Frying oil containing capsaicin and method for reducing generation of polymer during frying process

A technology of capsaicin and frying oil, which is applied in the field of oil, can solve the problems of extensive and changing oil formula, and achieve the effect of preventing heart disease, lowering blood pressure and serum cholesterol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

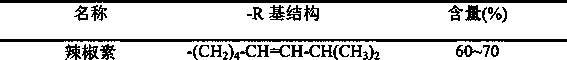

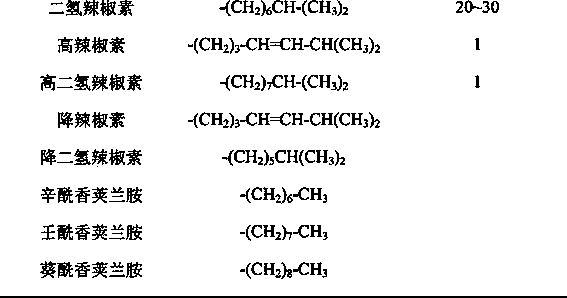

[0124] Embodiment 1: to the investigation of capsaicin addition

[0125] Grease treatment: Weigh 1500g rapeseed oil, heat it to 40~80℃, add a certain amount of capsaicin (CAP) to dissolve evenly in the oil sample.

[0126] Fried chicken wings: Add the prepared oil sample into the pot and heat to 160~220°C.

[0127] Wrap the marinated chicken wings with the prepared coating powder, put 8 chicken wings at a time for frying, fry for 6 minutes and finish the pan. Repeat the above operation and fry 15 times. During the frying process, 200g of samples were reserved for every 5 pots. Take a sample to test the polymer content in the oil.

[0128] Each experimental raw material in comparative example 1 and embodiment 1 is shown in table 2.

[0129] The raw material of table 2 comparative example 1 and embodiment 1

[0130]

[0131]

[0132] The fried oil samples in Comparative Example 1 and Example 1 were tested for polymer content, and the test results are shown in Table 3....

Embodiment 2

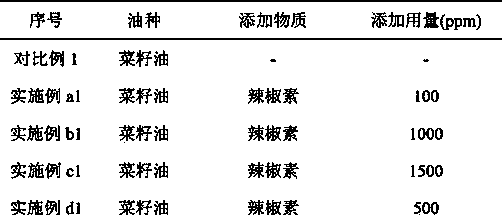

[0140] Embodiment 2: to the investigation of oil kind

[0141] According to the method of Example 1, fry chicken wings according to the raw materials shown in Table 4, and examine the influence of different oil types on the polymer content. The raw materials of each experiment in Comparative Example 2 and Example 2 are shown in Table 4.

[0142] The raw material of table 4 comparative example 2 and embodiment 2

[0143]

[0144] After the oil samples in Comparative Example 2 and Example 2 were fried, the detection results of the polymer content in the oil samples are shown in Table 5.

[0145] The oil sample detection result of table 5 comparative example 2 and embodiment 2

[0146]

[0147] data analysis:

[0148] According to the mensuration of polymer content in the oil sample after frying in table 5, after adding capsaicin in soybean oil, corn oil, palm oil, the content of polymer is all higher than the content of polymer in the oil without adding capsaicin The ...

Embodiment 3

[0152]Weigh 1500g of soybean oil into the pot and heat to 60°C, add 300ppm of capsaicin until the oil sample is evenly dissolved. Put the prepared oil sample into the pot and heat it to 180° C., then fry the chicken wings according to the method described in Example 1, and detect the polymer content in the oil sample.

[0153] The raw material of table 6 comparative example 3 and embodiment 3

[0154]

[0155] After the oil samples in Comparative Example 3 and Example 3 were fried, the detection results of the polymer content in the oil samples are shown in Table 7.

[0156] The oil sample detection result of table 7 comparative example 1 and embodiment 1

[0157]

[0158]

[0159] *: Positive values represent higher polymer content, negative values represent lower polymer content

[0160] data analysis:

[0161] According to the determination of the polymer content in the oil sample after frying in Table 7, it can be known that the content of the polymer in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com