Self-arc-extinguishing anti-contamination anti-icing-flashover insulator

A self-extinguishing arc and insulator technology, which is applied in the field of power transmission equipment and insulators, can solve the problems of accumulation of dirt, limited arc extinguishing times, and affecting insulation performance, etc., and achieves the effects of easy installation, low arc extinguishing rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

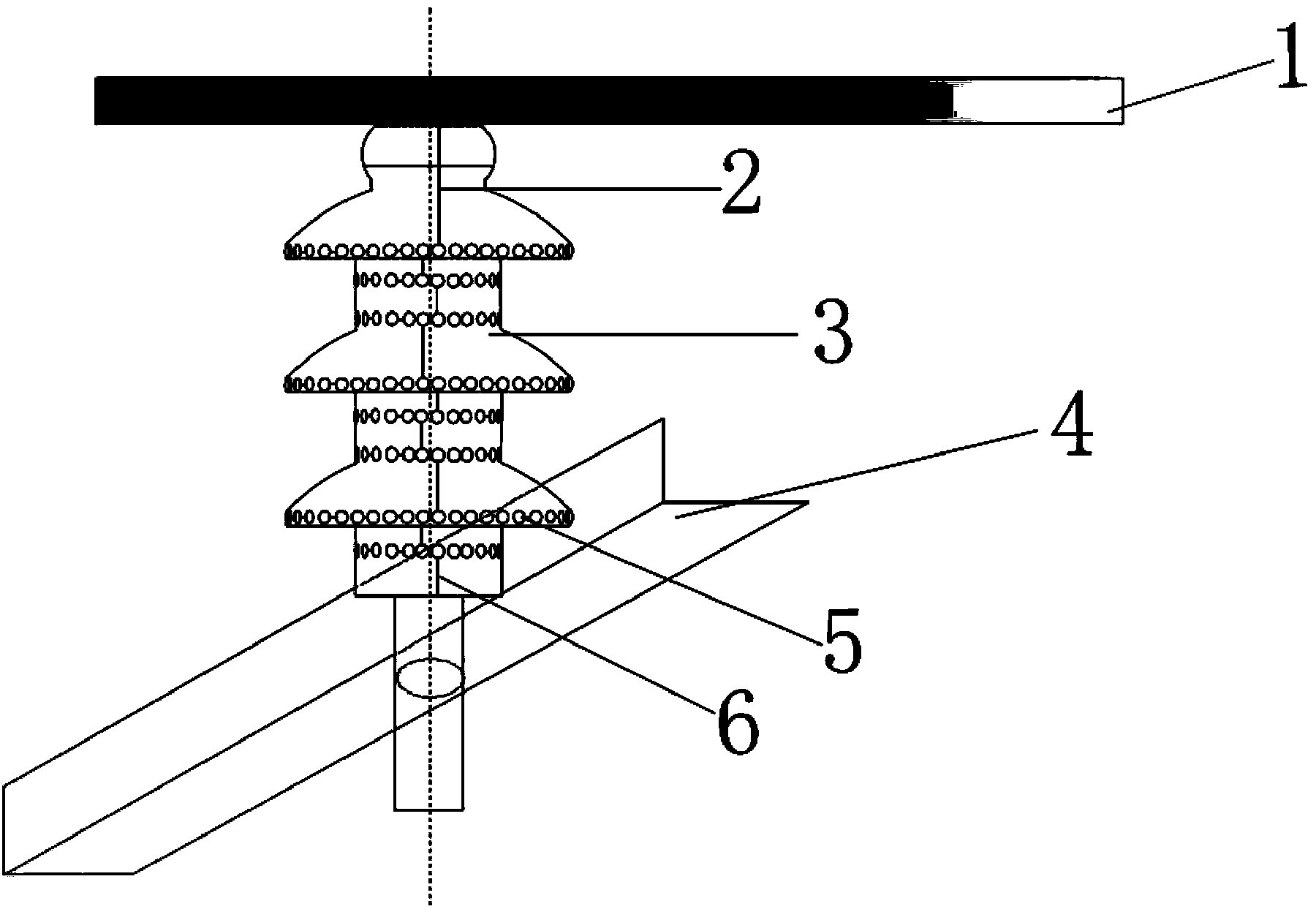

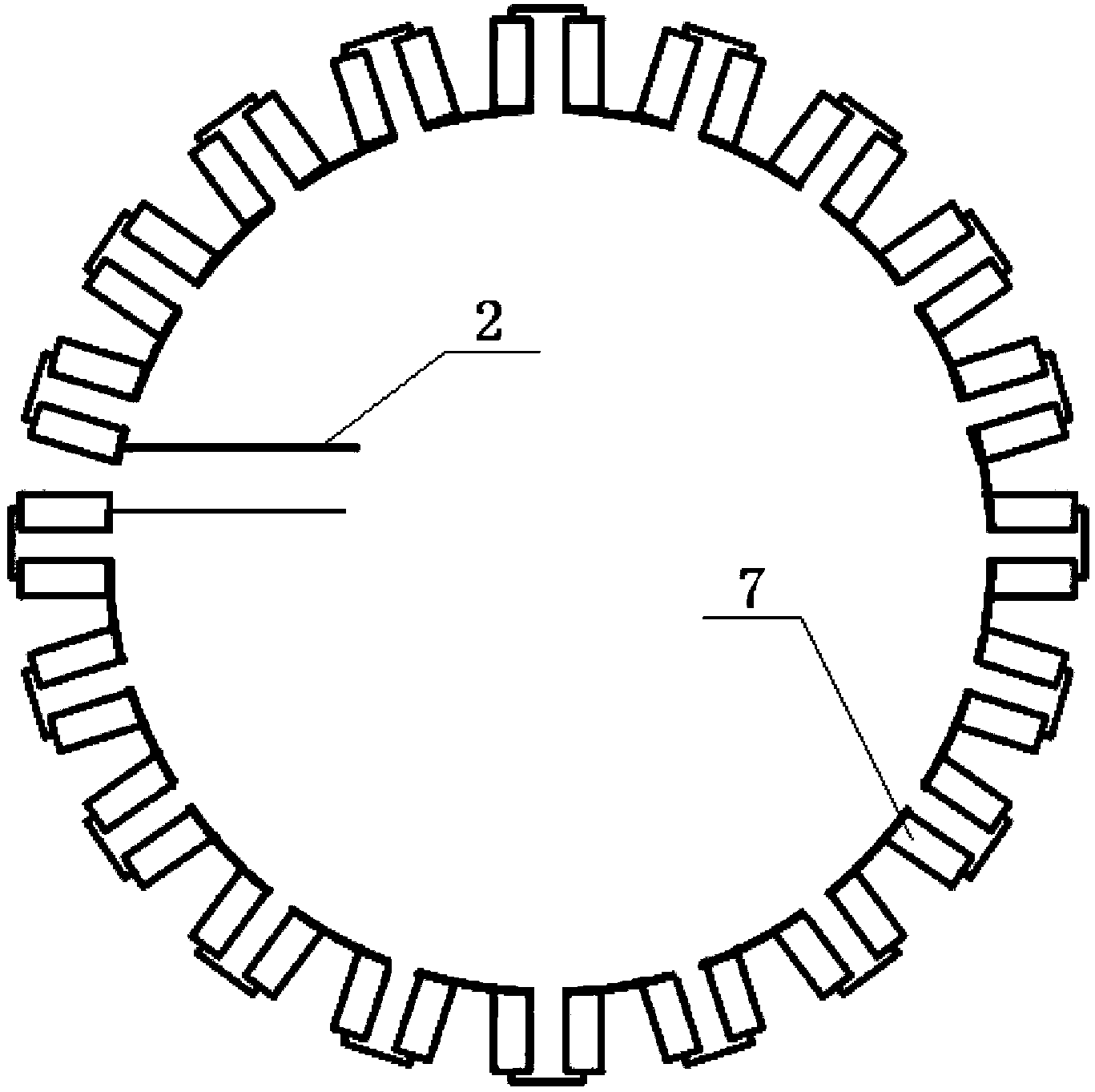

[0034] Such as Figure 1-2 As shown, a self-extinguishing anti-pollution anti-ice flash insulator includes an insulating main body 3 and an arc extinguishing tube 7; one end of the insulating main body 3 is fixedly installed on the cross arm 4, and the other end is fixedly connected to the overhead wire 1; wherein , the insulating main body 3 is provided with several groups of U-shaped arc extinguishing pipes 5; the arc extinguishing pipes 7 are fixedly installed in the arc extinguishing pipes 5, and the ends of the arc extinguishing pipes 7 are connected in series through wires; On the side close to the overhead conductor 1, the head end of the first arc extinguisher 7 in the insulating body 3 is connected to the overhead conductor 1 through the wire I2; The end of the arc extinguishing tube 7 is connected with the cross arm 4 through the wire II6.

[0035] Such as Figure 4 As shown, the arc extinguishing tube 7 is mainly composed of an outer wall ceramic tube 8, a sealing...

