High-frequency electrodeless lamp

An electrodeless lamp, high-frequency technology, applied to the parts of gas discharge lamps, etc., can solve the problems of unable to meet normal lighting, short service life of filament, poor heat dissipation effect, etc., to prolong service life, good heat dissipation performance, and not easy to damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

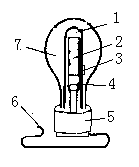

[0008] The structure of the high-frequency electrodeless lamp of the present invention is as figure 1 As shown, a light bulb 7 is installed on the top of the main amalgam 5, and a central cavity 1 is arranged inside the light bulb 7. A power regulator 4 is installed on the main amalgam 5 inside the central cavity 1, and a power coupler 2 is installed on the top of the power regulator 4, and the power coupling An amalgam 5 is installed on one side of the device 2, a high-frequency feeder 6 is provided at the lower part of the main amalgam 5, and fluorescent powder is coated on the inner wall of the central cavity 1 and the bulb 7. The power coupler and power blender are installed in the center cavity inside the bulb. This structure makes the filament not easy to damage, and the lampshade is coated with phosphor powder, which has good heat dissipation performance, prolongs the service life of the filament, and meets the needs of normal lighting. And it can adapt to wide voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com