Manual or semi-automatic table three-dimensional adjustment device

A technology of three-dimensional adjustment and workbench, which is applied in the direction of rotary printing machine, printing machine, printing machine, etc. It can solve the problems of high size requirements and shape and position tolerances, which affect the completion of printing operations and printing accuracy, and the difficulty of ensuring the accuracy of sliding blocks, etc. , to achieve the effect of simple and compact mechanical structure design, increase market share, and low requirements for processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

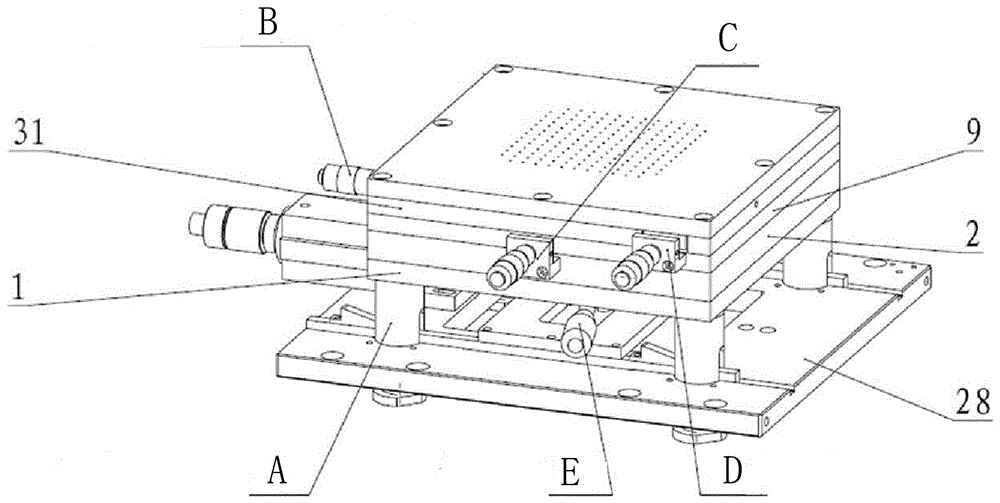

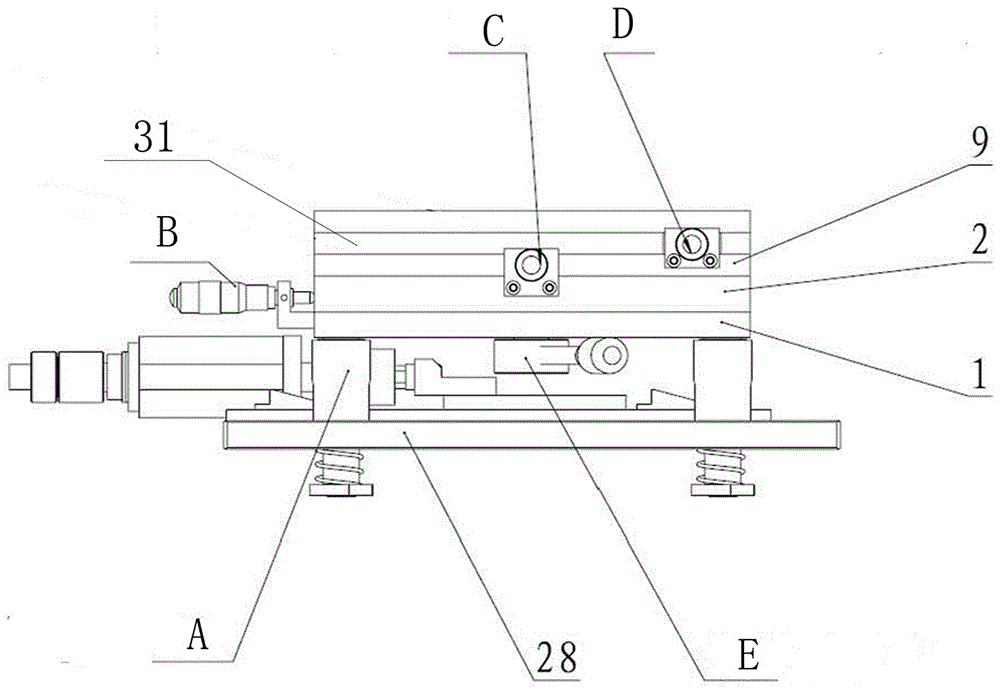

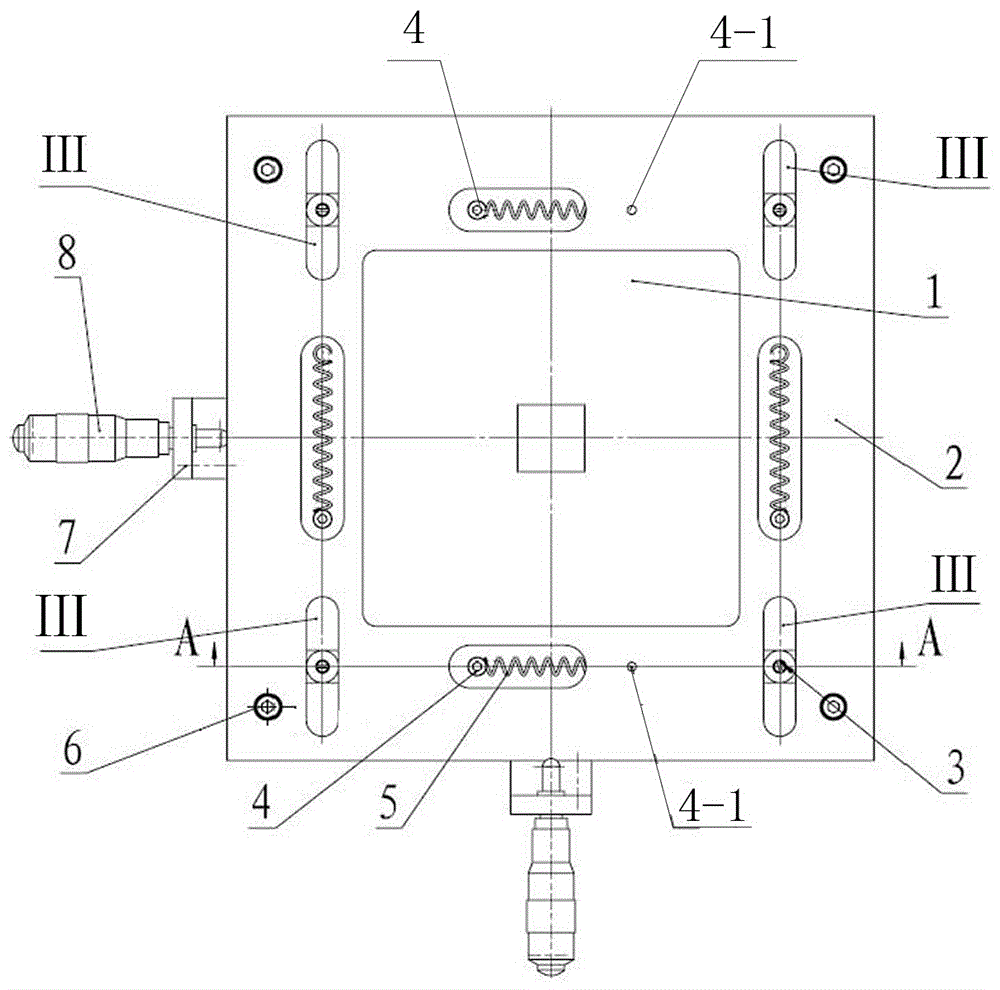

[0037] Such as figure 1 , figure 2 As shown, the manual or semi-automatic workbench three-dimensional adjusting device of the present invention is a kind of brand-new design structure. The manual or semi-automatic workbench three-dimensional adjustment device of the present invention consists of five parts: Z-direction adjustment mechanism A, X-direction adjustment mechanism B, Y-direction adjustment mechanism C, θ angle adjustment mechanism D and locking mechanism E. Among them, the Z-direction adjustment mechanism A is at the bottom of the three-dimensional adjustment device of the manual or semi-automatic workbench, and the Z-direction adjustment mechanism A, the X-direction adjustment mechanism B, the Y-direction adjustment mechanism C, and the θ angle adjustment mechanism D are mutually restricted and connected layer by layer. . The locking mechanism E is located at the center of the plane common to the Z-direction adjustment mechanism C, X-direction adjustment mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com