1*7I prestress wire

A technology of prestressed steel strands and steel strands, applied in textiles, papermaking, textile cables, etc., can solve the problems of core wire edge slip and retraction, core wire stress reduction, stress concentration, etc., to increase effective friction strength, improved quality and life, the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

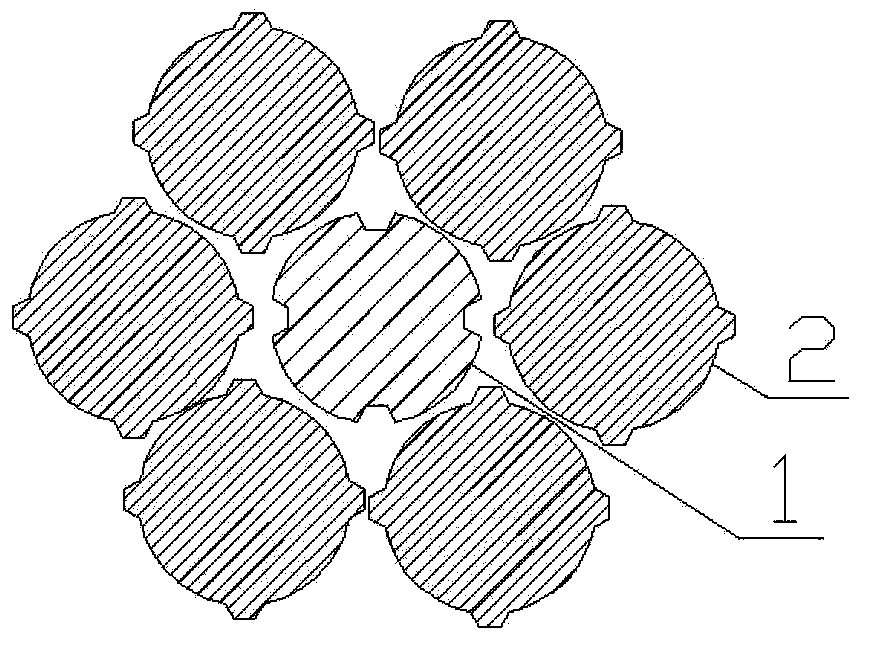

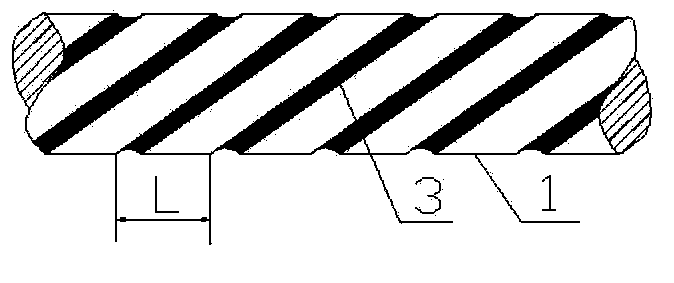

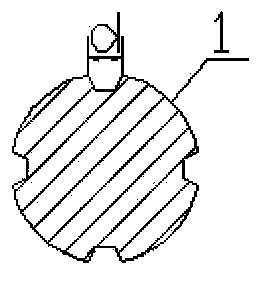

[0025] Referring to the illustration, a 1×7I prestressed steel strand is twisted from a core wire 1 in the center and six side wires 2 in the outer layer. The surface of the core wire 1 has four parallel and spirally wound The spiral groove 3, the surface of the side wire 2 has four parallel spiral ribs 4 that surround in a spiral shape, the sections of the spiral groove 3 and the spiral rib 4 are both trapezoidal, and the width d of the spiral groove 3 and the spiral rib 4 is 0.9~3.0 mm, and the lead L is 24~58mm.

[0026] The above-mentioned contents are only preferred embodiments of the present invention, and should not be considered as limiting the implementation scope of the present invention. All equivalent changes and improvements made according to the application scope of the present invention shall still belong to the scope covered by the pate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com