Hall sensor

A Hall sensor and sensor technology, which is applied in the direction of magnetic sensor arrays, instruments, and electric power measurement by using electromagnetic effect devices, can solve the problems of limiting the accuracy of Hall sensors, reduce residual bias voltage, improve accuracy, The effect of reducing the electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

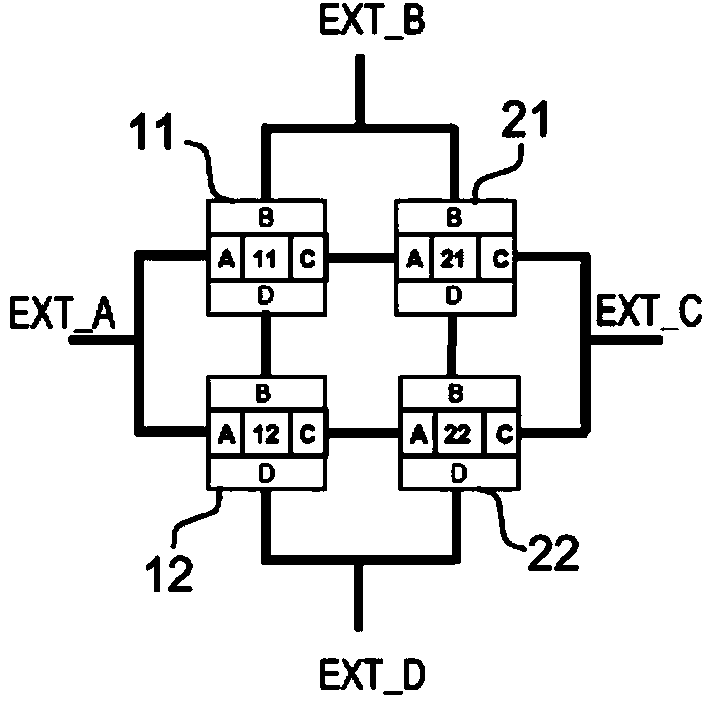

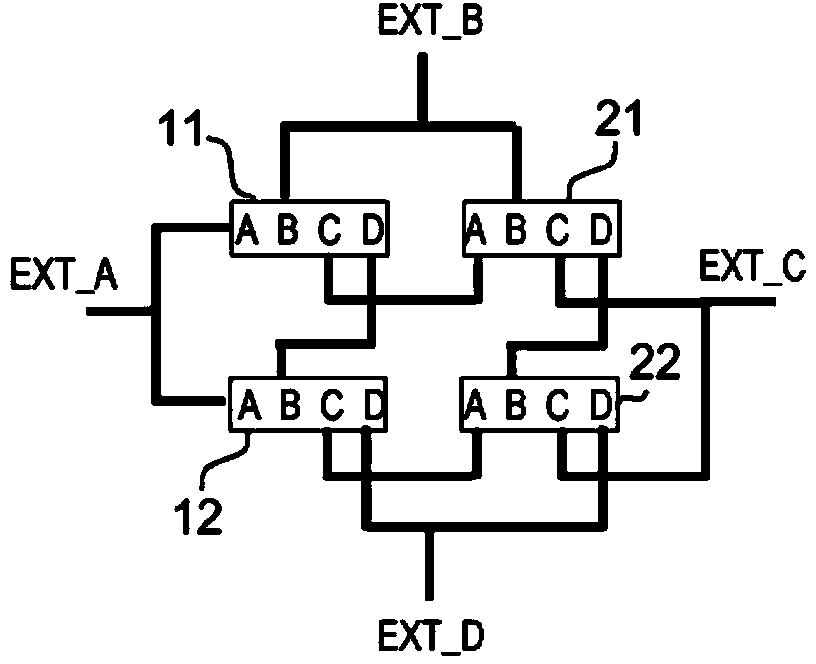

[0084] FIG. 1 shows different embodiments of a Hall sensor with several Hall sensor elements 11 , 12 , 21 , 22 which are interconnected and in this way together form a larger Hall sensor. . Figure 1A An embodiment with a lateral Hall sensor element is shown, while Figure 1B A vertical Hall sensor element is used in the exist Figure 1A with Figure 1B In the two embodiments illustrated in the Hall sensor elements 11, 12, 21, 22 respectively comprise four element terminals or element terminals A, B, C, D, some of which are connected to adjacent Hall sensor element, and some of the element terminals are connected to external terminals or sensor terminals EXT_A, EXT_B, EXT_C, EXT_D. The circuit is implemented similarly in both embodiments, so that the following description of the circuit can be applied to Figure 1A with Figure 1B .

[0085] In the Hall sensor, the element terminals A of the Hall sensor elements 11 , 12 are commonly connected to the sensor terminal EXT_...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com