a food processor

A technology for food processing machines and machine bases, which is used in household appliances, applications, kitchen appliances, etc., can solve the problems of poor crushing fineness and taste, easy resonance of soymilk machines, and difficulty in one-time deployment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

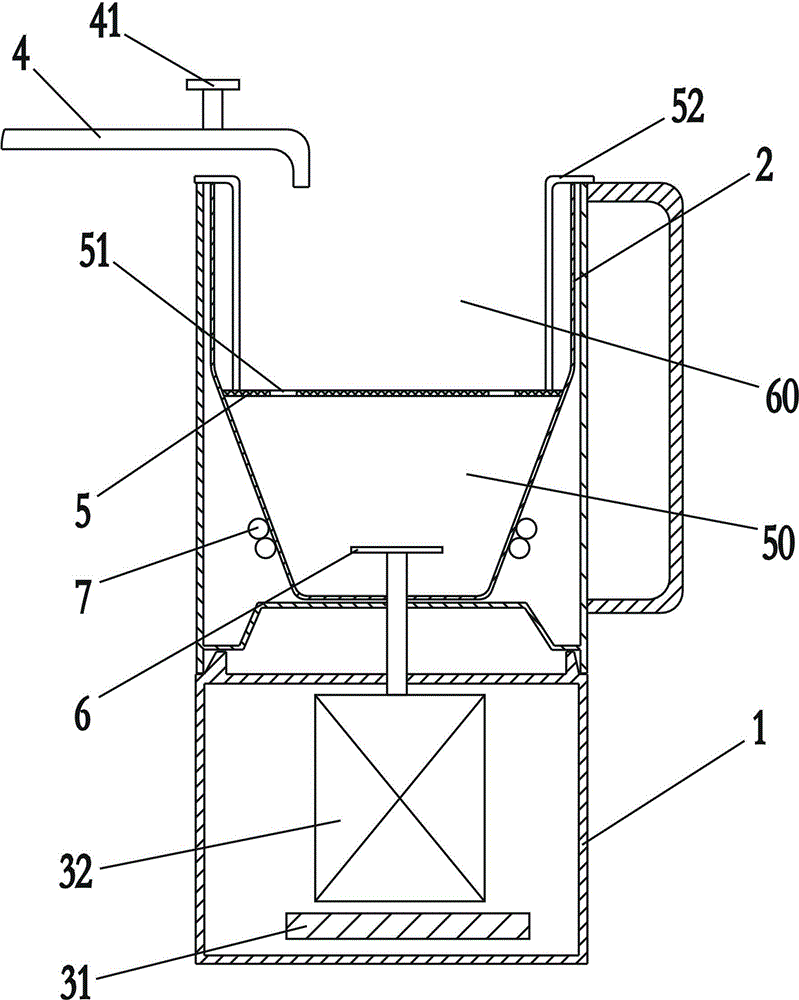

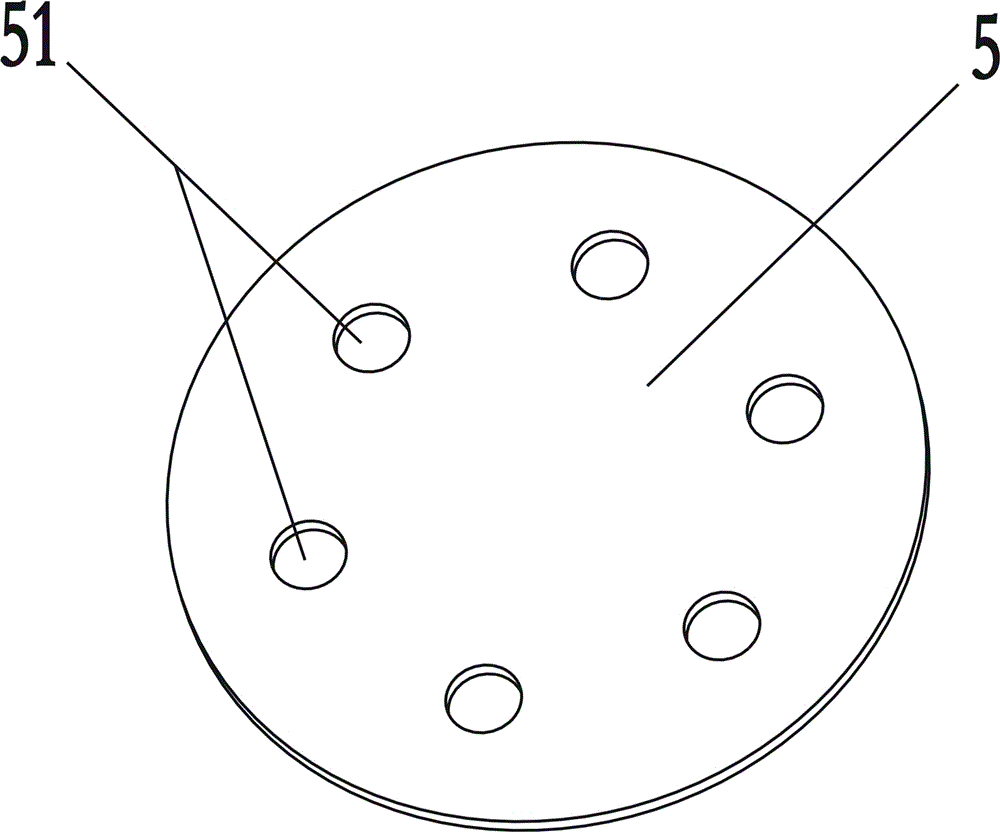

[0027] Such as figure 1 , figure 2 Shown is the first embodiment of the present invention. A food processing machine includes a base 1 and a cup body 2 arranged above the base 1. The base 1 is provided with a control board 31 and a motor 32 electrically connected to the control board 31. The food processing machine also It includes a water supply system 4, the water supply system 4 can supply water to the cup body 2, the cup body 2 is provided with a closing member 5, the closing member 5 and the inner wall of the cup to form a crushing space 50, and by the motor 32 The driven pulverizing device 6 passes through the bottom of the cup and is arranged in the pulverizing space 50. The enclosing member 5 is provided with a communication channel 51 that connects the pulverizing space 50 and the external space 60, and the liquid level is at Enclosing parts 5 or less.

