Injection type hollow resin anchor bar

An internal injection and bolt technology, which is used in the installation of bolts, mining equipment, earth-moving drilling, etc., can solve the problems of large pushing resistance, difficult to push the bolt to the bottom of the hole to install in place, and unreasonable force on the bolt. , to achieve the effect of reasonable stress on the anchor rod, simplify the anchoring construction operation, and reduce the maintenance workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

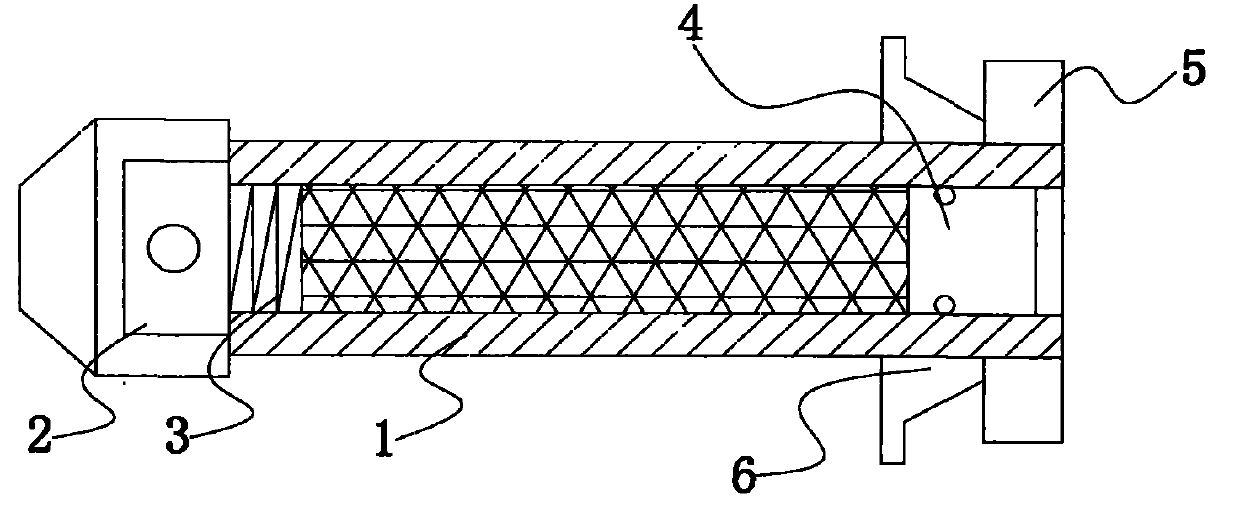

[0014] see figure 1 , the specific embodiment is realized by adopting the following technical scheme, which includes an anchor body 1, an anchor head 2, a mixer 3, a piston 4 and a nut 5; the outer wall of the anchor body 1 is provided with a long external thread , the inside of which is provided with a hollow medicament cavity, the front end of the anchor body 1 is provided with an anchor head 2, and the rear end is screwed and matched with the external thread on the surface of the anchor body 1 through a nut 5, the medicament cavity One end is provided with a piston 4 that fits the inner wall of the medicine chamber, and the other end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com