Embodiment 2

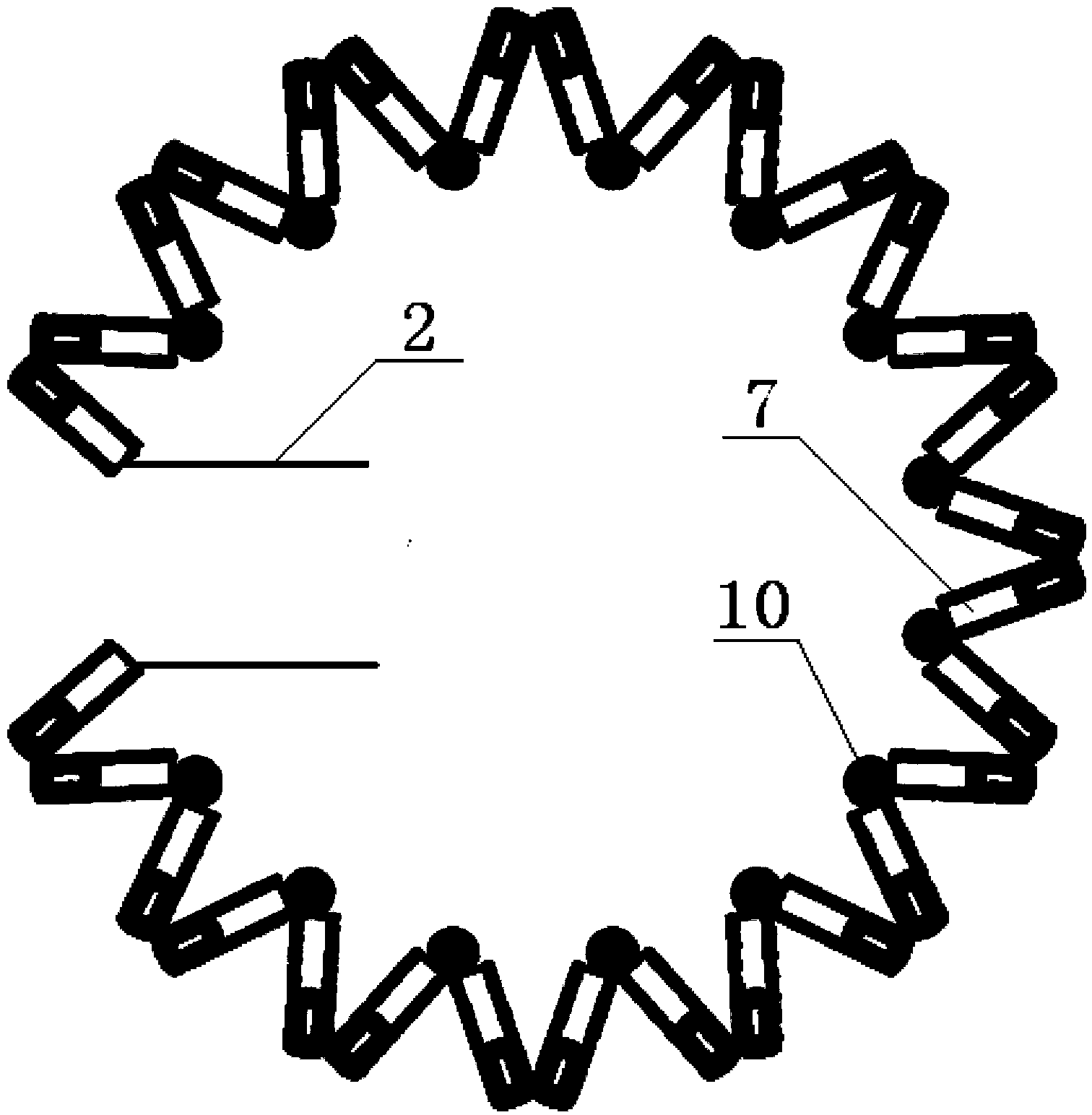

[0039] The difference between this embodiment and Embodiment 1 is that several groups of V-shaped arc extinguishing pipes 5 are arranged inside the insulating main body 3; image 3 As shown, the ends of the arc extinguishing tubes 7 installed in the arc extinguishing tube 5 are in contact with each other to form a reliable connection; and a metal ball 10 is placed where the sealing pieces 11 of the two arc extinguishing tubes 7 contact each other.

Embodiment 3

[0041] The difference between this embodiment and embodiment 1 is: as Figure 6 As shown, the arc extinguishing pipe 5 is spirally arranged in the insulating body 3 from top to bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com