Production method of low-alloy grain refinement type HRB400E reinforcing steel bar

A production method and grain refinement technology, applied in metal rolling, metal rolling, metal processing equipment, etc., to increase enterprise benefits, meet the needs of rapid development of the national economy, and ensure high-speed steel feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

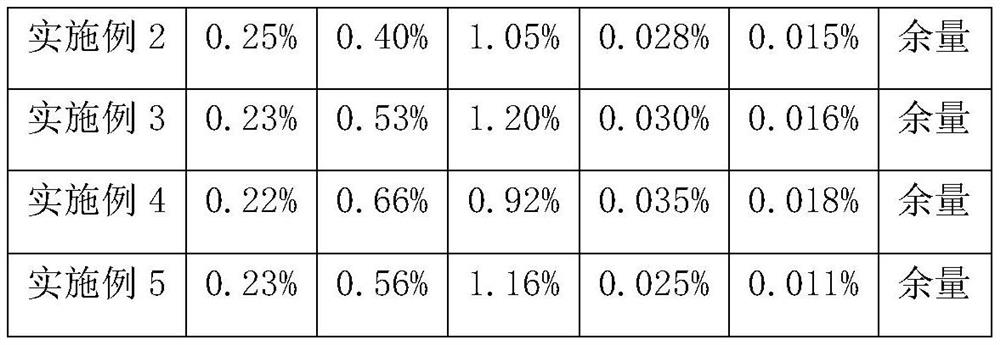

Examples

Embodiment

[0048] The present application provides a method for producing a low-alloy grain-refined HRB400E steel bar. The production method includes the following steps in sequence: heating a billet in a walking furnace, rough rolling, intermediate rolling, and pre-finishing. Pre-finishing is carried out on the rolling mill and is divided into two parts, one controlled cooling, one finishing rolling, two controlled cooling, two finishing rolling, water cooling, double-foot flying shear shearing, cooling on a cooling bed, and natural aging;

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com