Light guide plate and backlight module using light guide plate

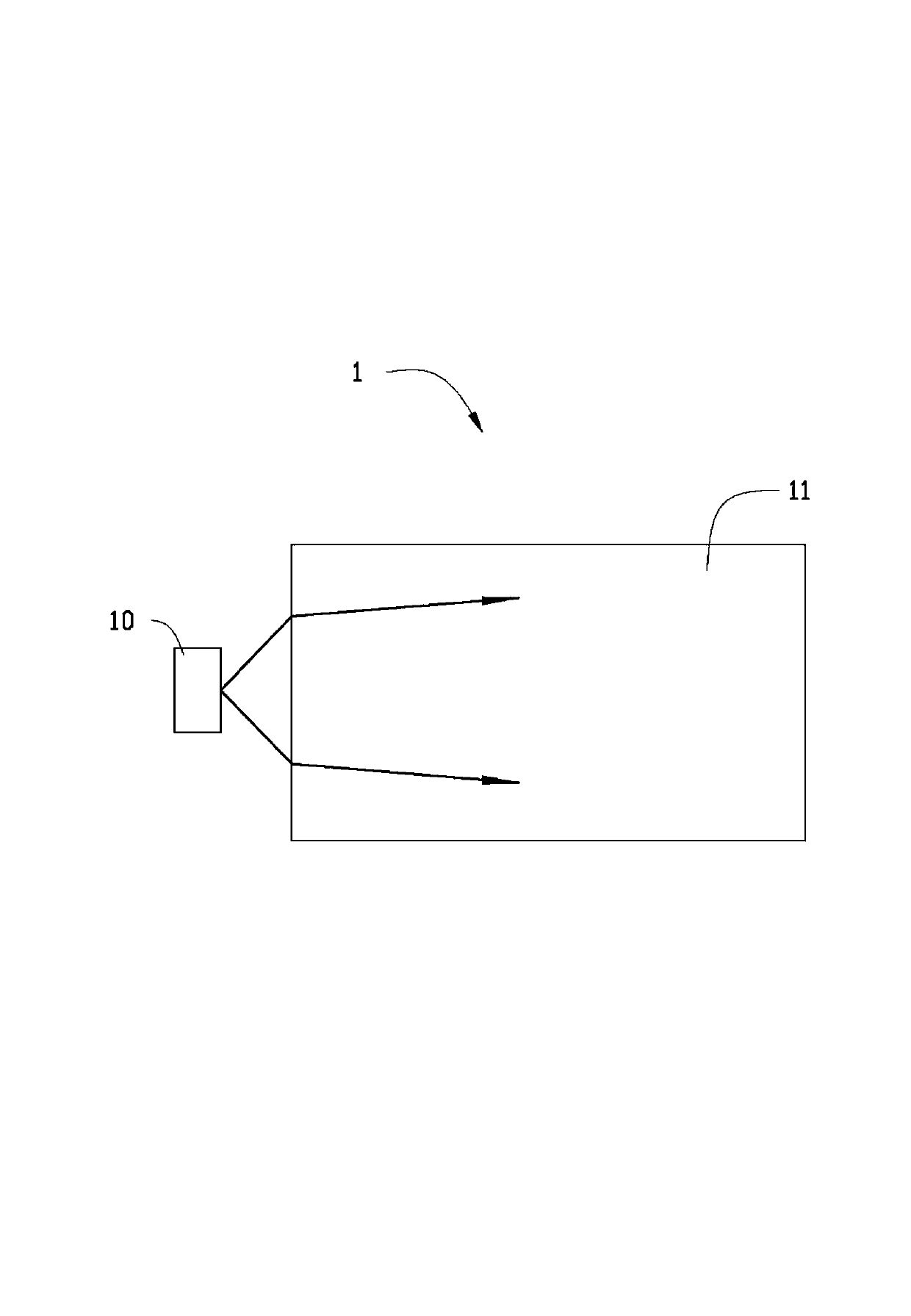

A technology of backlight module and light guide plate, which is applied in the directions of optics, light guide, light source, etc., can solve the problems of reducing the diffusion angle and reducing the light utilization rate of the light guide plate 11, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

