A high-power hydraulically driven fracturing pump

A high-power, fracturing pump technology, applied in the direction of pumps, piston pumps, machines/engines, etc., can solve problems such as fatigue damage, speed up fracturing pumps, and reduce service life of fracturing pumps, so as to increase service life and increase total discharge The effect of reducing the amount and manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

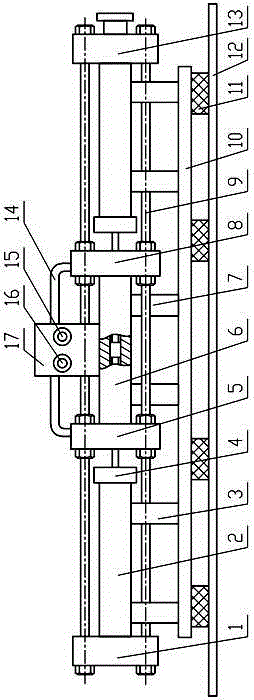

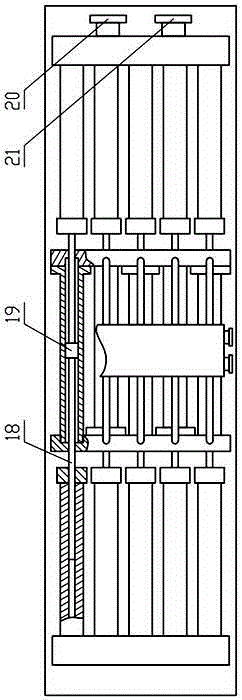

[0011] The present invention is not limited by the following implementation examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions. Combine below figure 1 , figure 2 The present invention is described as follows:

[0012] Such as figure 1 , figure 2 As shown, valve box B5 and valve box C8 are installed at both ends of oil cylinder 6. One end of oil cylinder 6 is connected by thread, and the other end is connected by bolt. Valve box B5 and valve box C8 are used alternately by threaded connection and bolted connection. Make the layout of oil cylinder 6 more compact. The valve box A1 is arranged on the side close to the valve box B5, the valve box A1 is threadedly connected with the pump cylinder 2, and the end of the pump cylinder 2 is connected with the end cover 4 by bolts. The valve box D13 is arranged on the side close to the valve box C8, and the valve box D13 is threadedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com