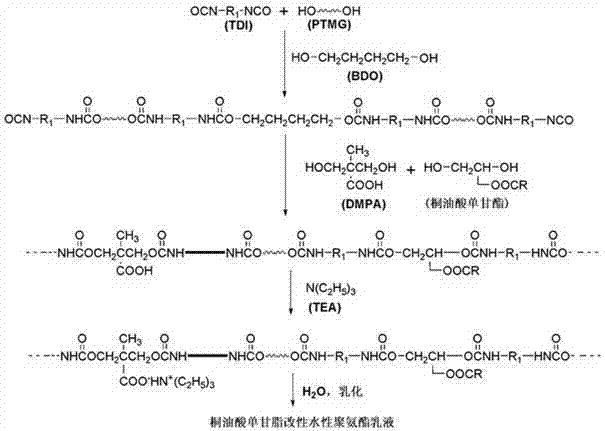

Preparation method of eleostearic acid monoglyceride modified waterborne polyurethane emulsion

A technology of water-based polyurethane and tung oleic acid, applied in the field of chemical synthesis, can solve the problems such as failure to achieve modification, complicated operation, long reaction time, etc., and achieve the effect of increasing the degree of cross-linking and improving the poor water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0024] Add 10 g of polytetrahydrofuran glycol (PTMG) into the reactor, and vacuum dehydrate at 110 °C for 1 h. 27.7 g of acetone was added, and 6.0 g of toluene 2,4-diisocyanate (TDI) was added dropwise at 60° C. to react for 1 h. Add 1 drop of catalyst dibutyltin dilaurate (DBTDL), dropwise a mixture of 1.1 g dimethylolpropionic acid (DMPA), 0.3 g 1,4-butanediol (BDO) and 1.8 g oleic acid monoglyceride, React for 4 h. After cooling down to 40°C, 0.8 g of triethylamine was added and reacted for 20 min. After cooling down to 40°C, 27.4 g of deionized water was added under high-speed stirring, emulsified and dispersed for 30 min, and then the acetone was removed under reduced pressure to obtain oleic acid monoglyceride modified water-based polyurethane emulsion.

Embodiment example 2

[0026] Add 10 g of polyoxypropylene glycol (PPG) into the reactor, and vacuum dehydrate at 110 °C for 1 h. 23.4 g of acetone was added, and 7.4 g of isophorone diisocyanate (IPDI) was added dropwise at 60°C for 1 h of reaction. Add 1 drop of catalyst dibutyltin dilaurate (DBTDL), dropwise add a mixture of 1.7 g dimethylolbutyric acid (DMBA), 0.1 g diethylene glycol (DEG) and 1.3 g oleic acid monoglyceride, and react 4 h. After cooling down to 40°C, 1.1 g of triethylamine was added and reacted for 20 min. After cooling down to 40°C, add 25.9 g of deionized water under high-speed stirring, emulsify and disperse for 30 min, and remove the acetone under reduced pressure to obtain oleic acid monoglyceride modified water-based polyurethane emulsion.

Embodiment example 3

[0028] Add 10 g of polycarbonate diol (PCDL) into the reactor, and vacuum dehydrate at 110 °C for 1 h. 25.9 g of acetone was added, and 5.0 g of hexamethylene diisocyanate (HDI) was added dropwise at 60°C for 1 h of reaction. Add 1 drop of catalyst dibutyltin dilaurate (DBTDL), dropwise add a mixture of 1.3 g dimethylolacetic acid, 0.1 g ethylene glycol (EG) and 1.0 g oleic acid monoglyceride, and react for 4 h. After cooling down to 40°C, 1.3 g of triethylamine was added and reacted for 20 min. After cooling down to 40°C, add 25.9 g of deionized water under high-speed stirring, emulsify and disperse for 30 min, and remove the acetone under reduced pressure to obtain oleic acid monoglyceride modified water-based polyurethane emulsion.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap