example 2: Height-fixed expansion pressure measuring device

[0041] Such as diagram 2-1 The height-fixed type measuring device for membrane-controlled sample expansion pressure includes a fixed seat 1, a height adjustment structure 2, a mold 3, a probe 4 matching the inner diameter of the mold 3, and a pressure sensor 5. The height adjustment structure 2 is composed of a screw and a nut, the mold 3 is fixed to the fixed seat 1 through the cooperation of the screw and the nut, the pressure sensor 5 is fixed to the fixed seat 1, and a permeable structure 6 is installed on the top of the mold 3, and the permeable structure 6 is composed of a permeable gasket 62. The permeable structure 6 is fixed to the mold 3 through the locking structure 7, wherein the locking structure 7 is composed of a screw, a nut and a pressing block, and the fixing seat 1, the height adjustment structure 2, the mold 3, the probe 4 and the locking structure 7 are all made of stainless steel Made...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com