Anti-wear insulation pipe nipple for electromagnetic wave measurement while drilling

A technology of measuring while drilling and insulating pup joints, which is applied in construction and other directions, can solve the problems of time-consuming and laborious cleaning, and achieve the effects of simple repair work, reduced damage, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

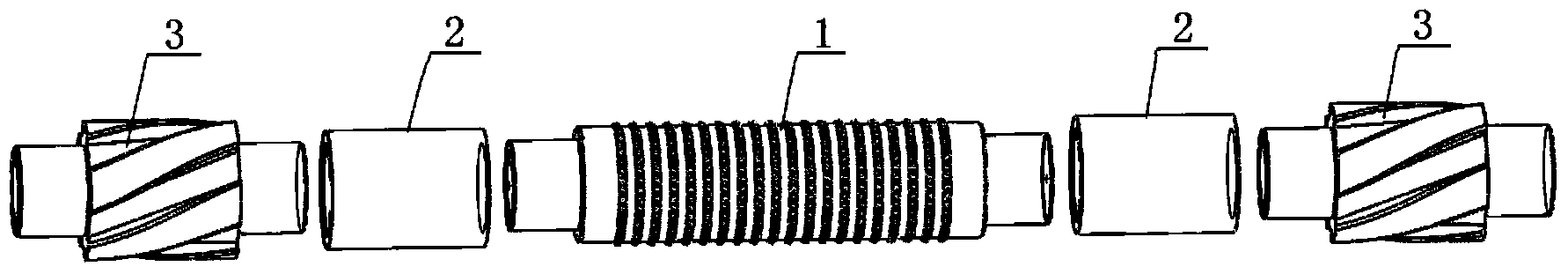

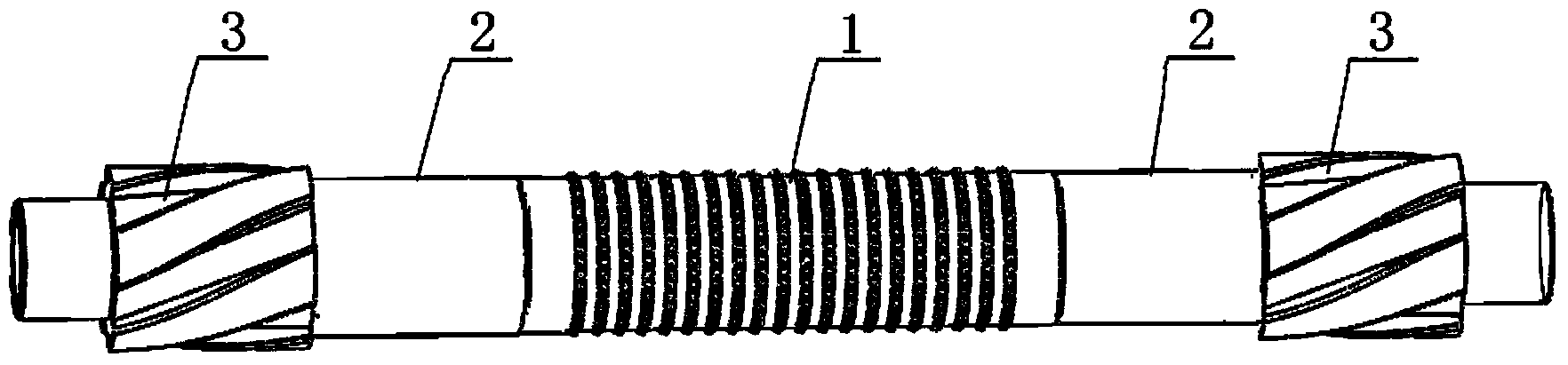

[0023] Embodiment 1: The present invention provides an electromagnetic wave measurement while drilling an anti-wear insulating pup joint, its structure is as follows figure 1 , 2 with image 3 As shown, it includes the pup body 1 with a central through hole, the protection joint 2 and the anti-wear joint 3; As the center, the two ends are symmetrically connected to the protective joint 2 and the anti-wear joint 3 through threads respectively.

