A method of manufacturing a joint

A manufacturing method and technology of copper joints, applied in the field of pipe fittings processing, can solve problems such as increasing the difficulty of processing metal joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

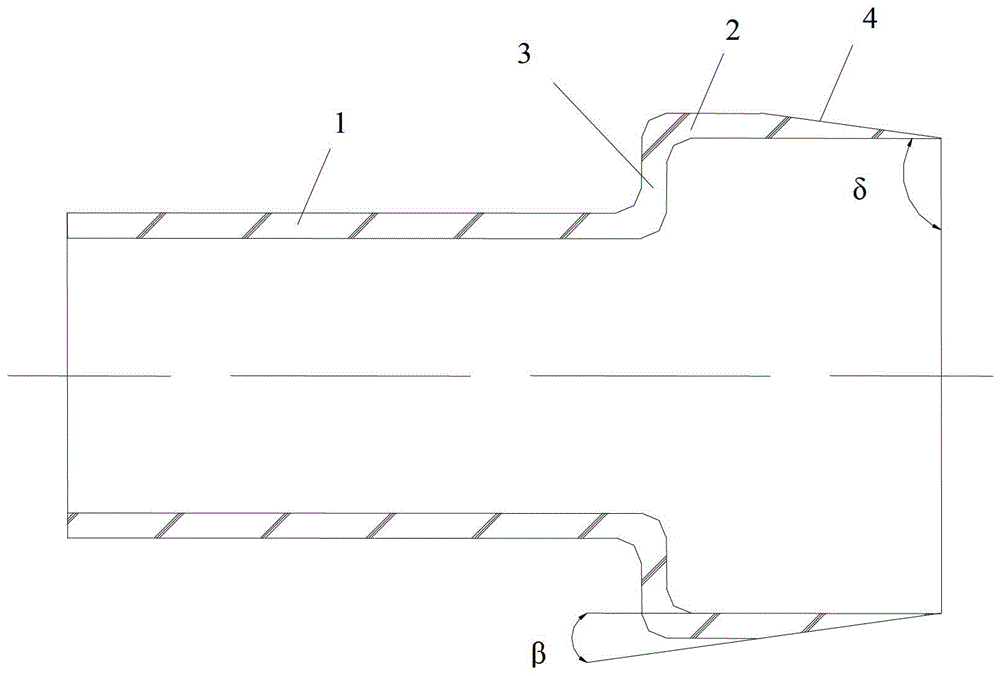

[0021] Below by specific embodiment and in conjunction with accompanying drawing, the present invention is described in detail:

[0022] In this specific embodiment, a copper tube is selected as the raw material.

[0023] See eg figure 1 Shown, a kind of manufacturing method of copper connector, comprises the following steps:

[0024] (1) Material selection: Select copper tubes that meet the requirements according to the drawings;

[0025] (2) Material preparation: sawing the copper tube into small tube blanks according to the drawing size;

[0026] (3) Deburring: remove all burrs on the section of the tube blank;

[0027] (4) Diameter reduction: The tube blank is clamped on the instrument car, and one end of the tube blank is subjected to diameter reduction treatment, and processed into workpieces with different pipe diameters that meet the requirements of the drawings. The workpieces after diameter reduction treatment include pipe diameters smaller than The first pipe se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com