Edge grinding printing device of firework rolling machine

A printing device and reel machine technology, applied in printing, printing machines, rotary printing machines, etc., can solve problems such as failure to meet market demand, troublesome production of pasted leather paper, uneven outer wall of paper tubes, etc., and achieve accurate and reliable adjustment methods. Saving process, practical and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

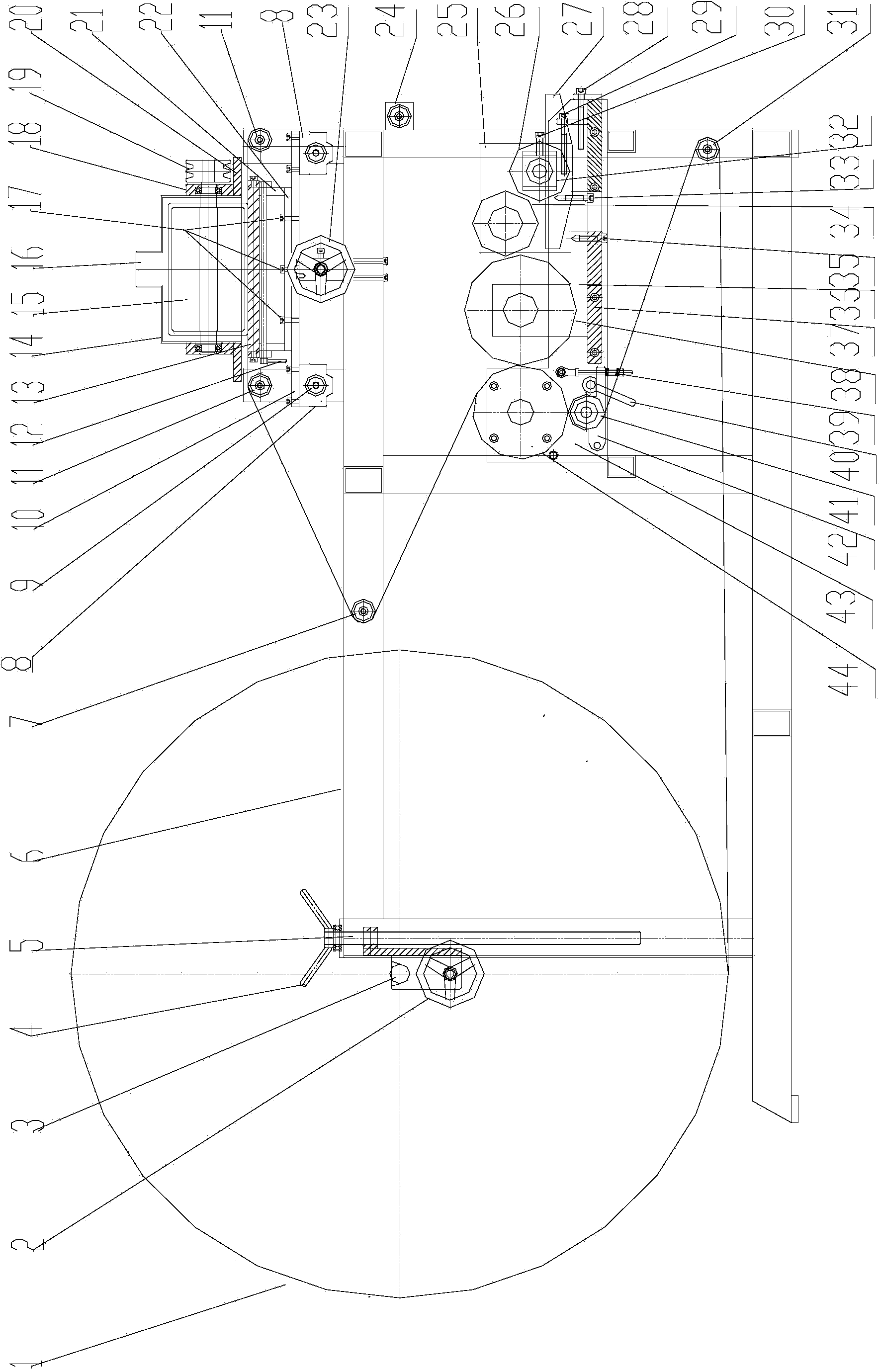

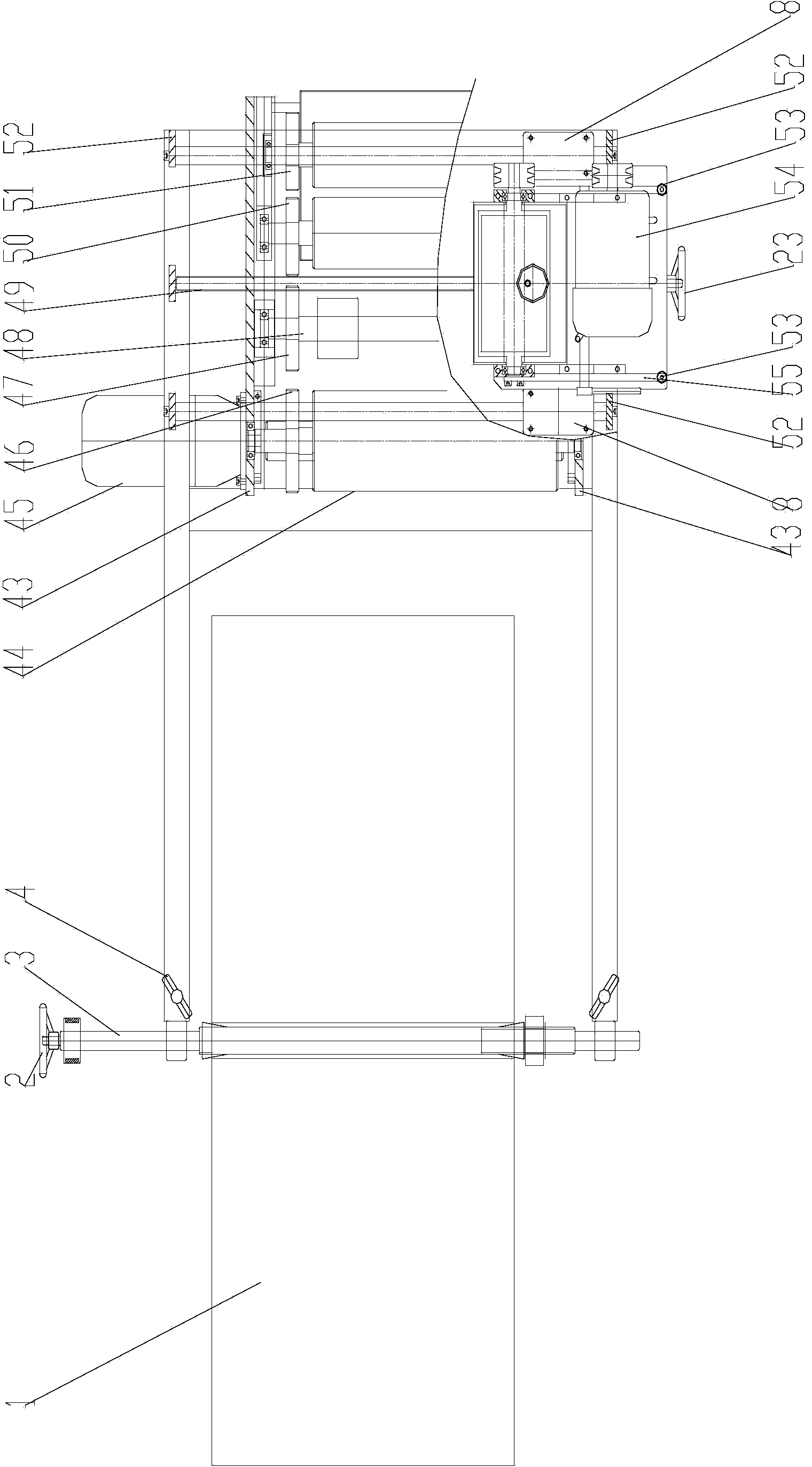

[0023] Referring to the accompanying drawings, it reflects a specific structure of the present invention. The base paper edging printing paper loading device is mainly used for supporting facilities of the firecracker reel machine, and includes a paper loading frame, a printing mechanism, a grinding machine installed on the frame according to the working order. side agency:

[0024] The upper paper rack includes an upper paper shaft 3 that carries the reel base paper 1, and the upper paper shaft 3 is provided with a roll paper left and right adjustment assembly and a height adjustment screw assembly; the roll paper left and right adjustment assembly includes a base paper that is connected to a slider to move The handle 2 and the slide block are mounted on the upper paper shaft 3, driven by a screw mandrel, which is driven by moving the handle 2 left and right, and the left and right positions of the roll paper can be adjusted by turning the handle 2.

[0025] The height adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com