Crushing and transportation method and crushing and transportation system of deep mining ore

A transportation system and ore crushing technology, which is applied in the field of mining and dressing, can solve the problems of high operating cost, reduced effective load, and complicated process of the dressing plant, so as to avoid material blocking at the head or tail of the machine, save ground land resources, The effect of good ore fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

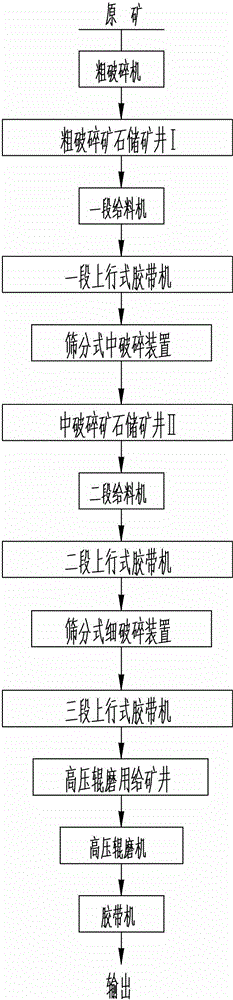

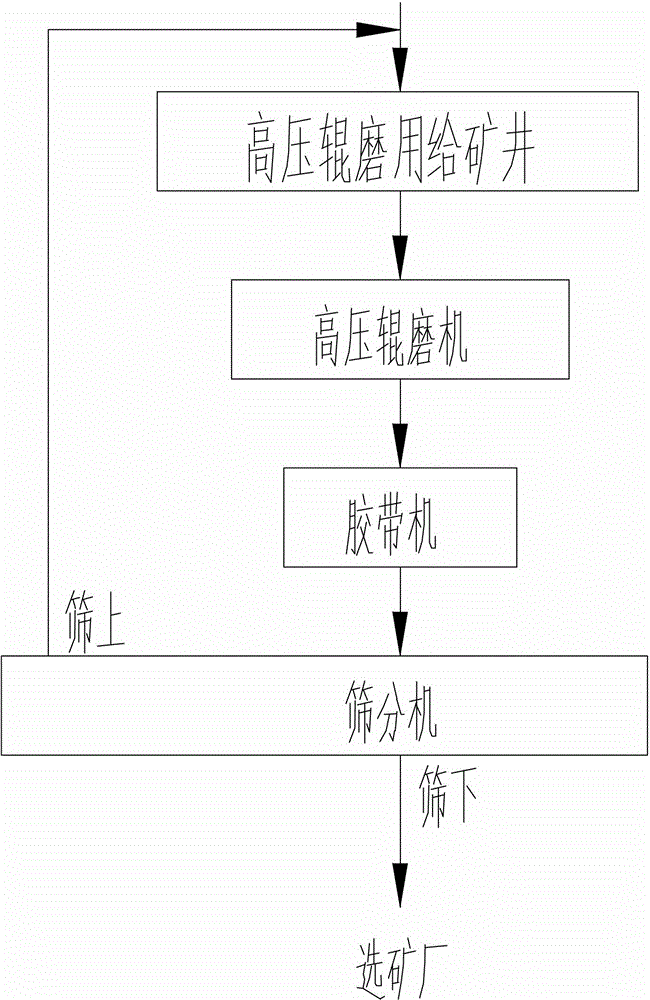

[0020] Such as figure 1 Shown, the crushing transportation method of deep mining ore of the present invention comprises the following steps:

[0021] 1) Feed the raw ore ≤ 1200mm into the coarse crusher, and the ore is crushed to ≤ 400mm and then sent to the coarse crushing ore storage shaft I, and then fed into the first section of the feeder through the coarse crushing ore storage shaft I, and the first section feeder will ≤ 400mm The ore is sent to an ascending belt conveyor;

[0022] 2) A section of upward belt conveyor feeds ≤400mm ore into a set of screening type medium crushing device, and after being screened by the screening type medium crushing device, ≤150mm ore directly falls into medium crushing ore storage shaft II, while ≤400, The ore ≥ 150mm is crushed in the screening type intermediate crushing device. After the ore is crushed to ≤ 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com