Apparatus for replacing tuyere small sleeve

A small tuyere cover and blast furnace technology, applied in the direction of the tuyere, can solve the problems of small tuyere cover replacement, water leakage, bad working environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

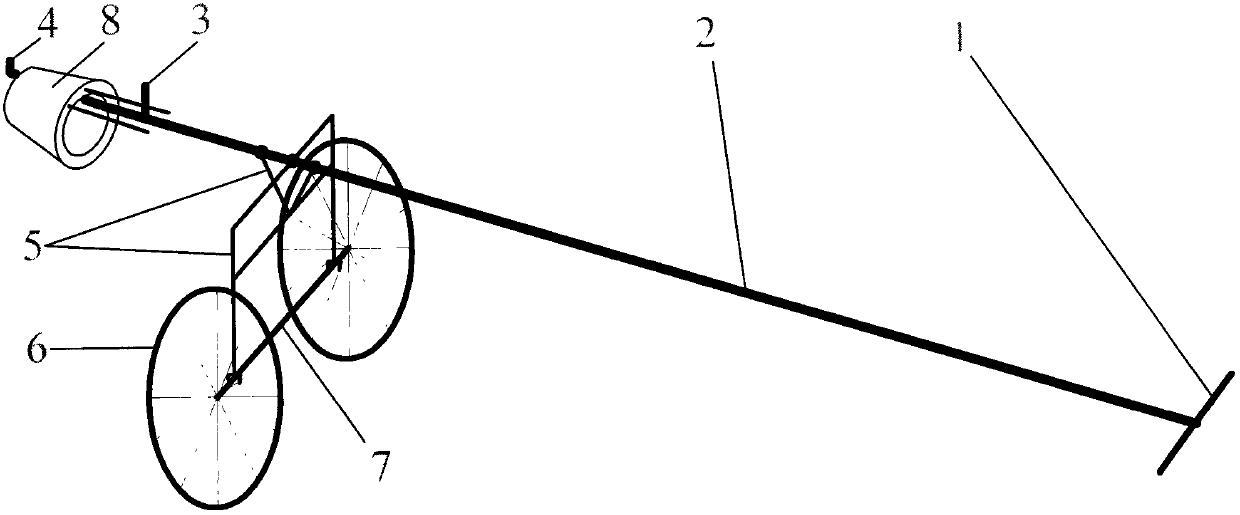

[0015] See attached picture. This device is realized by utilizing the principle of leverage, and the crowbar 2 is a lever, and the vehicle frame 5 and the wheel 6 are fulcrums. The small tuyere cover 8 of the blast furnace air supply device is located inside the middle cover of the tuyere. When the damaged small cover 8 of the tuyere needs to be disassembled, first the small cover 8 of the tuyere is removed from the middle cover of the tuyere, and then the front end of the crowbar 2 is inserted into the small cover 8 of the tuyere. , press handrail 1 down, make tuyere small cover 8 hang on crowbar 2 front ends, pull away this device, tuyere small cover 8 is generally transported to designated position.

[0016] After the damaged air outlet cover 8 is disassembled, when it is necessary to install a new air outlet cover 8, insert the front end of the crowbar 2 into the new air outlet cover 8, press down on the handrail 1, and make the new air outlet cover 8 hang on the front end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com