Bale busting and crushing machine

A shredder and unbundling technology, which is applied in agricultural machinery and implements, cutting equipment, applications, etc., can solve the problems of poor uniformity, large influence on the output fineness and length of the straw bale unbundling shredder, and non-compliance with environmental protection requirements, etc. Achieve the effect of eliminating motor current fluctuations and equipment failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

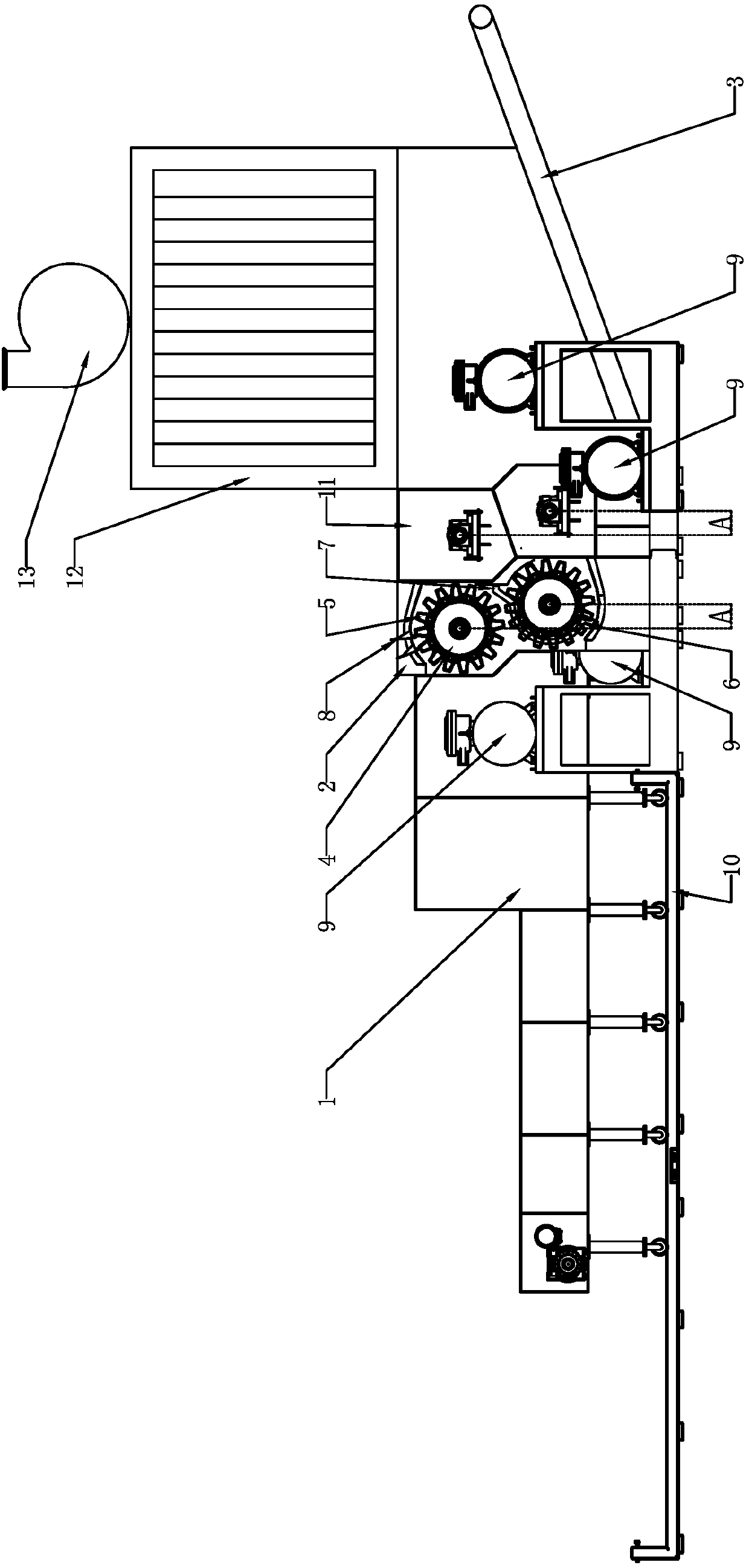

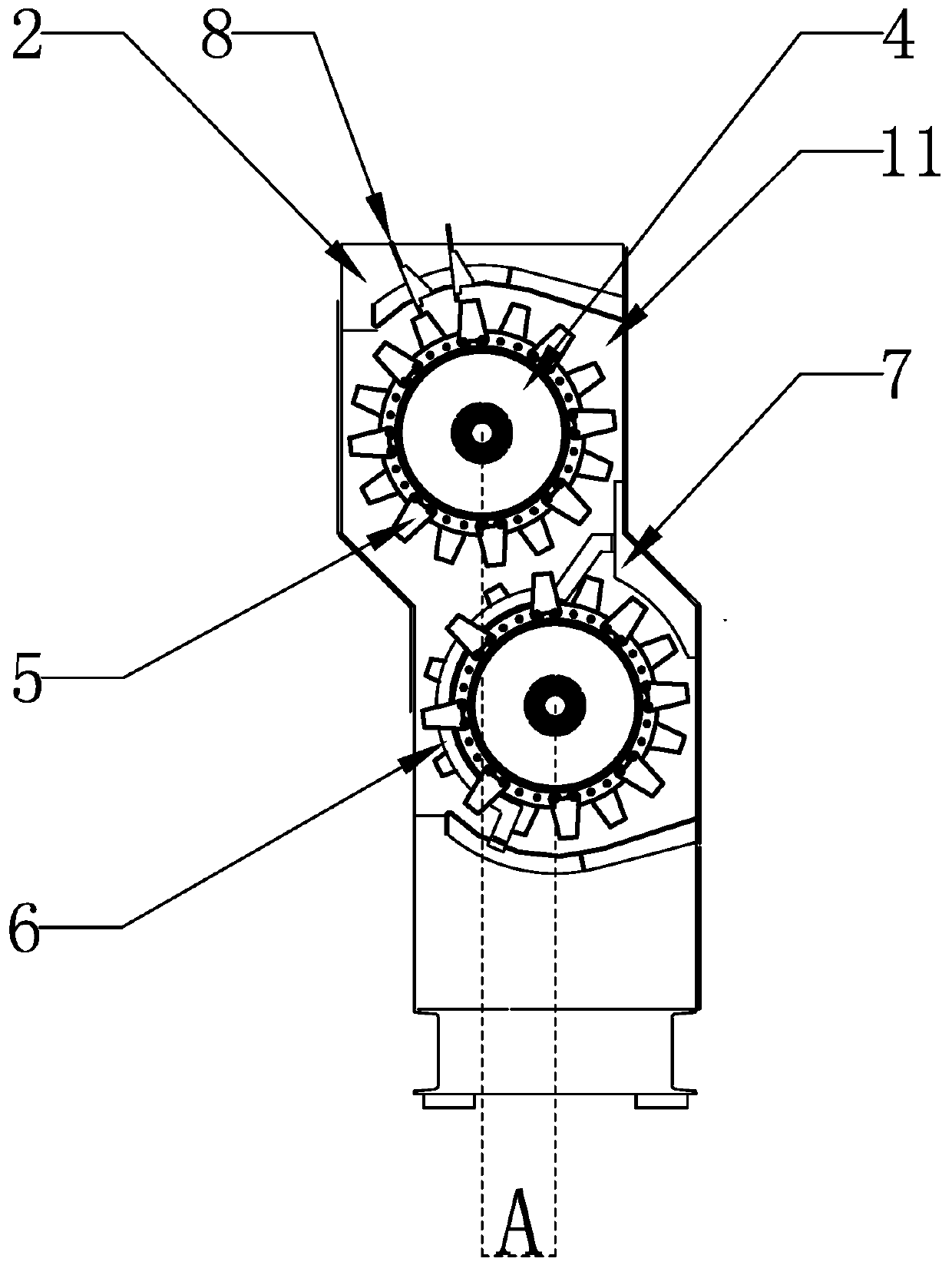

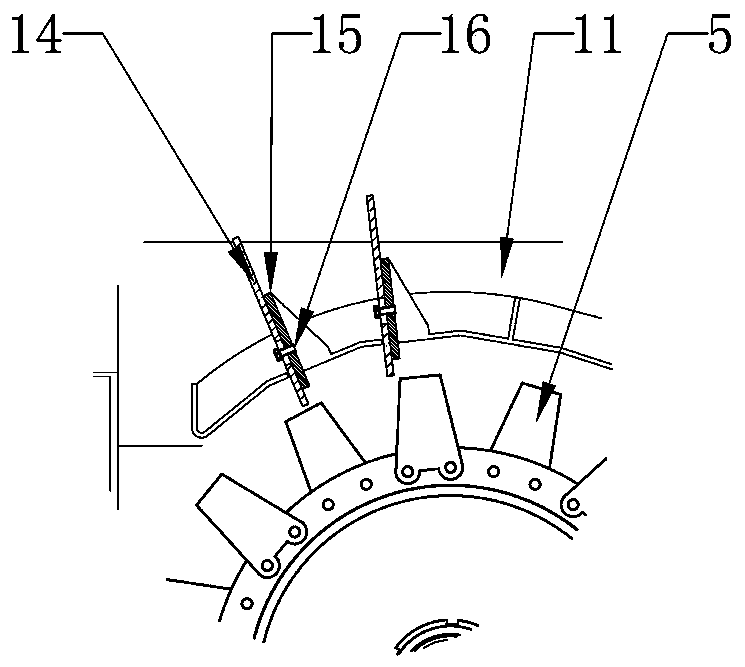

[0021] Example 1: figure 1 , a bale unbundling shredder, mainly composed of a feed conveyor (1), a shredder (2), and a discharge conveyor (3), wherein the shredder (2) consists of a rotor (4), a blade ( 5), motor (9) and pulverizer casing (11), characterized in that the feeding conveyor (1) feeds in a horizontal direction, its outlet dimension is the same as that of the pulverizer inlet, and the pulverizer rotor has two upper and lower parts. One rotor, two pulverizers are installed in series, the central axis of the upper rotor (3) of the pulverizer and the central axis of the lower rotor (3) are in the horizontal direction, and the displacement is 150 mm toward the entrance. When working, the feeding conveyor (1 ) into the bale, the upper layer of the flaky grass is first decomposed and crushed by the blade (5) of the upper rotor (4), so that when the lower layer of grass meets the lower rotor (4), the material of the upper layer is gone , avoiding the problem that the fora...

Embodiment 2

[0023] Embodiment 2, there are 3 pulverizers connected in series, and the blade (5) of the pulverizer is designed into a sheet shape, and the number of forks is 3 forks, a kind of bifurcation that is bent at a right angle, and the others are the same.

[0024] Beneficial effect:

[0025] When the patented bale unbundling machine of the present invention is in use, between two bales, the forage on the upper part of the flaky forage will not suddenly fall together, and will not cause motor current fluctuations and mechanical failures; eliminate the need for bale unbundling machines to be connected in series The defect of the structure makes the length of the grass stable and the uniformity improved when the output of the grass increases; it eliminates the return material; at the same time, it also solves the difficult problem of equipment maintenance caused by the series structure; it also solves the problem of large dust.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com