Method for assembling upper and lower seal heads of nuclear power containment and jig frame structure

An assembly method and containment technology, which is applied to arch structures, dome structures, building components, etc., can solve the problems of complex structures and high costs, and achieve the effect of simple and efficient pillar support structures, saving time and economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

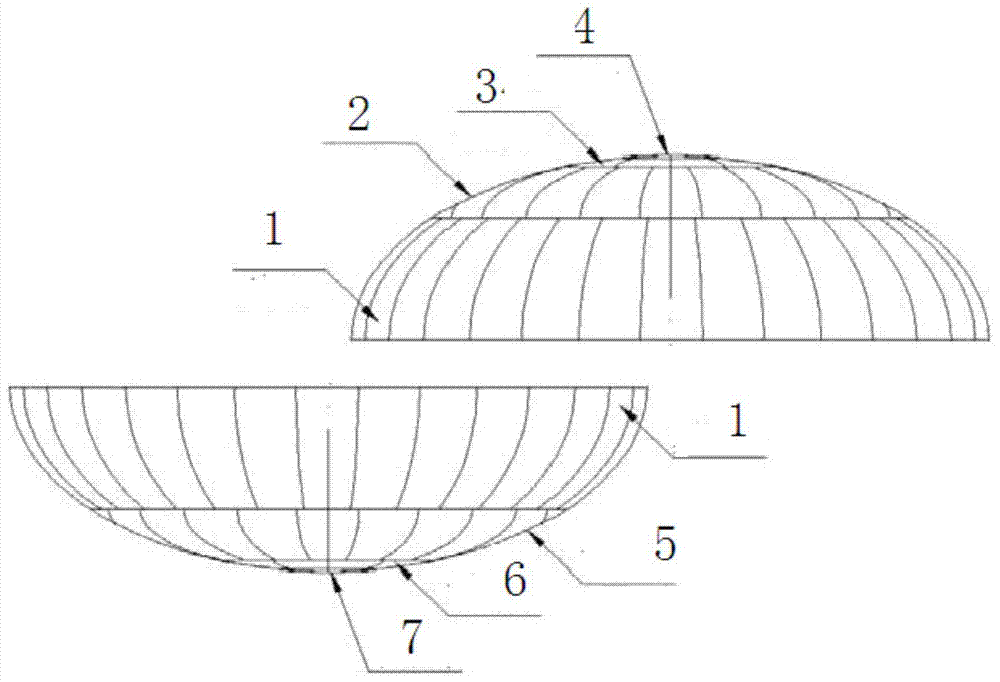

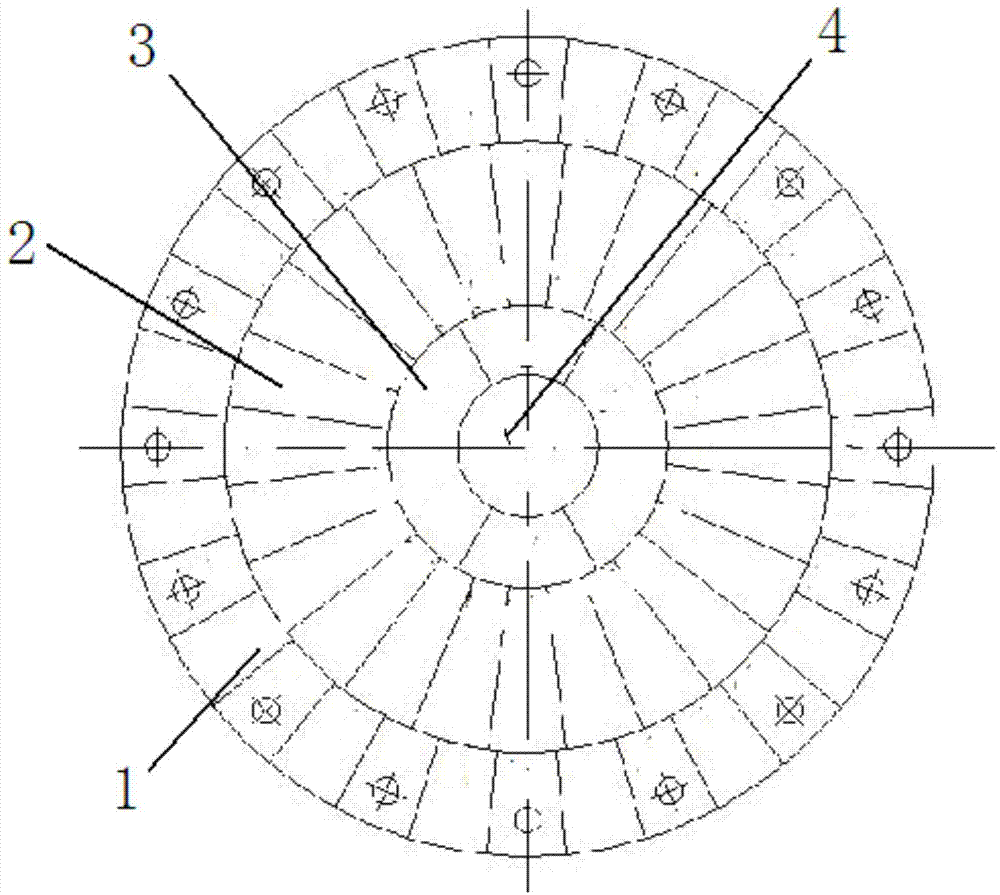

[0036] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, the shell can be divided into the following parts: the upper head is the equatorial zone, the upper temperate zone, the upper frigid zone, and the upper polar zone; the lower head is