Automatic ultrasonic probe location method based on gasbag drive and air pressure detection

An ultrasonic probe and air pressure detection technology, which is applied in the direction of organ movement/change detection, ultrasonic/sonic/infrasonic Permian technology, ultrasonic/sonic/infrasonic image/data processing, etc., can solve the problem that the instrument is not suitable and affects the detection results , affecting accuracy and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

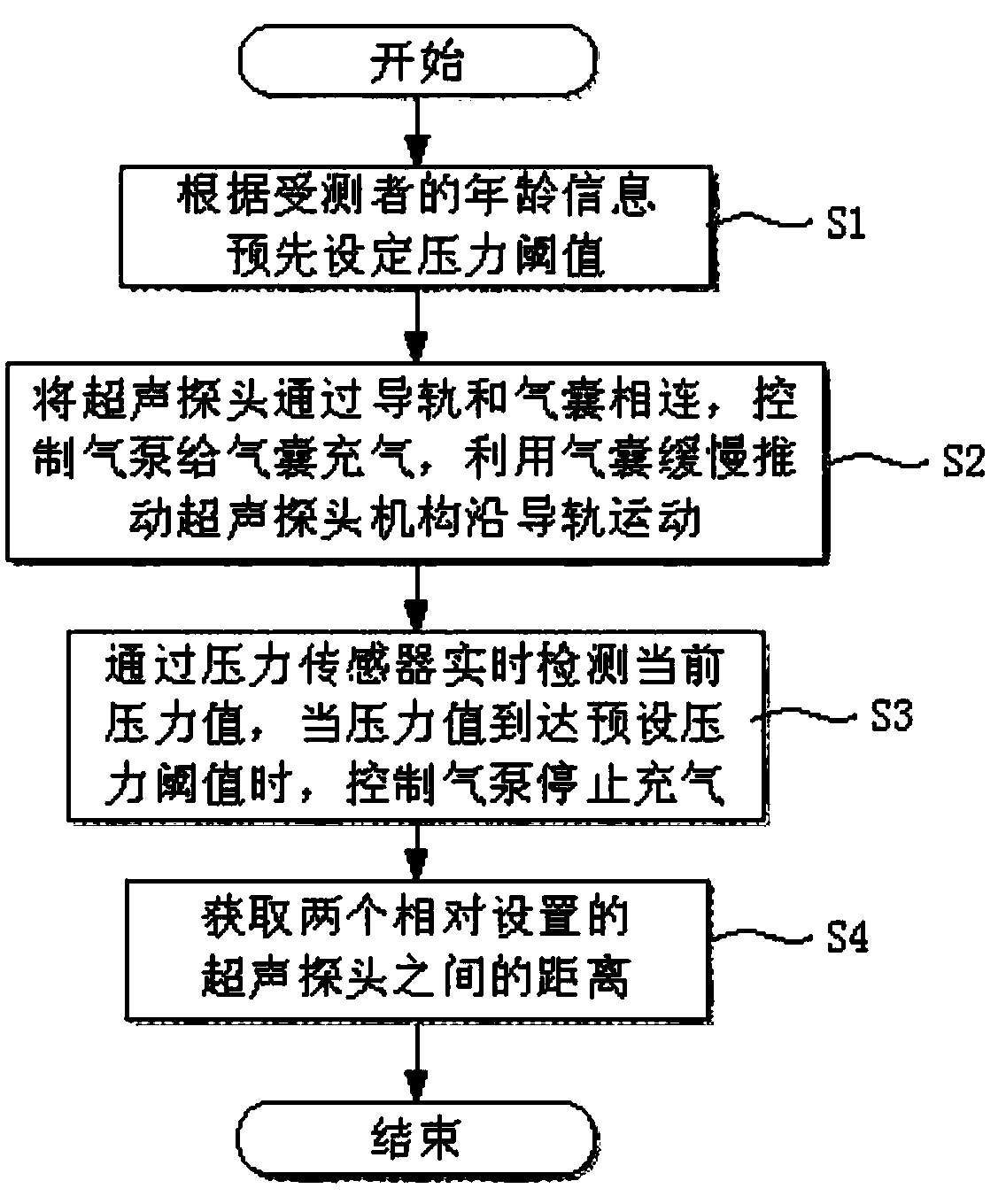

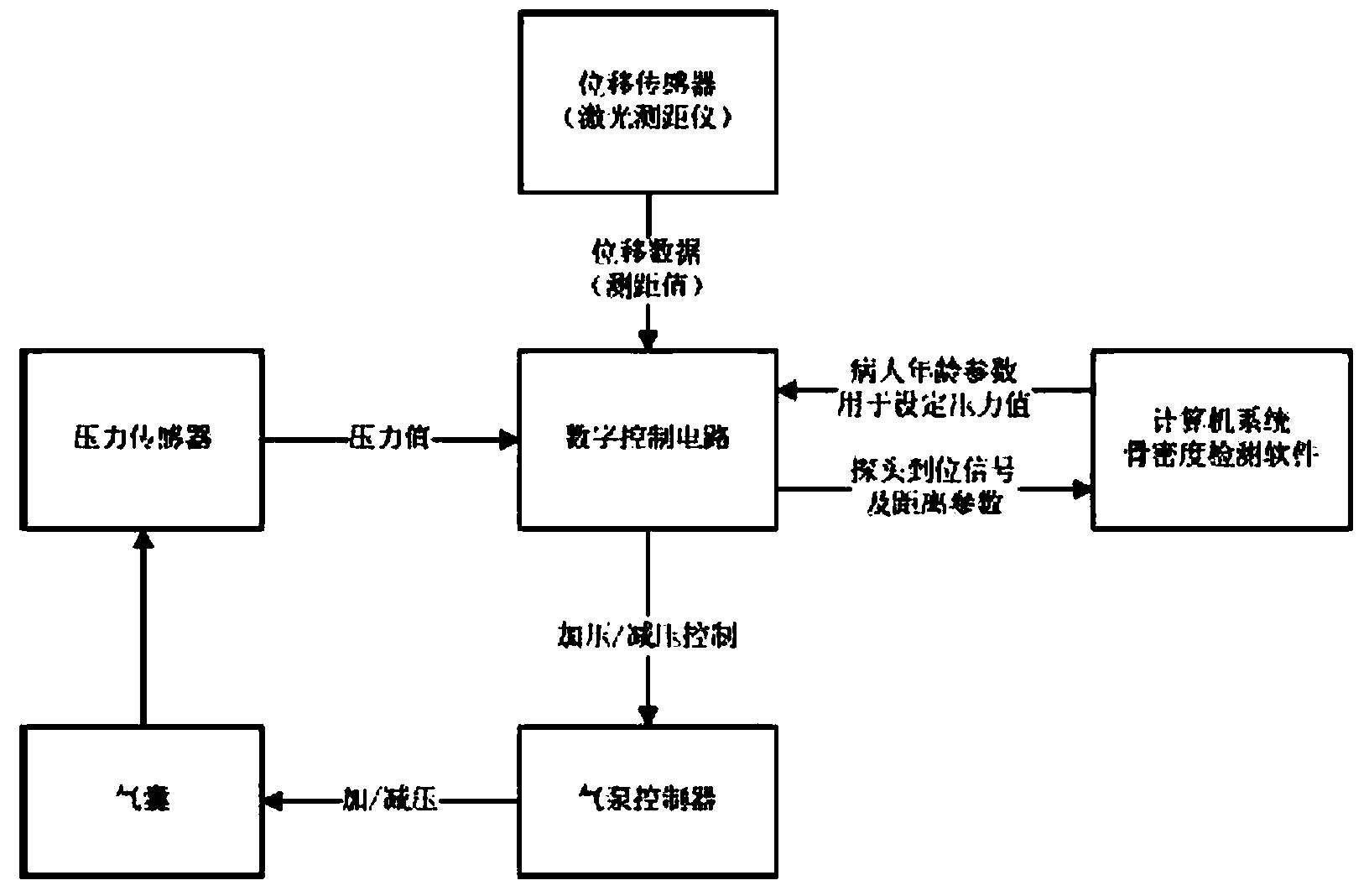

[0027] figure 1 It is a schematic diagram of the automatic positioning process of the ultrasonic probe based on the air bag pushing and air pressure detection in the present invention; figure 2 It is a schematic diagram of signal control interaction based on airbag push and air pressure detection in the present invention.

[0028] See figure 1 and figure 2 The method for automatic positioning of ultrasonic probes based on air bag push and air pressure detection provided by the present invention includes two relative ultrasonic probes, which includes the following steps:

[0029] Step S1: Preset the pressure threshold according to the age information of the subject; the age information of the subject is manually input or automatically obtained from the medical record management system through the network; the pressure threshold is proportional to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com