A kind of PU film direct gluing method

A glue-coating and direct technology, applied in the direction of coating, device for coating liquid on the surface, surface pretreatment, etc., can solve the problems of low adhesiveness, lengthening, inability to compound, etc., and achieve the effect of improving the performance of viscose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] PU is the abbreviation of Polyurethane, the Chinese name is polyurethane, referred to as polyurethane, PU is polyurethane, and PU film is polyurethane film. Apparel fabrics, medical and health, leather and other fields. The surface energy of PU material at room temperature is low, and it will become longer under tension. After the temperature rises, it will become softer and will be close to the state of melt flow, so it cannot be coated. The PU film will be stretched and softened when heated. At room temperature, the surface energy of the PU film is very low, and its adhesion to most adhesives is very low, so the traditional direct coating method cannot be used.

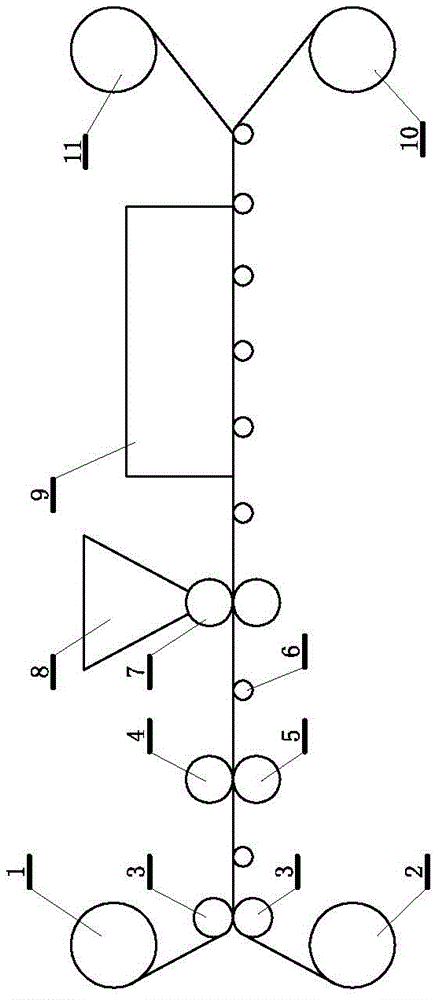

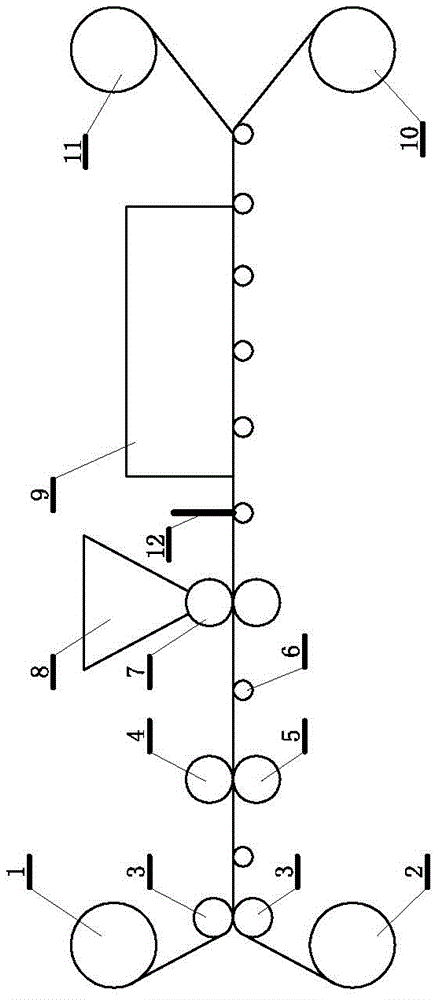

[0016] A kind of PU film direct gluing method, as figure 1 As shown, a PU film roll 1 and a support film roll 2 are released through the guide roller 3, and the support film is attached to the PU film from under the PU film through the upper rubber roller 4 and the lower rubber roller 5, wherein the lower si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com