Continuous circulation type coal crushing equipment

A technology for crushing coal and raw coal, applied in grain processing and other directions, can solve the problems of difficult cleaning of residues, low combustion efficiency, increased pollutants, etc., and achieve the effects of shortening processing time, reducing waste of transportation capacity, and reducing the degree of pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

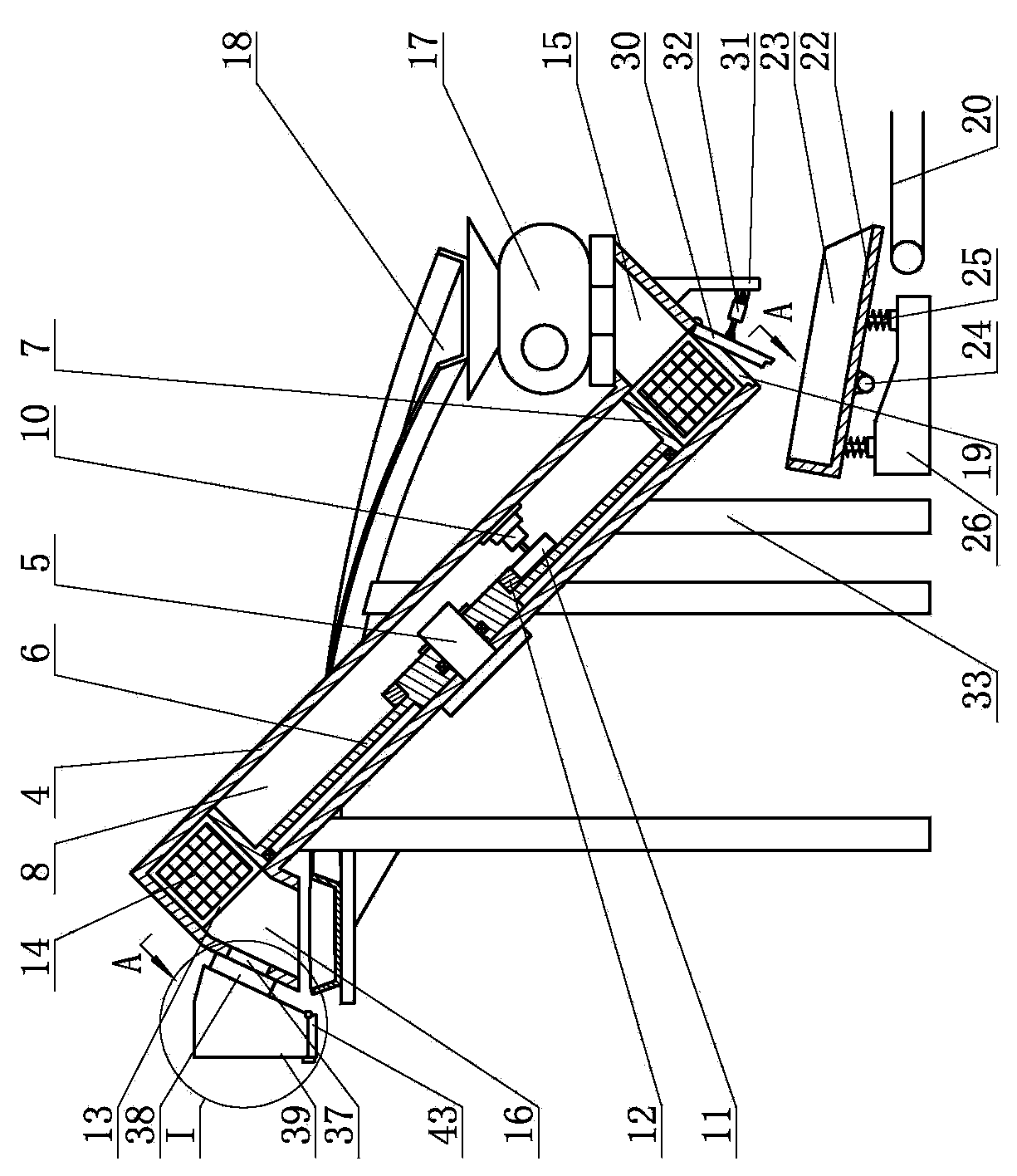

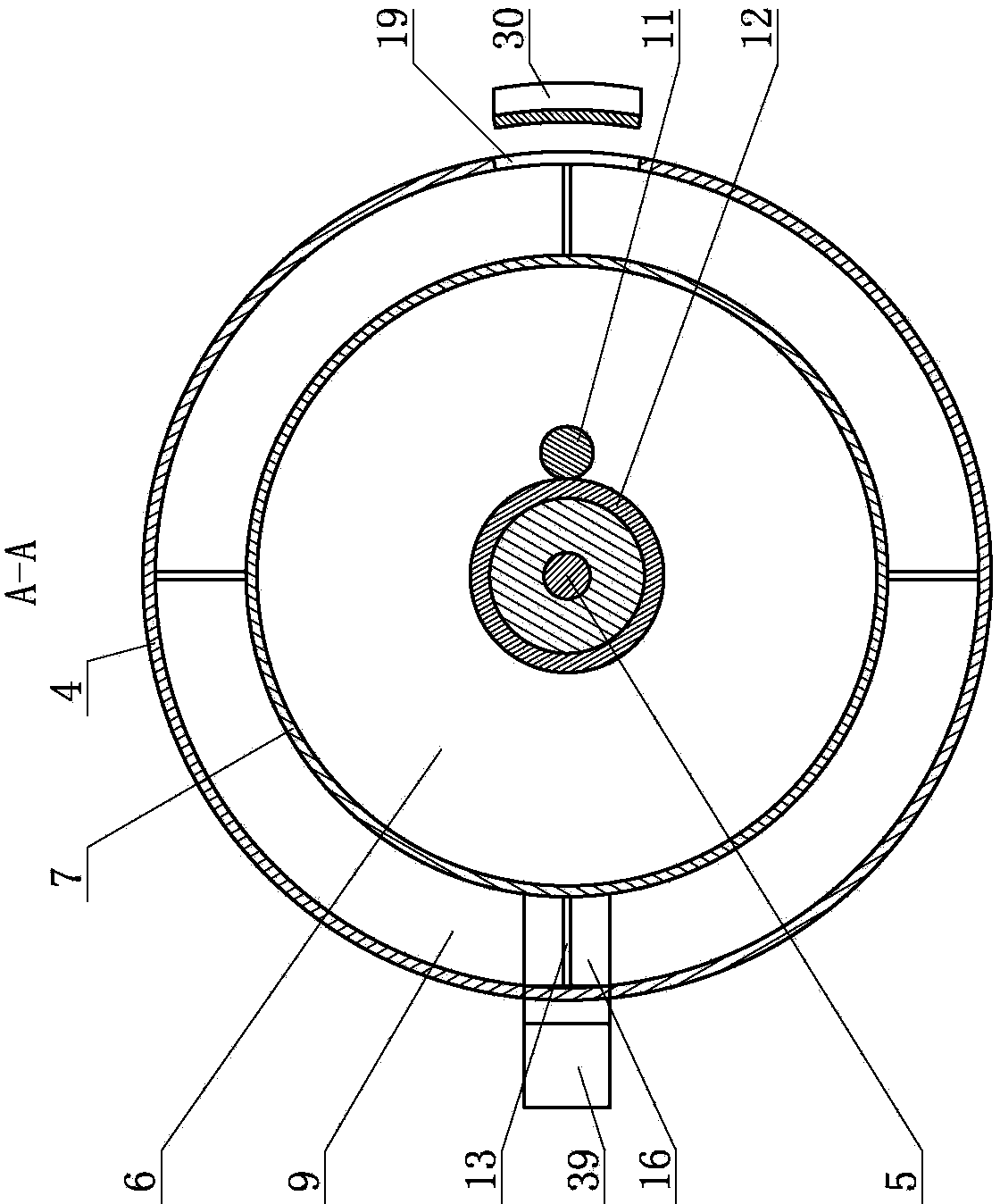