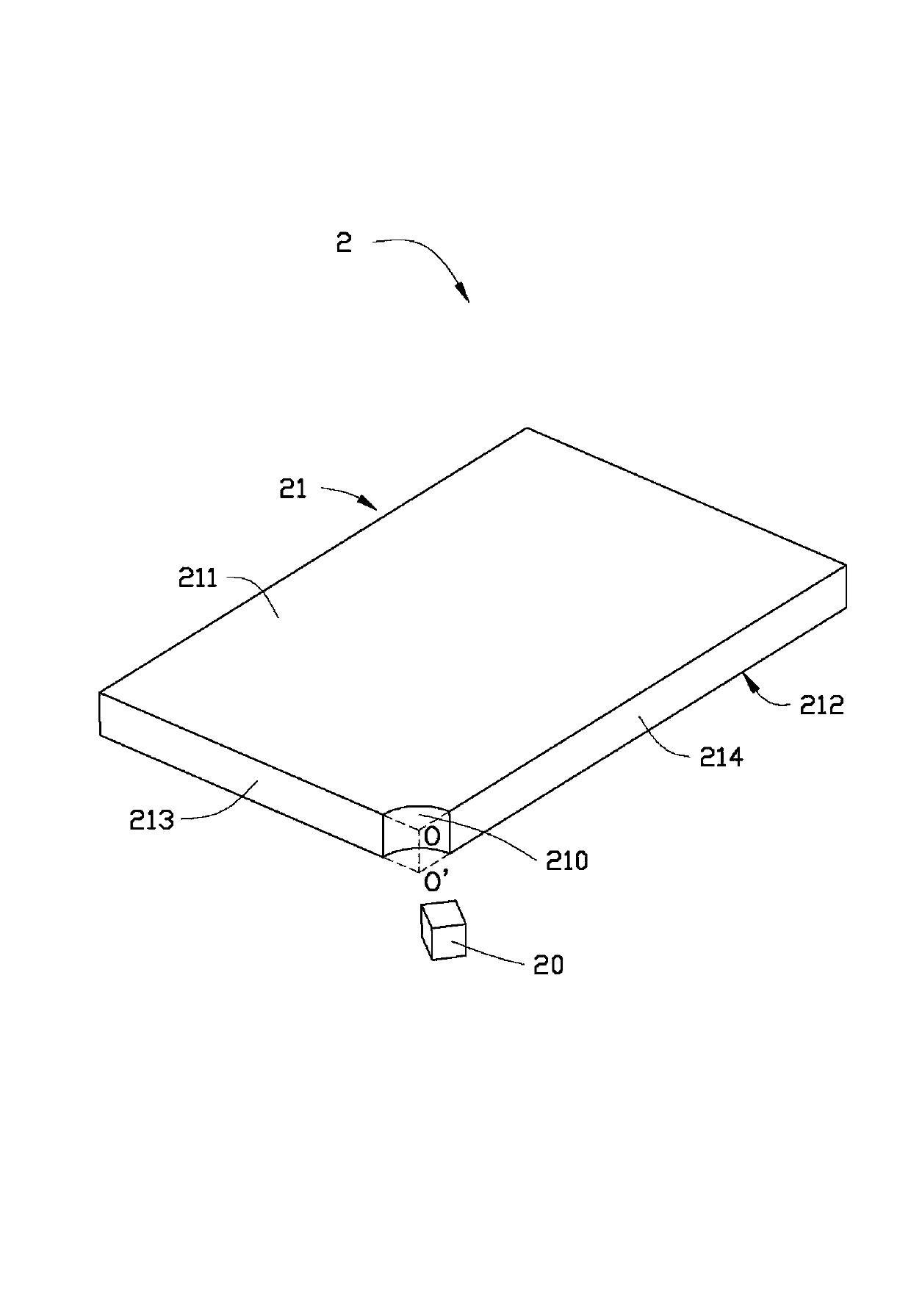

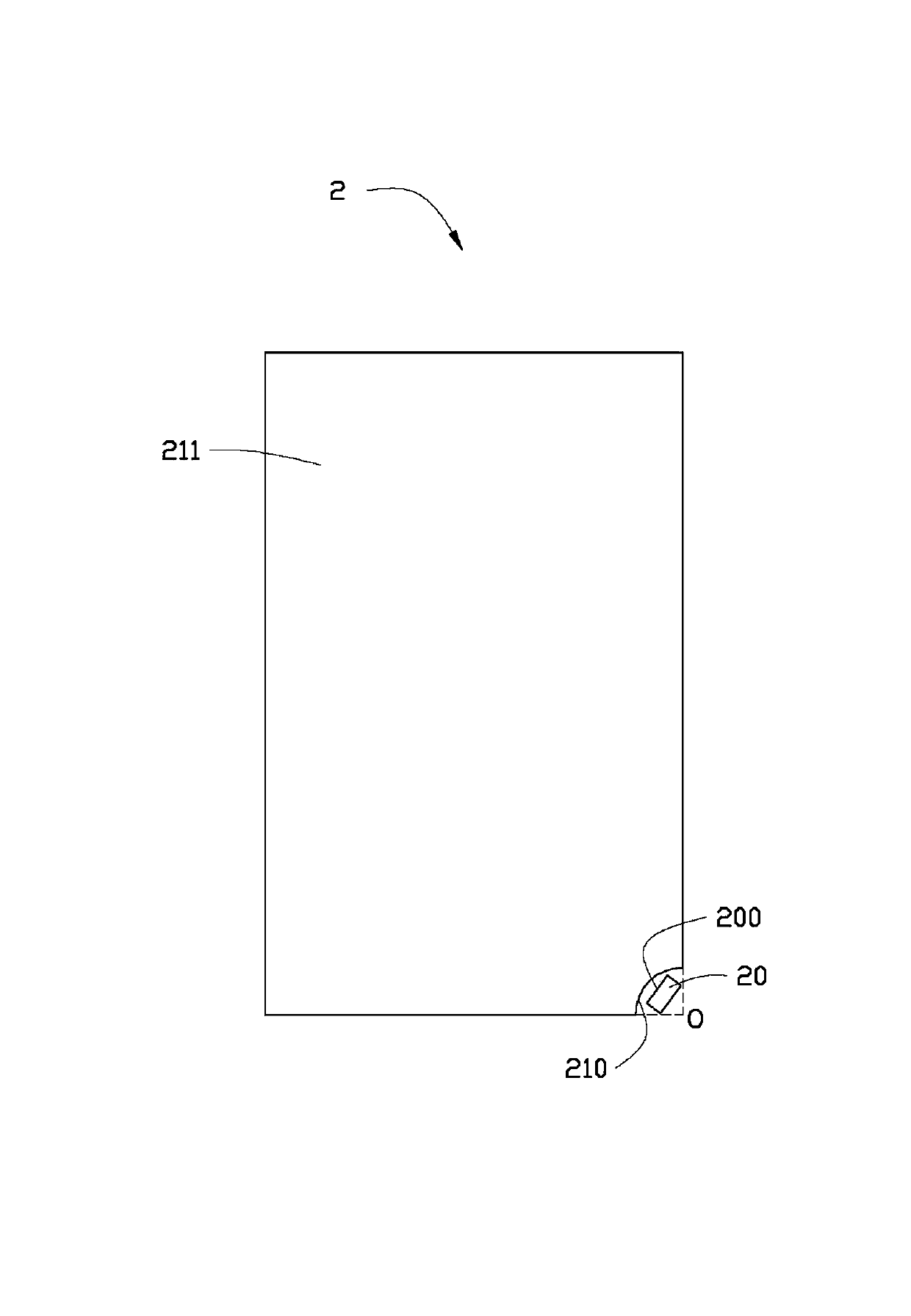

[0020] see Figure 2 to Figure 4 , the backlight module 2 of the first embodiment of the present invention includes a light guide plate 21 and an LED light source 20 disposed facing the light guide plate 21 . The LED light source 20 is used to generate incident light beams entering the light guide plate 21 . The light guide plate 21 includes a light incident surface 210 for receiving incident light beams, a light exit surface 211 adjacent to the light incident surface 210 , and a bottom surface 212 opposite to the light exit surface 211 . The light incident surface 210 and the light output surface 211 are perpendicular to each other.

[0021] The light guide plate 21 is a cuboid. The light incident surface 210 is formed by a corner of the light guide plate 21 being recessed toward the inside of the light guide plate 21 . The light incident surface 210 is an arc surface, and the light incident surface 210 faces away from the incident direction of the incident light beam and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com