Preparation method of B12 (C, Si, B) 3-SiC two-phase ceramic

A ceramic, 3-sic technology, applied in the field of preparation of B123-SiC two-phase ceramics, can solve the problems of organic matter, unfavorable industrial production, complex preparation process, etc., achieve good dimensional stability, avoid high temperature liquid phase silicon penetration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

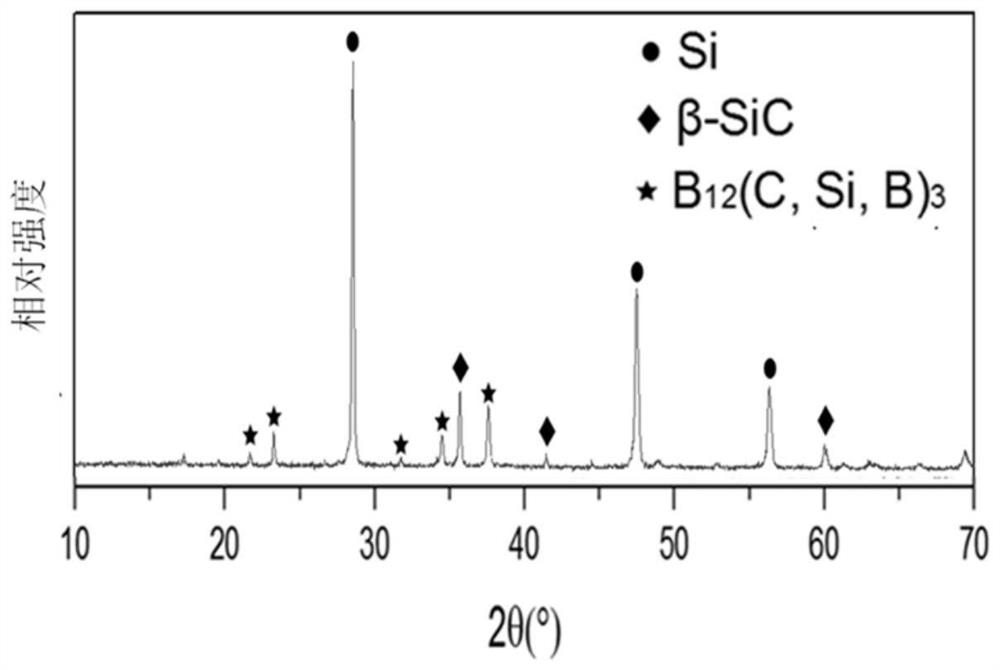

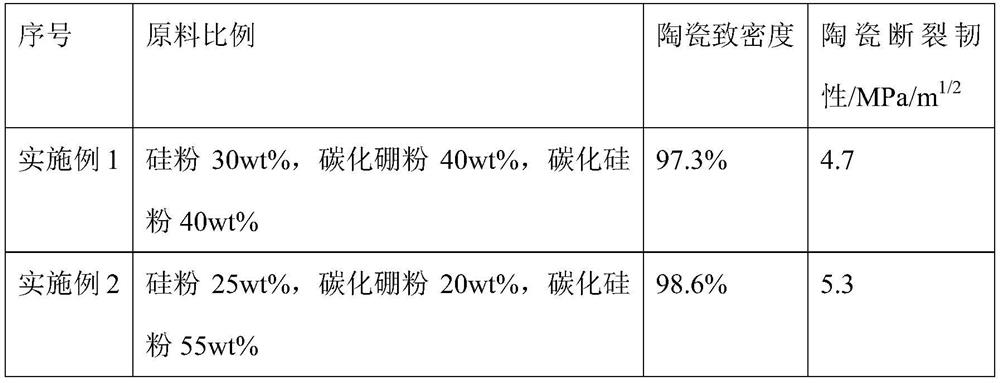

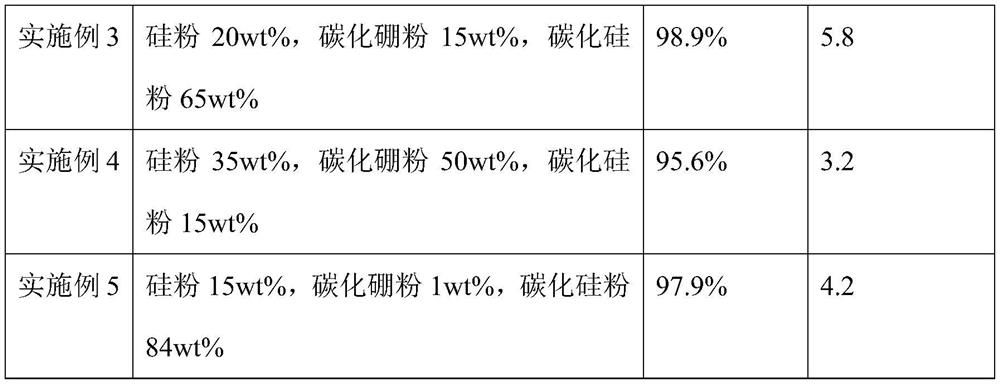

Embodiment 1

[0026] Mix 30g of silicon powder with a particle size of 2μm, 40g of boron carbide powder with a particle size of 20μm, and 40g of silicon carbide with a particle size of 1μm to obtain a mixed powder. The mixed powder is dry-pressed in a one-way hydraulic press, and the pressure is 80MPa. The time is 90s, and the porosity of the green body is 65%; set up a chemical furnace, including Ti+C powder with a mass fraction of 80% (Ti, C molar ratio 1:1) and 20% Al+Fe 2 o 3 Powder (Al, Fe 2 o 3 molar ratio 1:1) composition; the green body is combusted and synthesized in a chemical furnace under vacuum conditions to induce the green body to react to obtain B 12 (C,Si,B) 3 -SiC two-phase ceramic ceramics; found by XRD, the synthesis product is a typical B 12 (C, Si, B) 3 -SiC two-phase ceramics, the density of the product is 97.3%, and the fracture toughness is 4.7MPa / m 1 / 2 .

Embodiment 2

[0028] As in Example 1, other reaction conditions are the same, using 25g of silicon powder with a particle size of 1μm, 20g of boron carbide powder with a particle size of 15μm, and 55g of silicon carbide with a particle size of 0.1μm; using a dry pressing molding pressure of 50Mpa to obtain a green body The porosity is 63%; the chemical furnace is set to burn the synthesis reaction under vacuum conditions to obtain B 12 (C,Si,B) 3 -SiC two-phase ceramics, the density of the product is 98.6%, and the fracture toughness is 5.3MPa / m 1 / 2 .

Embodiment 3

[0030] As in Example 1, the other reaction conditions are the same, using 20g of silicon powder with a particle size of 1 μm, 15g of boron carbide powder with a particle size of 15μm, and 65g of silicon carbide with a particle size of 0.5μm; using a dry pressing molding pressure of 60Mpa to obtain a green body The porosity is 50%; the chemical furnace is set to burn the synthesis reaction under vacuum conditions to obtain B 12 (C,Si,B) 3 -SiC two-phase ceramics, the density of the product is 98.9%, and the fracture toughness is 5.8MPa / m 1 / 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com