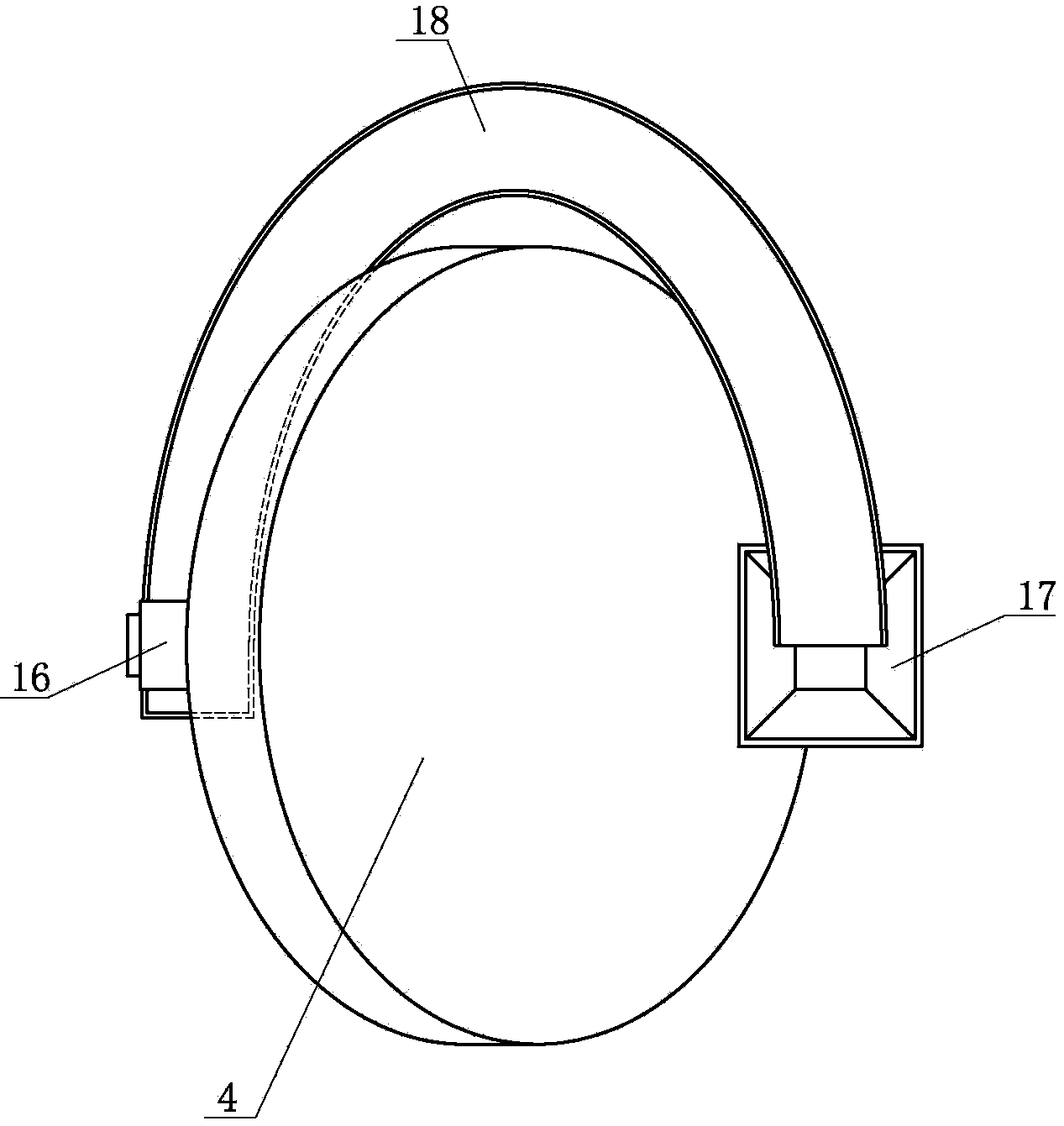

[0011] A kind of continuous circulation coal crushing equipment described in the present invention comprises classifier and raw coal crusher 17, and classifier has a shell 4 of hollow disc shape, and shell 4 comprises two mutually parallel circular side walls, The circumference of the two circular side walls is connected by an annular side wall. The two circular side walls of the housing 4 are both inclined 30°-60° relative to the horizontal plane. The turntable 6 is installed on the top, the turntable 6 can rotate around the central axis 5, the outer edge of the turntable 6 is provided with an isolation ring 7, and the isolation ring 7 separates the housing 4 into a disc-shaped cavity 8 in the middle and an annular cavity 9 in the outer periphery. A driving motor 10 is arranged in the cavity 8, and the driving motor 10 is fixedly installed on the inner wall of the housing 4. The driving gear 11 is installed on the output shaft of the driving motor 10, and the gear ring 12 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com