Printing head and three-dimensional printer

A technology of 3D printer and print head, applied in the direction of processing and manufacturing, manufacturing tools, additive manufacturing, etc., can solve the problems affecting printing quality, affecting the printing of printing nozzles, etc., and achieve the effect of improving printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

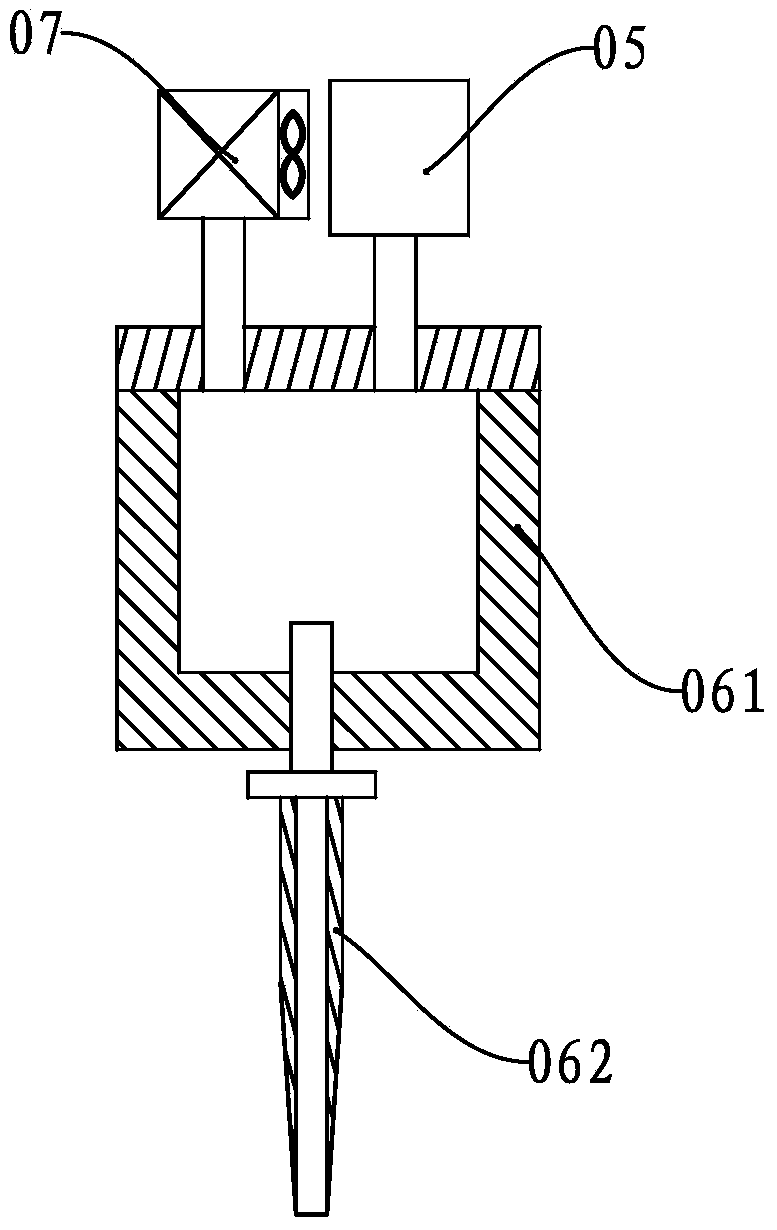

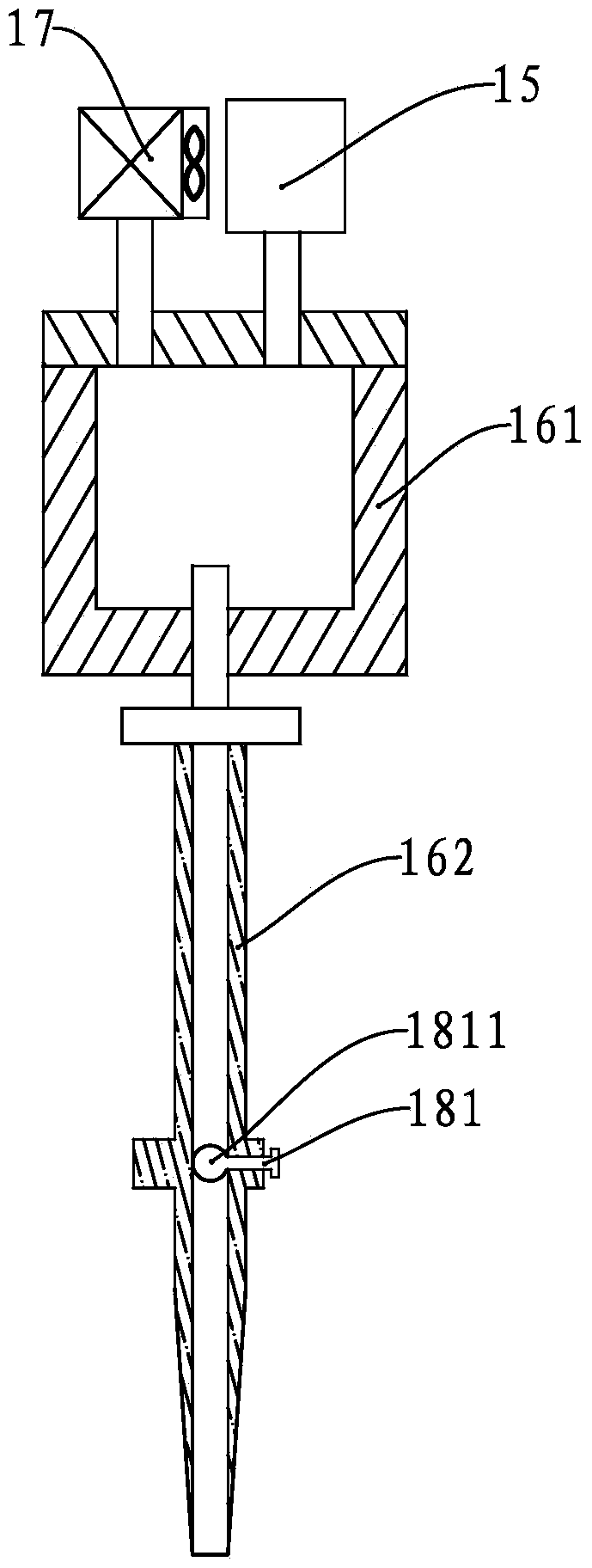

[0036] see Figure 3 to Figure 4, the printing head is made up of feeding device 15, heater 161, cooling device 17, printing nozzle 162 and cut-off valve, and the cut-off valve is the electronic pressure switch 181 that is located in the discharge pipe of printing nozzle 162.

[0037] see image 3 , when the printing nozzle 162 is in the printing state, the controller of the three-dimensional printer controls the electronic pressure switch 181 to drive the end surface of the valve plate 1811 to rotate to be parallel to the axial direction of the printing nozzle 162, and the molding material in the molten state can pass through the outlet of the printing nozzle 162. Tube for printing.

[0038] see Figure 4 , when the printing nozzle 162 is in the stop printing state, the controller of the three-dimensional printer controls the electronic pressure switch 181 to drive the end face of the valve plate 1811 to rotate to be perpendicular to the axial direction of the printing nozz...

no. 2 example

[0040] As a description of the second embodiment of the print head of the present invention, only the differences from the first embodiment of the print head described above will be described below, wherein a mechanical pressure switch is used instead of an electronic pressure switch. When the printing nozzle is in the printing state, when the pressure at the mechanical pressure switch increases and reaches a predetermined value, the mechanical pressure switch is turned on, and the molding material in the molten state can pass through the discharge pipe of the printing nozzle; when the printing nozzle is in the stop printing state , when the pressure at the mechanical pressure switch drops below a predetermined value, the mechanical pressure switch is turned off, cutting off the channel between the inlet and outlet of the printing nozzle.

no. 3 example

[0042] As a description of the third embodiment of the print head of the present invention, only the differences from the first embodiment of the print head described above will be described below. A pressure sensor is provided in the discharge pipe of the print nozzle. When the pressure sensor detects that the print nozzle When the internal pressure reaches a predetermined value, the controller of the 3D printer controls the pressure switch to turn on; when the sensor detects that the pressure in the printing nozzle drops below the predetermined value, the controller of the 3D printer controls the pressure switch to turn off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com