[0028] In this embodiment, the communicating channel 51 is a communicating hole, the lower part of the cup body 2 is...

Embodiment 2

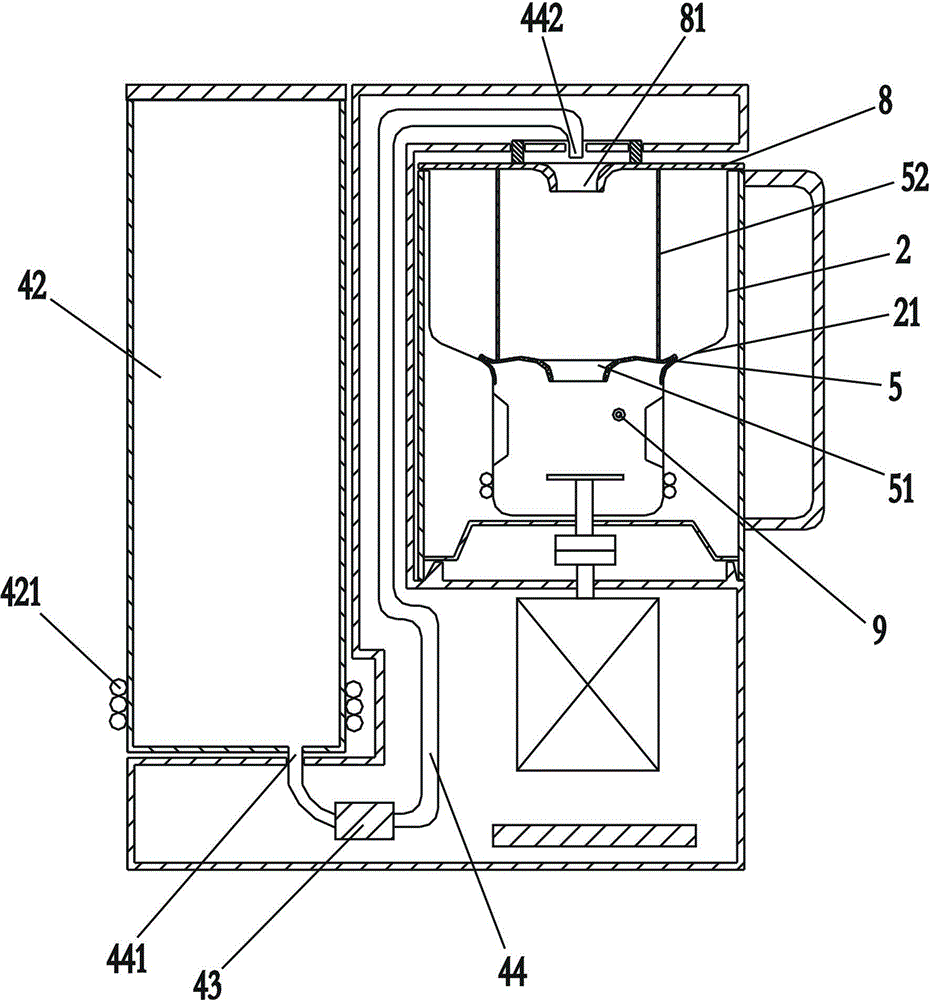

[0038] Such as image 3 , Figure 4 Shown is the second embodiment of the present invention. The difference from the first embodiment is that: in this embodiment, the lower part of the inner wall of the cup body 2 is provided with a step 21 protruding toward the center of the cup body, and the lower part of the cup body is in a contraction shape, and the enclosing member 5 is tightly attached to the step 21. In addition, The food processing machine further includes a cup cover 8 which is covered above the cup body 2, and a connecting member 52 connected to the cup cover 8 is provided on the surrounding part 5. At the same time, the communication channel 51 is provided in the central area 54 of the enclosing member 5 (such as Figure 4 As shown, within the dashed line). And the inner wall of the cup in the crushing space is also provided with a detection device 9 electrically connected to the control board through a coupler (not shown in the figure). The detection device 9 can d...

Embodiment 3

[0056] Such as Figure 5 Shown is the third embodiment of the present invention. The difference from the previous embodiment is: in this embodiment, the cup body includes a first cup body 23 and a second cup body 24 detachably connected to the first cup body 23, and the second cup body 24 is located in the first cup body 23. Above the cup body 23, the enclosing member is the bottom wall 241 of the second cup body. The bottom wall 241 of the second cup body and the inner wall of the first cup body 23 enclose a crushing space and connect the external space with the crushing space. The communicating channel 51 is directly opened on the bottom wall 241 of the second cup body. Through the communicating channel 51, the water supplied into the second cup body 24 by the water supply system can flow into the first cup body 23 through the communicating channel 51 to achieve Blending of slurries.

[0057] In this structure, the crushing space is the internal space of the first cup, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com