Structure for preventing backflow from entering air intake duct of air-breathing pulse detonation engine

A technology of pulse detonation and air intake structure, which is applied to machines/engines, rocket engine devices, jet propulsion devices, etc. The effect of reducing pressure pulsation and improving propulsion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

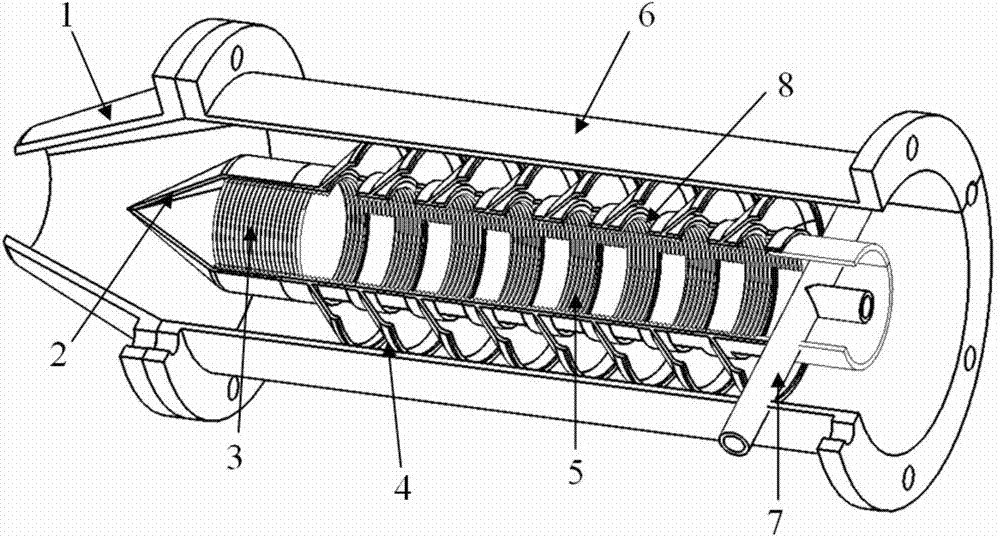

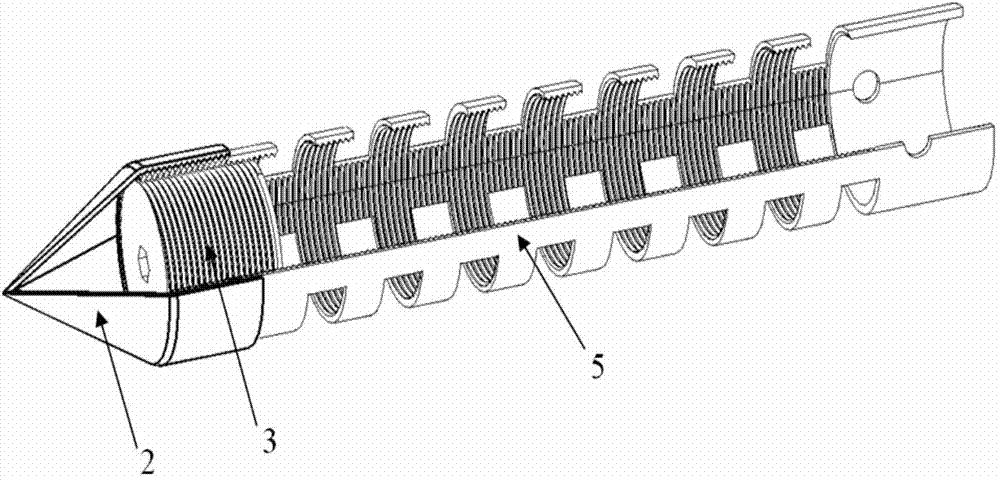

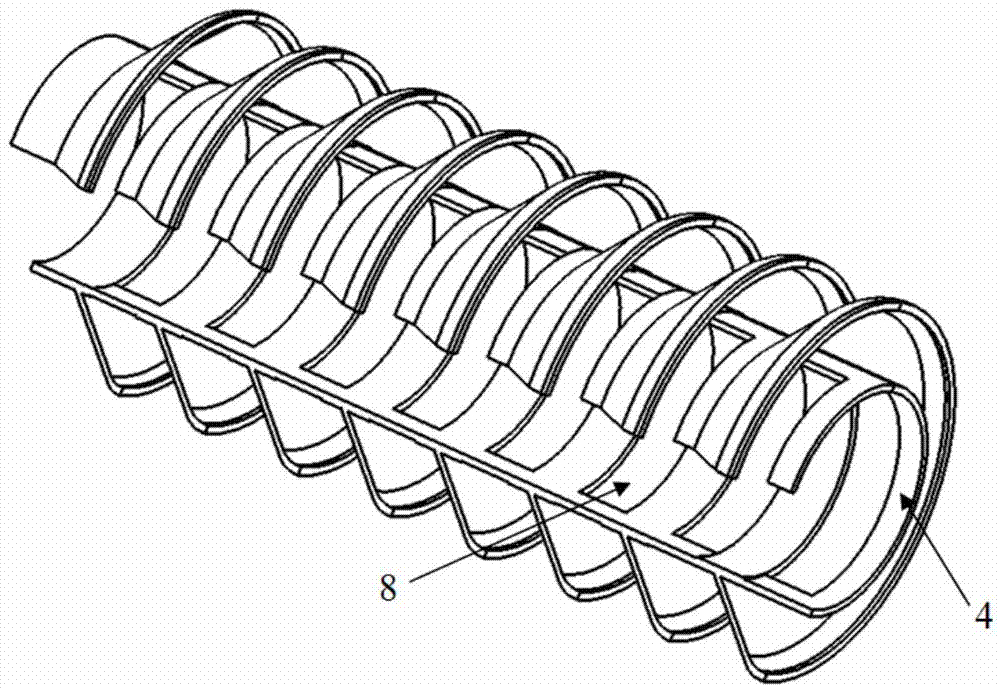

[0020] Such as Figure 4 As shown, the inner wall surface of the cylinder 5 of the anti-reflux intake structure of the air-breathing pulse detonation engine in this embodiment is processed with internal threads, and the adjustable inner plug 3 is installed in the cylinder 5 through threaded connection, and can be adjusted by The hexagonal hole at the end of the inner plug 3 adjusts the position of the plug in the cylinder 5. During the air intake process, the air enters the detonation chamber 11 through the air intake channel and the annular channel. Fuel is sprayed axially into the detonation chamber 11 through the fuel pipe 7 and mixed with air. After the igniter 10 is ignited and detonated, the backflow enters the cavity of the cylinder 5 against the direction of the incoming flow, and enters the annular cavity of the circular tube section 6 from the two rows of annular backflow grooves 8 in the inner cavity. The cylinder 4 guides the air flow, the direction of the revers...

Embodiment 2

[0022] Such as Figure 5 As shown, Venturi 9 is installed between the circular pipe section 6 of the anti-backflow air intake structure of the air-breathing pulse detonation engine of this embodiment and the connecting section of the detonation chamber 11, and the cross-sectional area of its throat is the same as that of the cylinder 5 inner cavity. equal in cross-sectional area. First, the incoming flow at a certain speed enters the engine from the air inlet formed by the air intake housing 1 and the rectified air intake cone 2, enters the detonation chamber 11 after passing through the ring cavity formed by the guide fin cylinder 4 and the cylinder 5, and It is fully mixed and atomized with the fuel sprayed from the fuel pipe 7. When the detonation chamber 11 is filled, the igniter 10 starts to ignite, forming a slow wave that propagates to the outlet of the detonation chamber, and the slow wave is accelerated by the spiral intensifier 12 to form a detonation wave that pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com