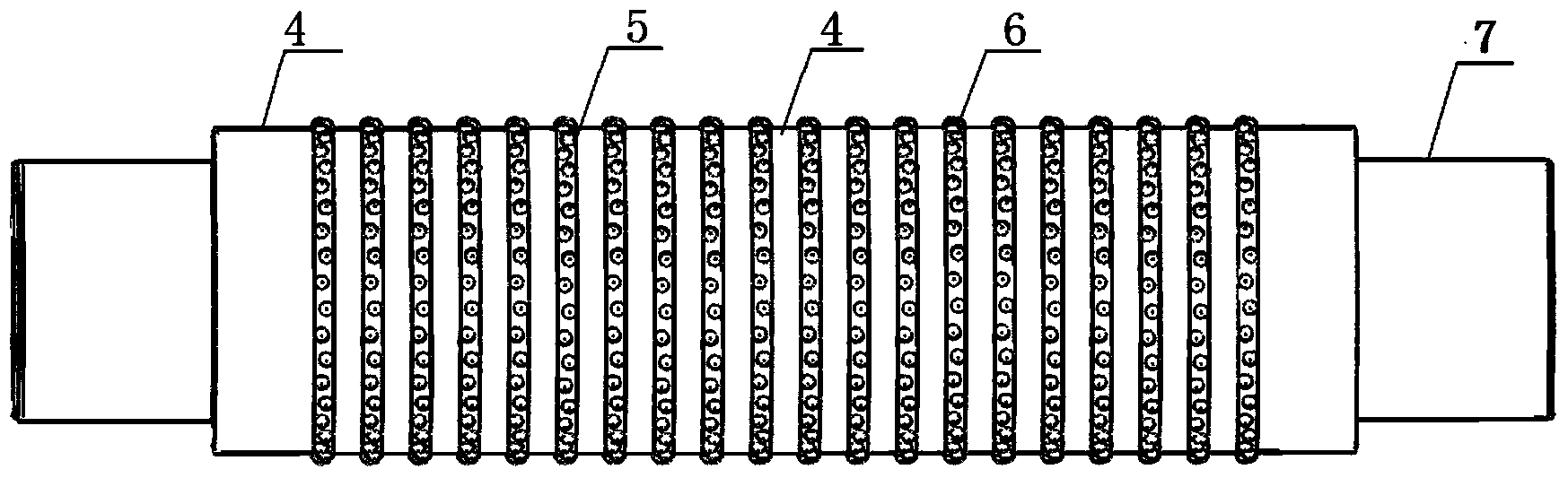

[0024] The length of the short joint body 1 is 765 mm, the outer diameter of the protective tape 5 is 175 mm, the outer diameter of the insulating tape 4 is 159 mm, the inner diameter of the short joint body is 89 mm, and the outer surface of the short joint body 1 is evenly divided into interval Insulating tape 4, the insulating tape 4 distributed at intervals is a groove with a large width at both ends and a small width in the middle section processed earlier, the grooves at both ends and the groove in the middle section are grooves...

Embodiment 2

[0027] Embodiment 2: The present invention provides an electromagnetic wave measurement while drilling an anti-wear insulating pup joint. Its structure is the same as that of Embodiment 1, except that the dimensions of each component change. In this embodiment, the short joint body 1 has a length of 530mm, the outer diameter of the protective tape 5 is 103mm, the outer diameter of the insulating tape is 89mm, the depth of the groove is 8.5mm, the inner diameter of the short joint body is 69mm, the width of the insulating tape at both ends is 50mm, and each annular insulation in the middle section The belt width is 20mm, and the width of each annular protective belt is 10mm. The flexible ceramics are CeRam-Kote2000. The thickness of the flexible ceramic insulating layer on the surface of the insulating tape is 1 mm, and the thickness of the glass fiber reinforced plastic insulating layer is 2 mm; the thickness of the flexible ceramic layer sprayed on the inner surface of the nip...

Embodiment 3

[0029] Embodiment 3: The present invention provides an electromagnetic wave measurement while drilling an anti-wear insulating sub. Its structure and flexible ceramics used are the same as in Embodiment 2. The difference is that the length of the insulating sub body 1 of this embodiment is 465 mm, and the outer diameter of the protective tape 5 is The outer diameter of the insulating tape is 81.6mm, the outer diameter of the insulating tape is 73mm, the depth of the groove is 4mm, the inner diameter of the pup joint body is 53mm, the width of the insulating tape at both ends is 40mm, the width of each annular intermediate insulating tape is 15mm, and the width of each annular protective tape is 5mm. The thickness of the flexible ceramic insulating layer with surface is 0.2mm, the thickness of the FRP insulating layer is 1mm; the thickness of the flexible ceramic layer on the threaded surface of the pup joint body is 0.2mm, and the thickness of the flexible ceramic layer on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com