Miniature multi-degree-of-freedom ultrasonic motor

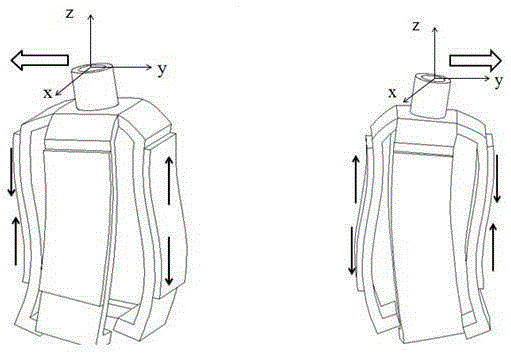

An ultrasonic motor, degree of freedom technology, applied in generators/motors, electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the problem that the transmission mechanism affects the operation accuracy and stability of the system, and the bulky volume , complex mechanism and other problems, to achieve the effect of less parts, small volume and small overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

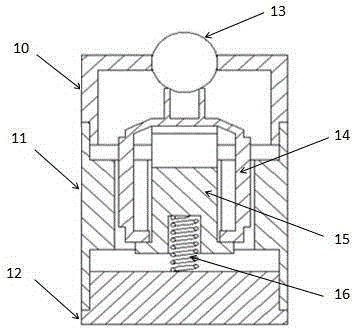

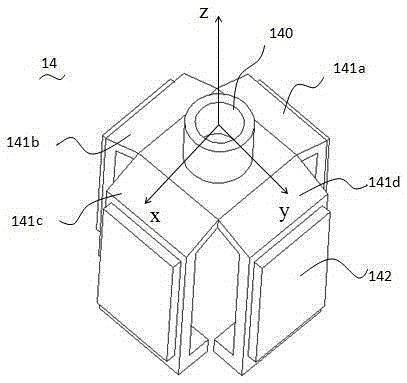

[0020] Such as figure 1 As shown, a miniature multi-degree-of-freedom ultrasonic motor includes a top cover 10, a sleeve 11, a base 12, a rotor 13, a stator 14, a retaining ring 15 and a spring 16; the sleeve 11 is connected to the top cover 10 and the The base 12 is connected, the rotor 13 is in spherical contact with the through hole in the center of the upper surface of the top cover 10, the through hole is coupled with the rotor 13, the diameter of the through hole is smaller than the diameter of the rotor 13, and then the rotor 13 is realized. 13 and the pre-positioning of the vertical direction of the stator 14, the top of the stator 14 is in spherical contact with the rotor 13, the spring 16 is installed in the retaining ring 15, and the lower end is in contact with the base 12, the The retaining ring 15 supports the stator 14 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com