Quadratic accelerating ultrasonic nebulization jet nozzle system for preparing copper powder

A secondary acceleration and atomization nozzle technology, which is applied in the field of nozzles and glands, can solve problems such as lack of speed, and achieve the effects of enhanced crushing force, less clogging, and uniform gaps in the ring seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

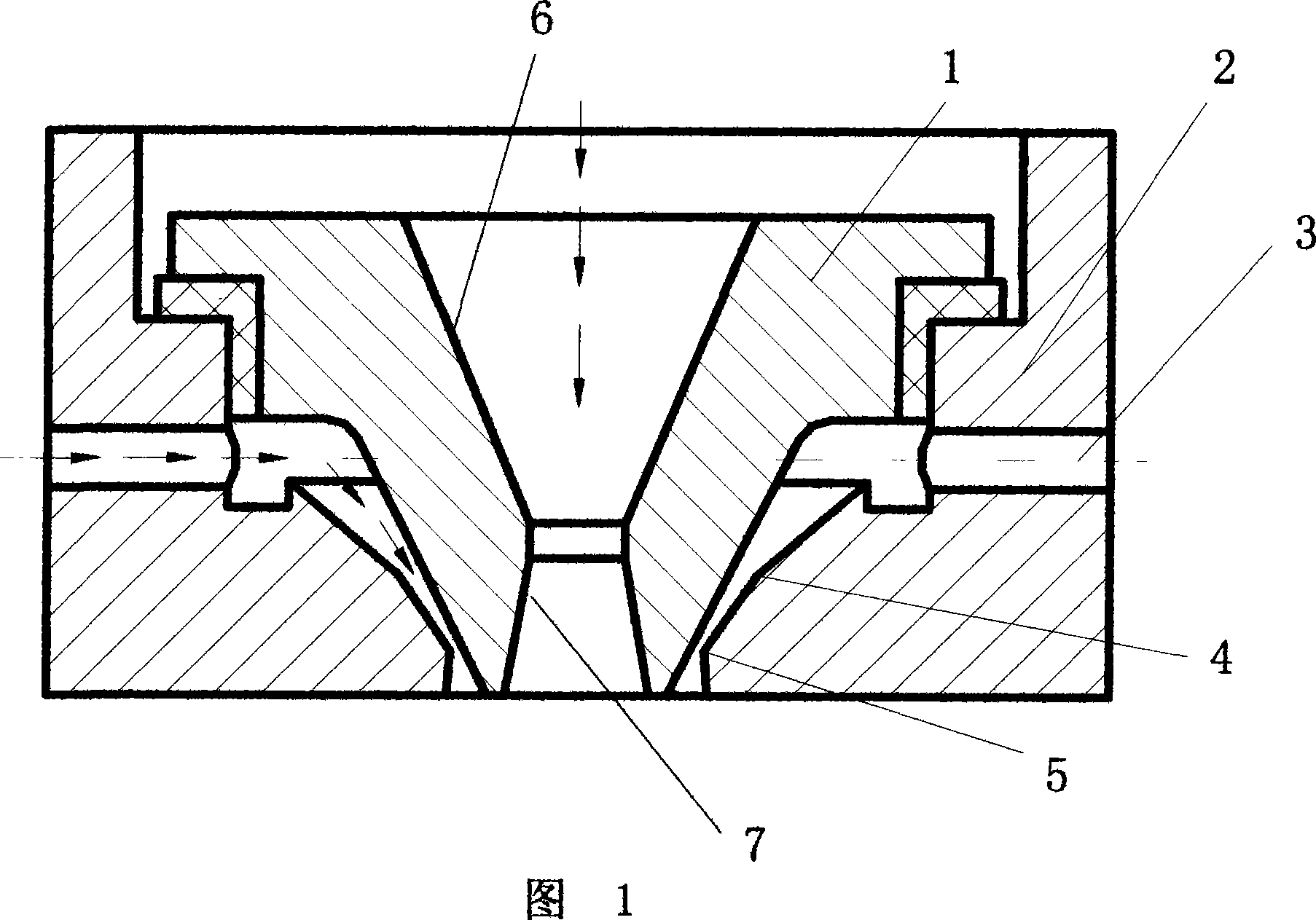

[0014] Nozzle 1: The length of the 6-cone inlet is designed to be 2.75 times that of the 7-cone outlet, the taper of the 6-cone inlet is 1:2.2, and the taper of the 7-cone outlet is 1:4. The included angle between the nozzle 1 and the vertical direction, that is, the top angle is designed to be 45 degrees.

[0015] Gland 2: There are two boss structures designed inside the gland 2, the angle between the boss structure A5 and the vertical direction, that is, the top angle is designed to be 40 degrees, and the angle between the boss structure B4 and the vertical direction, that is, the top The angle is designed to be 54 degrees.

[0016] The nozzle material is Cf / SiC composite material, and the heat insulation material and protective cover are made of FRC1-12 made of 22% boroaluminate fiber. The refractory composite heat insulation material.

[0017] Put the gland 2 on the nozzle 1, a medium channel 3 is formed between the nozzle 1 and the gland 2, the medium channel 3 forms a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com