Prefabricated concrete barrel section, manufacturing method of prefabricated concrete barrel section and wind generating set tower barrel

A technology of precast concrete and manufacturing method, which is applied in the directions of wind turbines, final product manufacturing, wind turbine components, etc., can solve the problems of reducing the overall strength of the tower, reducing the strength of the tube section, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The precast concrete barrel section of the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

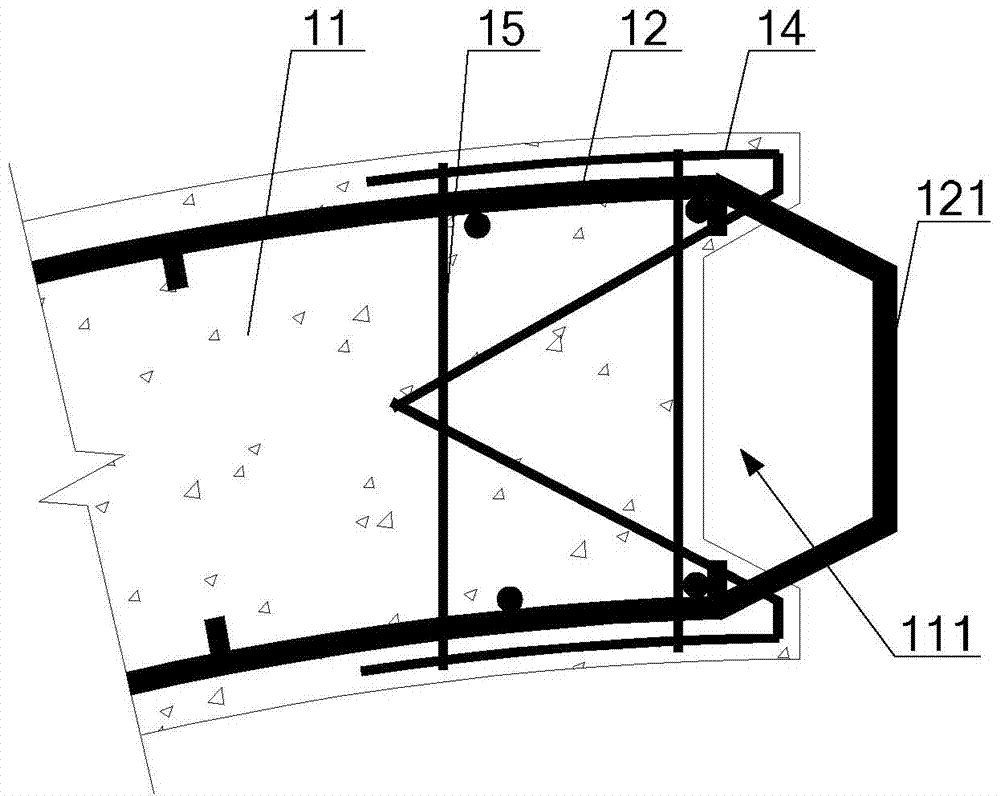

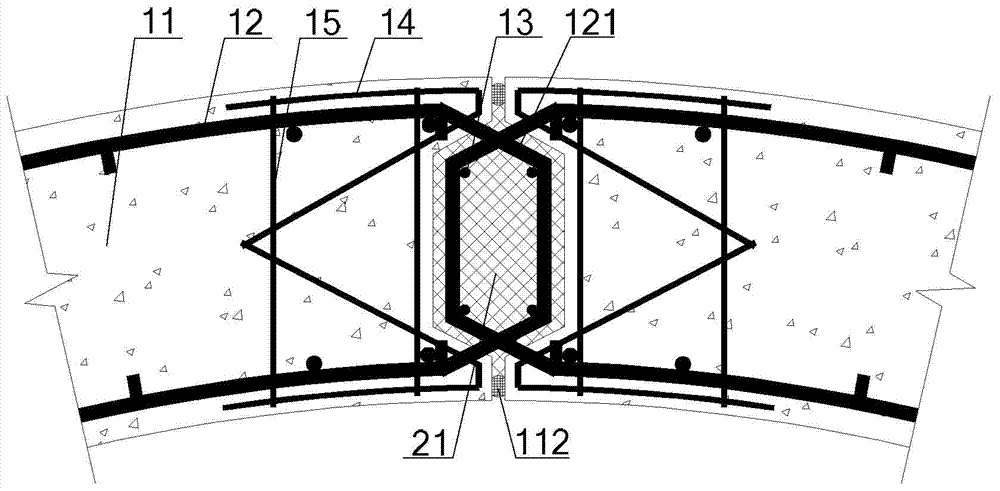

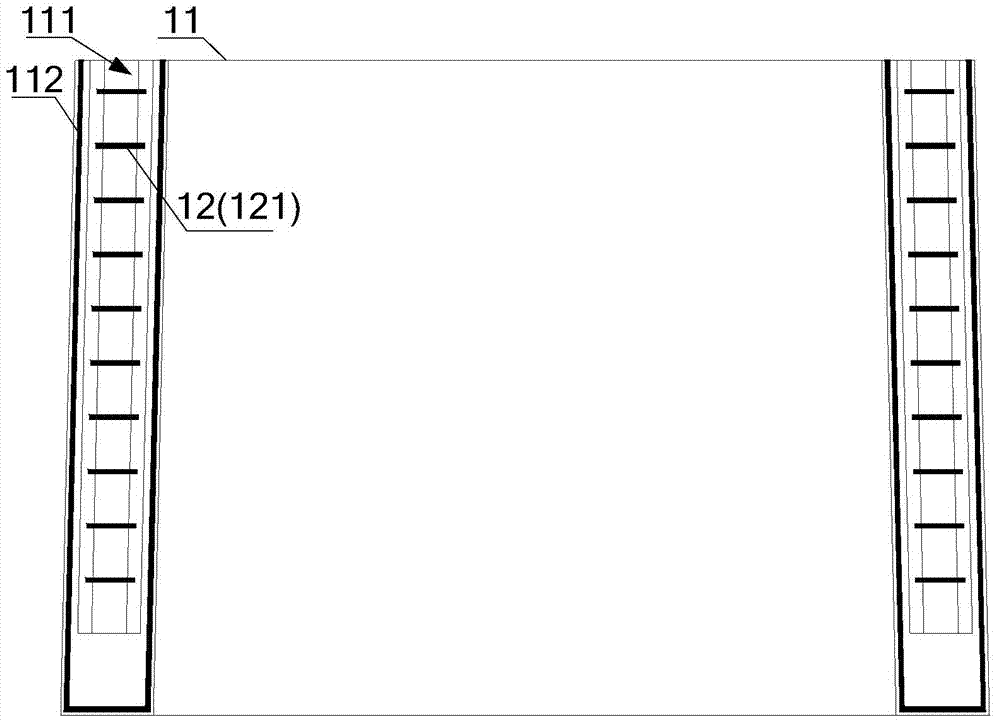

[0030] An embodiment of the present invention provides a prefabricated concrete barrel section, such as figure 1 and figure 2 As shown, it includes at least two arc-shaped members 11 that are mated and connected; along the extension direction of the cylinder section, a plurality of closed-loop reinforcing bars 12 arranged at intervals are arranged inside the arc-shaped member 11; each closed-loop reinforcing bar 12 is arranged along the circumferential direction of the cylinder section, And it includes an extension end 121 located outside the arc-shaped member 11; along the circumferential direction of the barrel section, the end surface of the arc-shaped member 11 is provided with a groove 111, and the groove 11 extends along the extension direction of the barrel section, and is open at the top and bottom. End...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com