Servo position control method applied to engraving and milling machine

A control method and engraving and milling machine technology, applied in the field of servo control, can solve problems such as large position errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

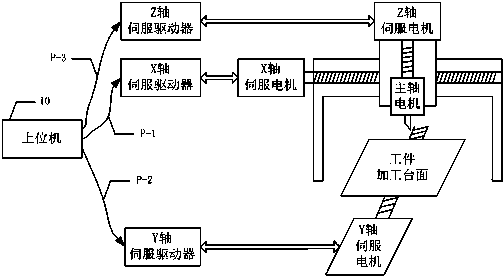

[0025] figure 1 It is a schematic diagram of the structure of the engraving and milling machine. The upper computer 10 outputs three position signals P-1, P-2 and P-3, which are respectively sent to the X-axis, Y-axis and Z-axis servo drivers in the form of pulses, and the X-axis and Y-axis and Z-axis servo drivers drive X-axis, Y-axis and Z-axis servo motors respectively. The Y-axis servo motor drives the workpiece processing table to move in the Y-axis direction; the Z-axis servo motor drives the spindle motor to move in the Z-axis direction, and the spindle motor drives the tool to rotate at high speed, responsible for engraving and milling the workpiece; the Z-axis servo motor and the spindle motor are integrated Driven by the X-axis servo motor, it moves in the X-axis direction.

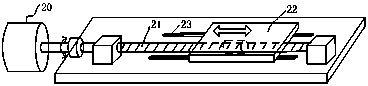

[0026] figure 2 It is a schematic diagram of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com