ALD equipment and reaction source diffusion distribution detection and control method applied to ald equipment

A control method and reaction source technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problem that ALD equipment cannot accurately measure the diffusion distribution of reaction sources, and cannot well control the interaction of different reaction sources. The effect of isolation and other issues can be achieved to save process time and improve speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

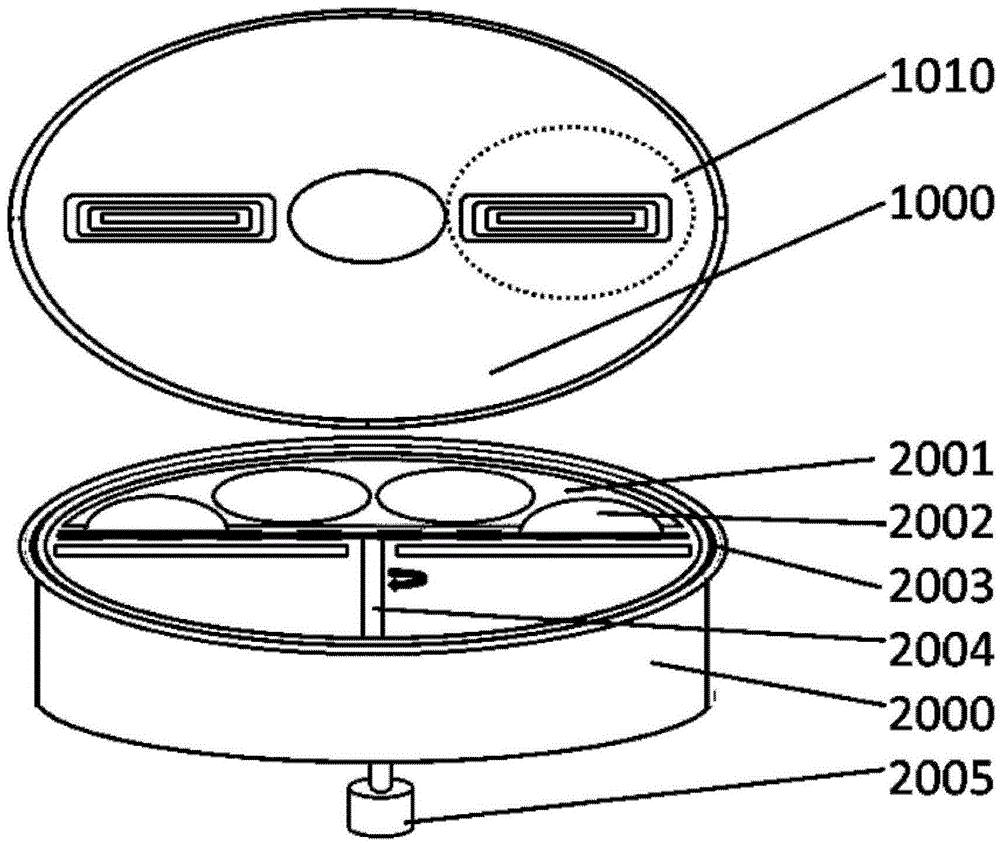

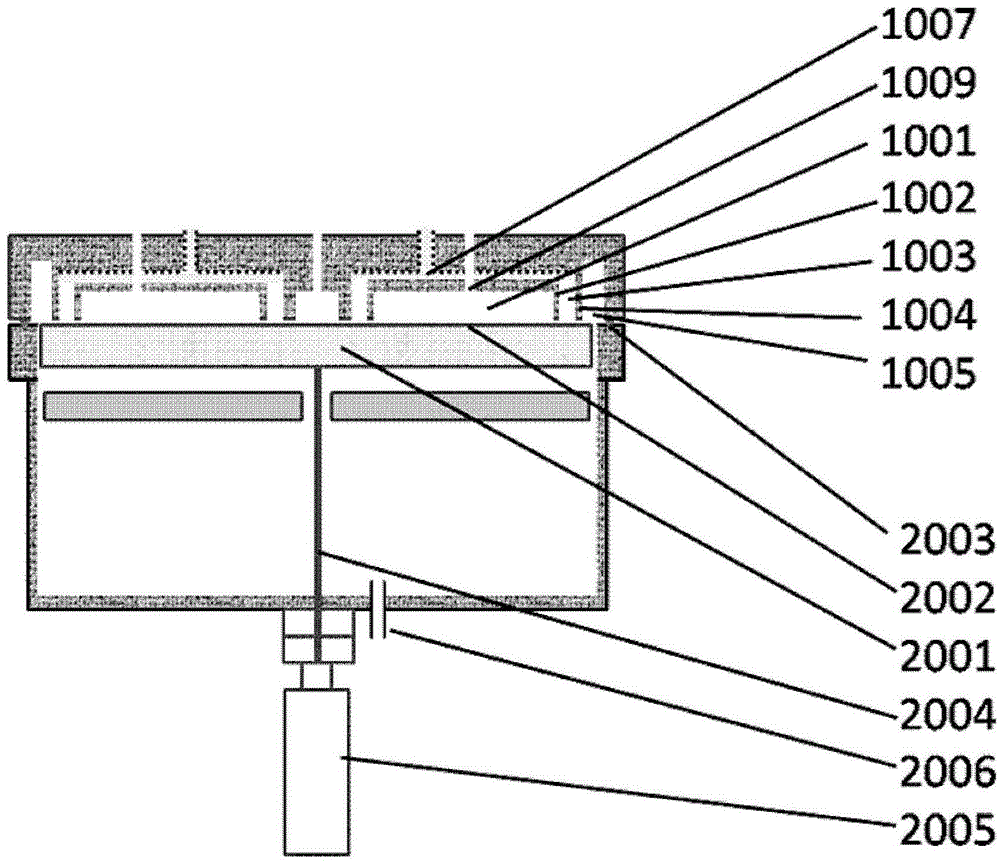

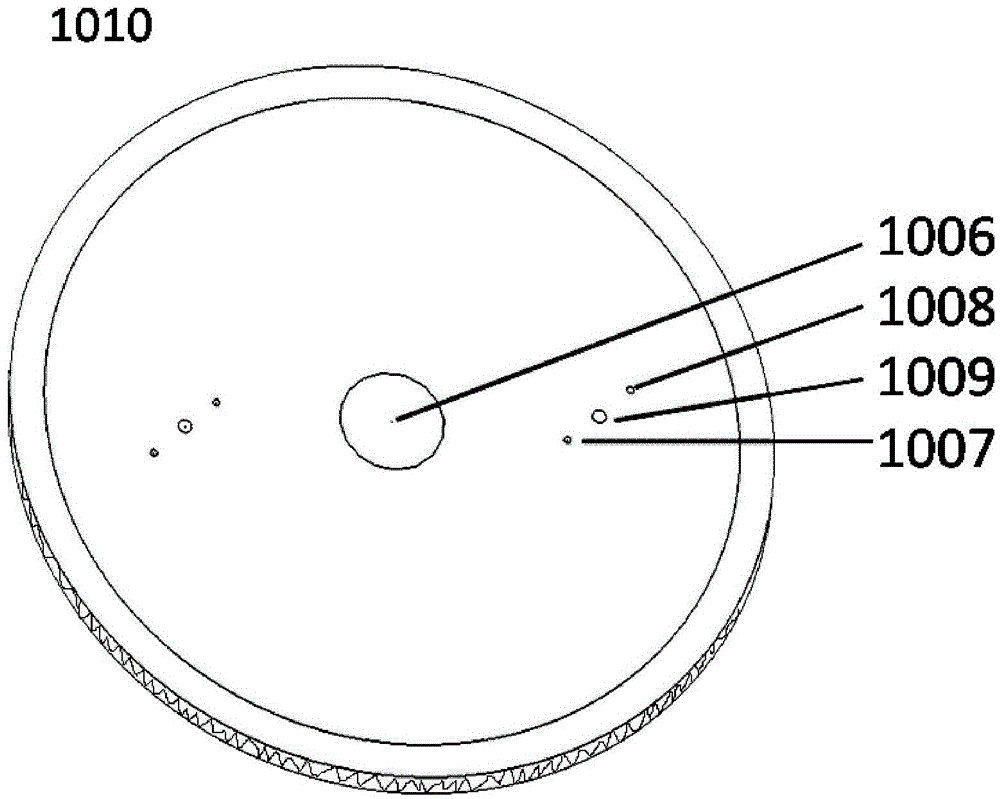

[0032] The ALD device of the present invention is an openable and closable cavity, including a cover plate and a main body chamber matched with the cover plate. There is a carrier tray in the main chamber, which is used to carry components that need to be subjected to an ALD process. At least two gas path unit groups are arranged on the inner surface of the cover plate, each gas path unit group includes at least one gas path unit, and each gas path unit is used for passing gas when the ALD equipment is closed, and passing the gas The gas is confined in the area between the lower part of the gas circuit unit and the carrier plate. When the cover plate is closed with the main body chamber, there is no contact between each air circuit unit and the carrying plate, that is, there is a gap for air flow to pass through. Each of the at least two gas circuit unit groups is used to feed different reaction source gases.

[0033] Each of the air path units includes a plurality of airflo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com