Volute-type gas-liquid separation device

A gas-liquid separation device, vortex screw technology, applied in the direction of centrifugal separation of water/sewage treatment, degassed water/sewage treatment, etc. problems, to achieve the effect of convenient and simple gas-liquid separation, prolonging service life and improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

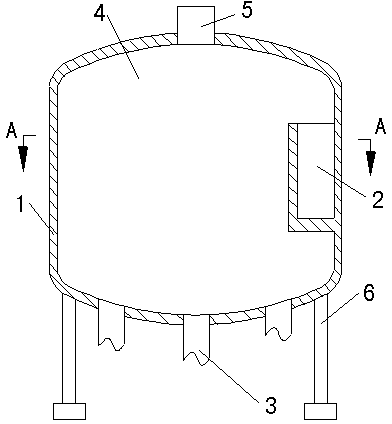

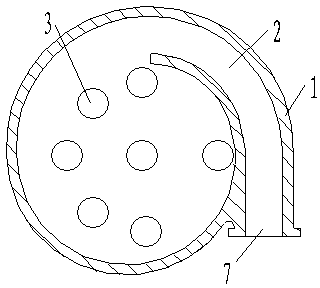

[0014] like figure 1 and figure 2 As shown, the scroll type gas-liquid separation device of the present invention is provided with a spiral channel 2 inside the volute 1, and a liquid inlet 7 is provided outside the spiral channel 2. Above the spiral passage 2 is an air chamber 4 . The bottom of the volute 1 is provided with a return port 3 . The top of the volute 1 is provided with an exhaust port 5 . The volute 1 is fixed on the bracket 6 . For the convenience of observation, an observation window can be provided on the volute 1.

[0015] When the above-mentioned device is applied, the gas-lifting tube in the anaerobic or aerobic reactor is connected to the liquid inlet 7, and the gas-liquid discharged from the gas-lifting tube spirally flows in the spiral channel 2, and the bubbles are released in a large amount instantly, which improves the gas The liquid separation effect and efficiency avoid the "breathing" phenomenon during gas-liquid separation, and will not caus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com