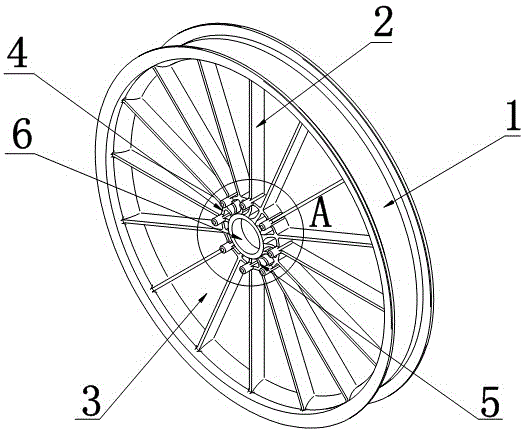

A wheel hub structure made of composite plastic

A technology of composite plastics and hubs, which is applied to wheels, wheels, and vehicle parts made of non-metallic materials. It can solve the problems of high processing cost, low strength, and heavy weight, and achieve high processing efficiency, low apparent density, and structural stability. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

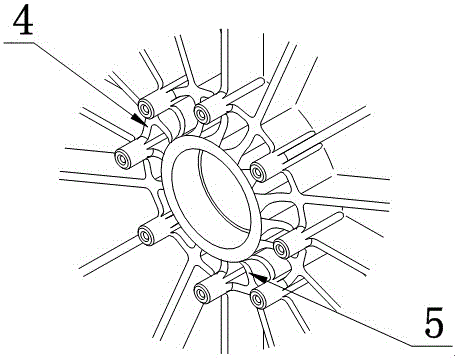

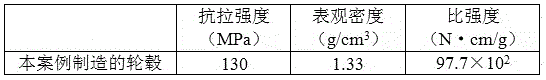

[0031] The invention provides a new type of composite plastic for manufacturing a wheel hub, and a wheel hub made of the composite plastic which is different from the structure of the existing wheel hub. The novel composite plastic designed by the present invention is composed of 48%-79% polypropylene, 20%-50% glass fiber after surface activation treatment and 1%-2% plastic auxiliary agent, and the glass fiber can be It can be long glass fiber or short glass fiber, depending on the actual situation. The plastic auxiliary agent is used to further enhance the performance of the composite plastic, and it can be an anti-aging agent; it can also be composed of an anti-aging agent and a dyeing agent, and the ratio of the two is determined according to the actual production needs of the manufacturer. Adding an anti-aging agent can further enhance the anti-aging ability of the wheel hub, and adding a dye can make the wheel hub appear in various colors, bright and beautiful in appearan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap