A kind of processing method of decorative board

A processing method and decorative board technology, which is applied in the field of decorative board processing, can solve problems affecting the overall consistency of the appearance, and achieve the effect of no defects in the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a decorative panel, which can be used as an exterior decorative part or decorative panel on electrical equipment such as speakers, refrigerators, washing machines, air conditioners, computers, and monitors. The decorative plate can be an aluminum profile. The aluminum profile has the characteristics of good ductility, easy machining and oxidation coloring, and can meet the use requirements of appearance parts in electrical equipment.

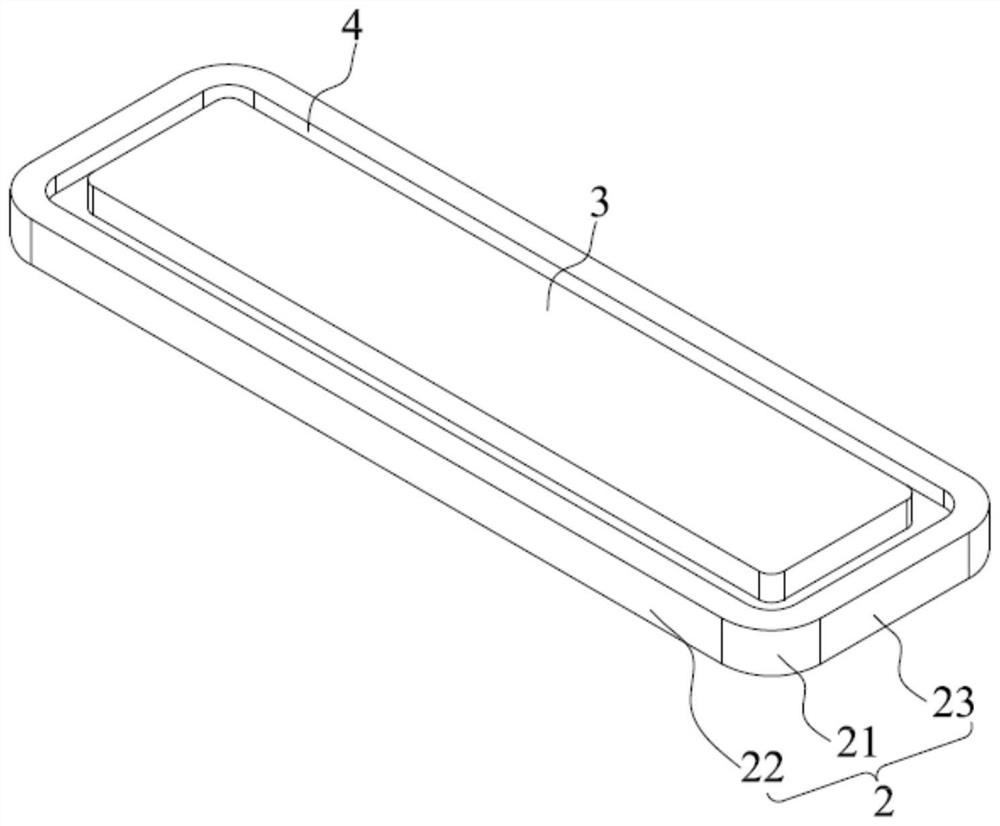

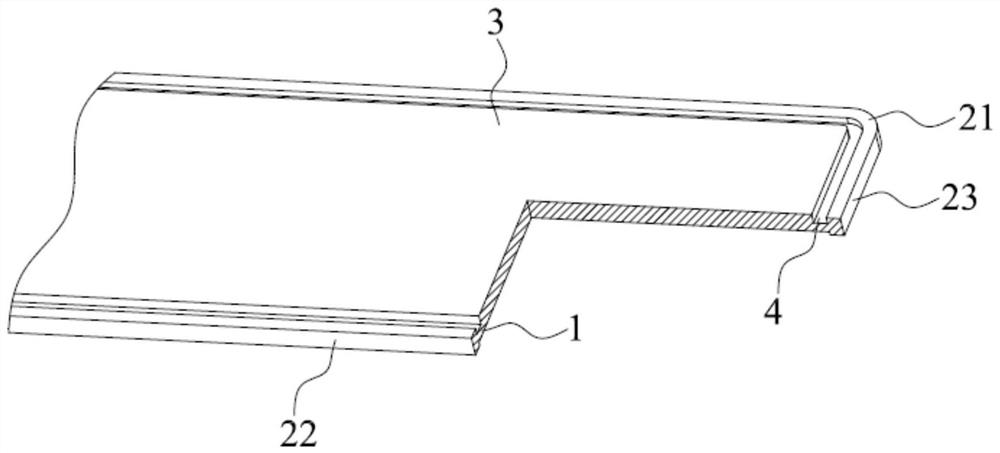

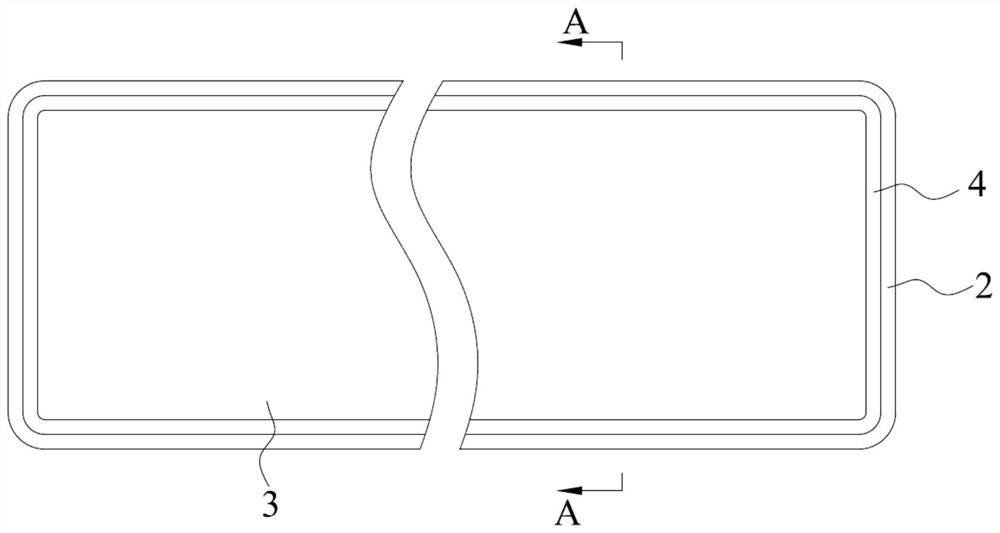

[0049] Such as figure 1 and figure 2 As shown, the decorative board includes a board body 1 and a side edge 2 arranged along the edge of the board body 1 . In this embodiment, the plate body 1 is rectangular, and the four sides of the plate body 1 are provided with side edges 2, and the side edges 2 include a first side edge 22 and a second side edge 23, and the first side edge 22 and the second side edge The corners of 23 are transitionally connected by rounded corners 21 . The middle part of the front of the...

Embodiment 2

[0072] This embodiment provides a decorative board and a processing method for the decorative board. Wherein, the structure of the decorative plate is the same as that in Embodiment 1. The processing method of the decorative plate is roughly the same as that in Embodiment 1, and the difference from Embodiment 1 is the method of sealing the end surface of the second groove 11 .

[0073] Such as Figure 15 and 16 As shown, after processing to form the prefabricated slab, the end of the prefabricated slab is bent downward to form a hem 9 by punching the end of the prefabricated slab. then press Figure 17 As shown in the cutting line, part of the structure of the folded edge 9 is removed by machining, so that the back of the plate body 1 is formed as Figure 18 The rib 13 that closes off the end of the second groove 11 is shown.

[0074] After the end of the second groove 11 is blocked, the second side 23 and the fillet 21 are formed by extrusion process. The specific steps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com