Disc slewing support method and slewing support for disc pelletizer

A disc pelletizing machine and slewing bearing technology, which is applied in the direction of granulation in the rotating disk/pot, can solve the problems of non-wearing, short service life, and unstable operation of the slewing bearing, and achieve improved contact strength and service life The effect of improving and improving the rotation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

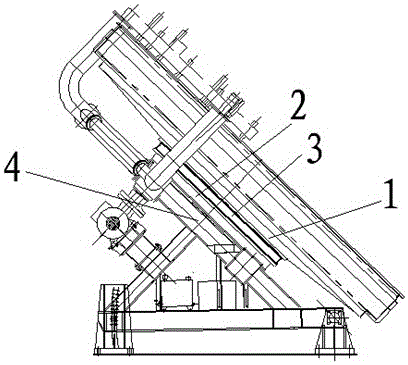

[0031] attached figure 1 An embodiment of the present invention is given, which is a slewing support for a disc pelletizing machine disc, including a disc pelletizing machine disc 1, a disc pelletizing machine base 2 and a disc pelletizing machine disc seat 3. Disc pelletizing machine seat 3 is installed on disc pelletizing machine base 2, disc pelletizing machine disc 1 is located on disc pelletizing machine disc seat 3, and on disc pelletizing machine disc 3 and the disk seat of the disc pelletizing machine is provided with a slewing support 4, and the disk 1 of the disc pelletizing machine can rotate around the center of the disc on the disk seat 3 of the disc pelletizing machine. It is characterized in that the The slewing bearing 4 is a three-row roller slewing bearing, and is installed on the end surface from the outer diameter to the center of the disc pelletizing machine.

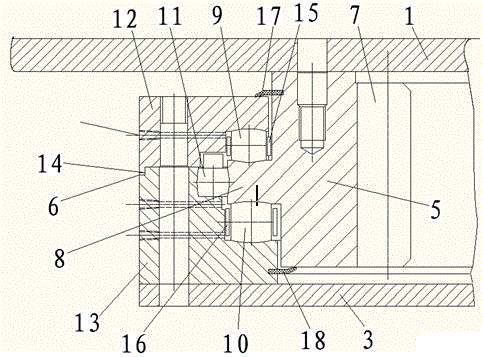

[0032] attached figure 2 A three-row roller slewing bearing 4 is given, including a rotating ...

Embodiment 2

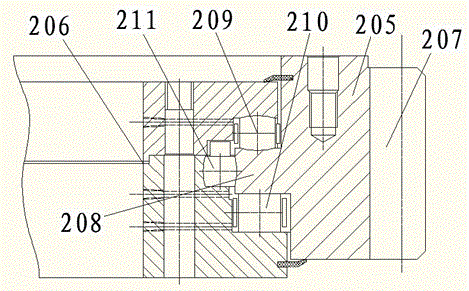

[0037] The structure of embodiment two is as attached image 3 As shown, its basic structure is the same as that of Embodiment 1, except that Embodiment 2 is a disk pelletizing machine with an outer ring gear, the ring gear is an outer ring gear 207, and the boss on the rotating disk 205 is an inner boss , the axes of the rotating disk 205 and the fixed disk 206 are just opposite to those of Embodiment 1, and only two rows of rollers 209 and 211 are spherical rollers among the three rows of rollers, and the other row of rollers 210 is flat rollers.

Embodiment 3

[0039] The structure of embodiment three is as attached Figure 4 As shown, its basic structure is the same as that of Embodiment 2, and it is also a disc pelletizing machine with an outer ring gear, except that the arrangement of the three rows of rollers is different. Two rows of rollers arranged radially, one row of rollers 309 are spherical rollers, the other row of rollers 310 are flat rollers, and the rollers 311 arranged on the circumference are also spherical rollers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com