the equatorial zone, the lower temperate zone, the lower frigid zone, and the lower polar zone; figure 2 Each band consists of a different number of shells, as shown;

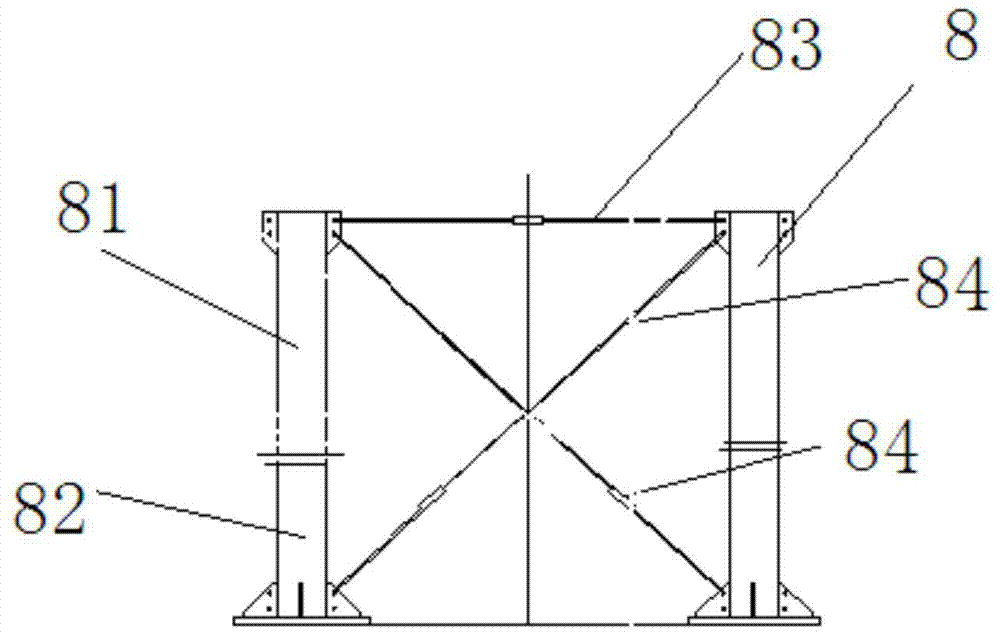

[0037] Such as image 3 and Figure 4 As shown, the tire frame structure includes a ring-shaped lower pillar supporting structure and a central pillar arranged at the center of the ring. The lower pillar supporting structure includes a horizontal tie rod, a diagonal tie rod, and a supporting pillar. The supporting pillar is composed of a lower pillar, an upper pillar Composition; the lower pillar is a hydraulic lifting structure, the tie rod is connected to two adjacent support pillars, and the diagonal ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com