Organic el sealing device

A sealing device, an organic technology, applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the obstacles of organic EL panels, cannot efficiently manufacture organic EL panels, and cannot maintain the sealing state of high-precision sealing substrates And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0097]

[0098] In the above configuration, the bonding of the sealing substrate 17 to the transfer roller 52 is performed by a person, but it may be performed automatically. In this case, the sealing substrate 17 supply means ( not shown). In addition, although the supply member is demonstrated below, a component element is not shown in figure.

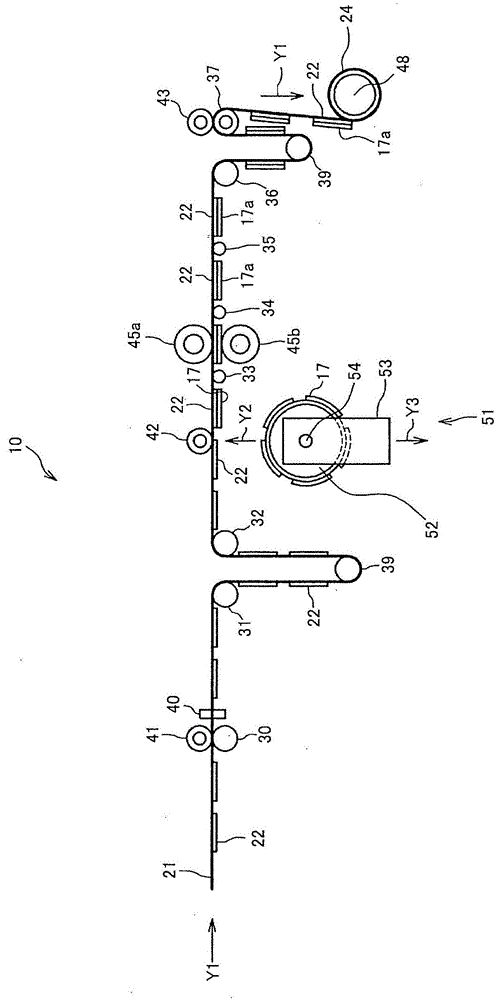

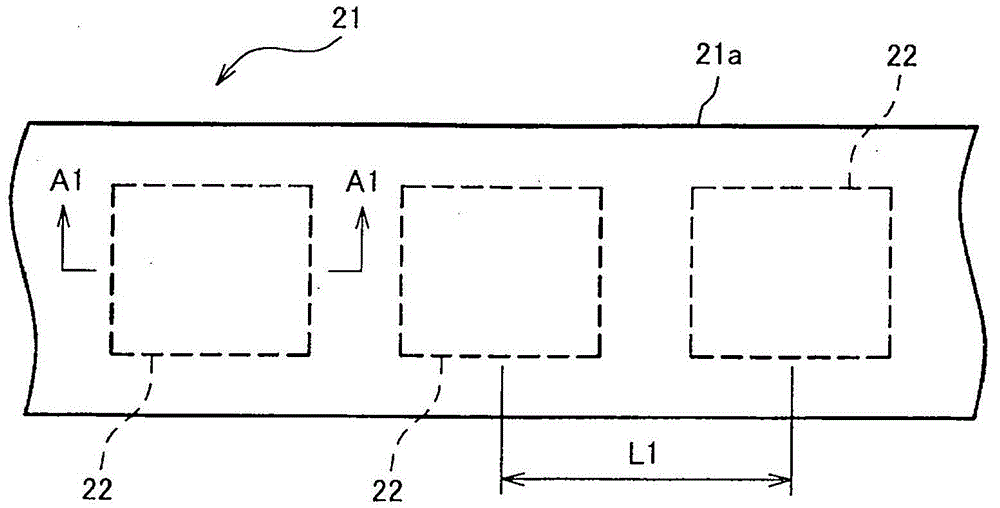

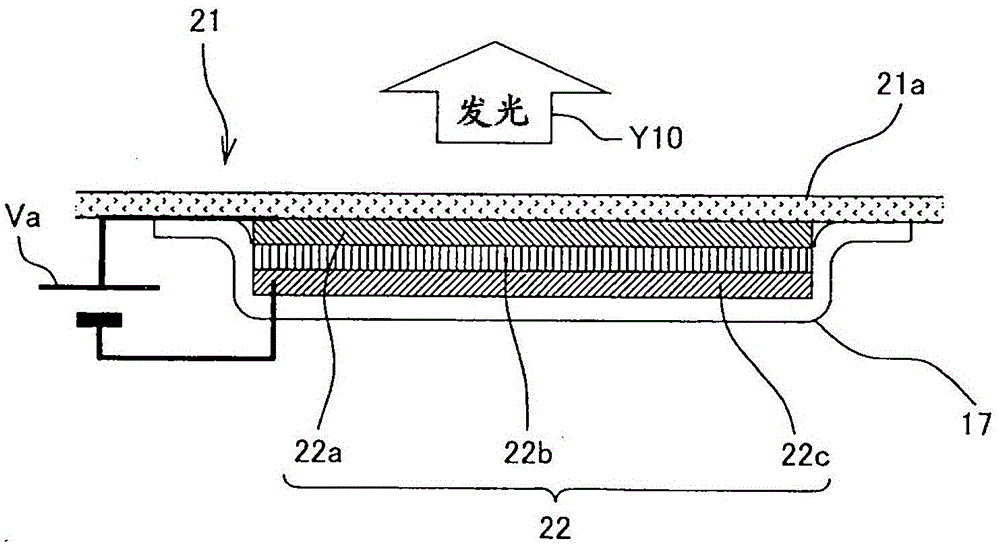

[0099] The supply member has a first member, and the first member is conveyed on the elongated film in a roll-to-roll manner by a plurality of rollers at the interval L1 ( Figure 2A ) and a roll film formed by bonding the sealing substrate 17 with an adhesive force F3 weaker than the adhesive force F2. Furthermore, there is a second member that conveys the sealing substrate 17 on the roll film conveyed by the first member synchronously with the rotation of the transfer roller 52 and makes it abut against the transfer roller 52 and sticks it. The sealing substrate 17 is transferred from the roll film to the transfer roller 52 wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com