Radial guide blade of residual heat removal pump

A technology for removing waste heat from pumps and guide vanes, which is applied to the components, pumps, and pump elements of a pumping device for elastic fluids, can solve problems such as the inability to effectively overcome the hydraulic loss of guide vanes, and improve reliability and safety. , improve the force, improve the effect of the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

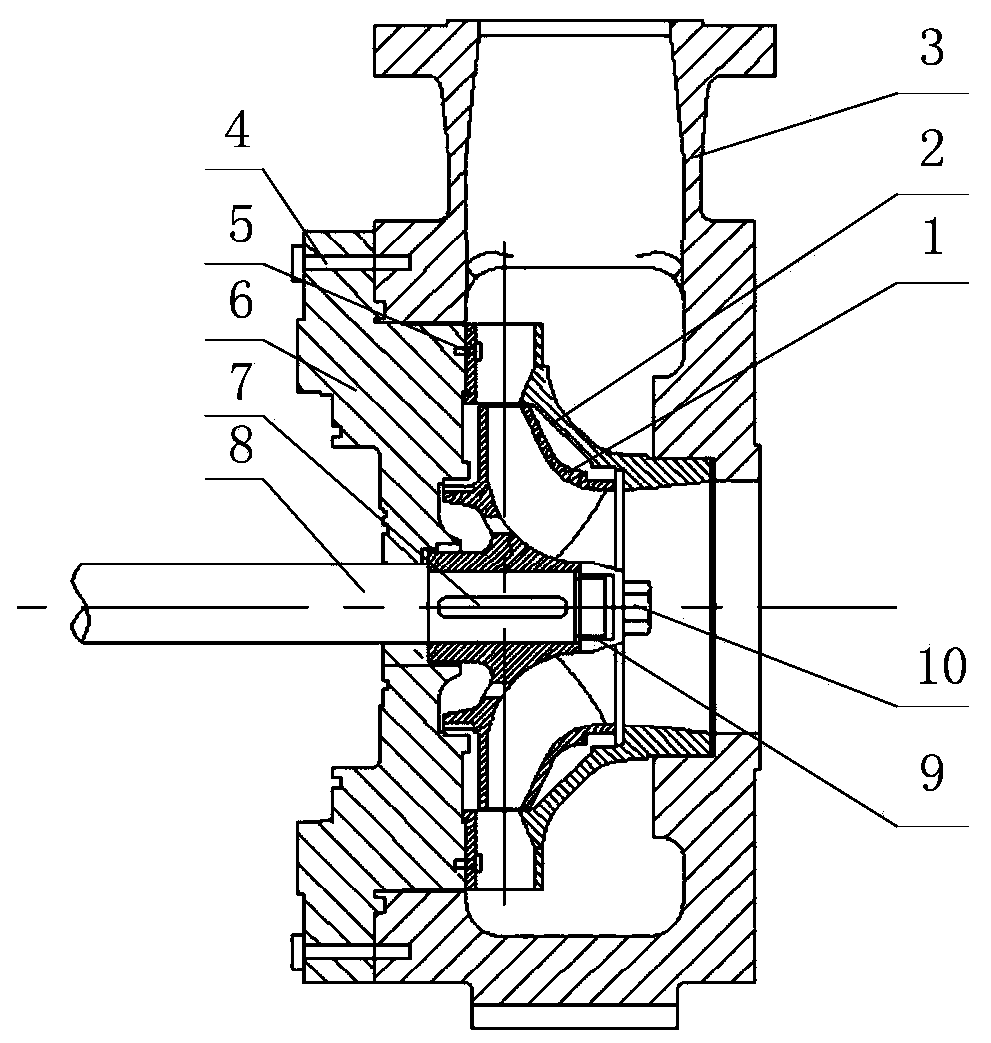

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

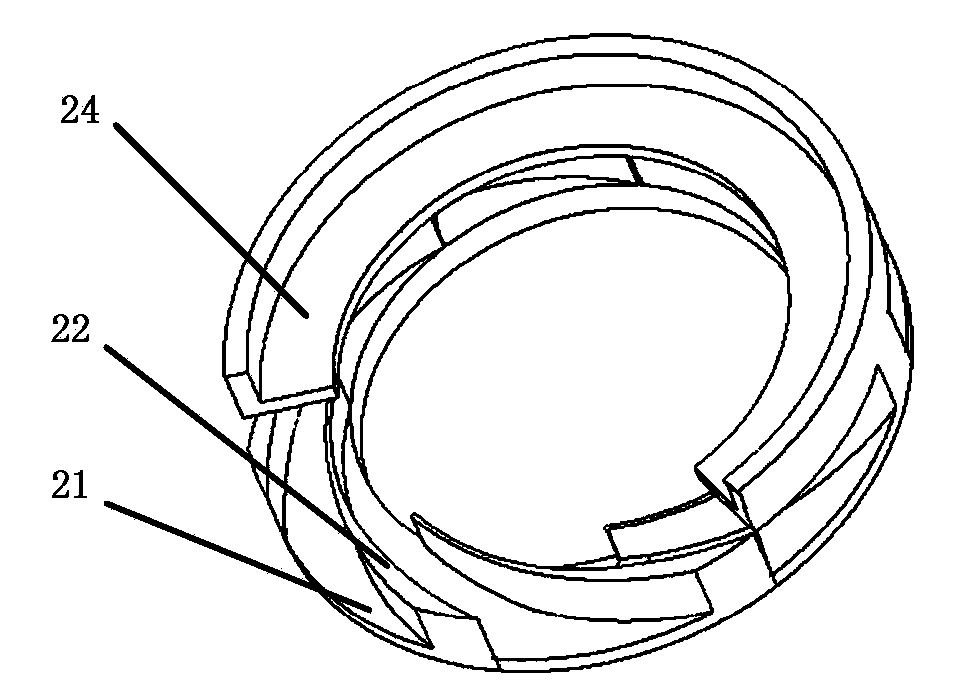

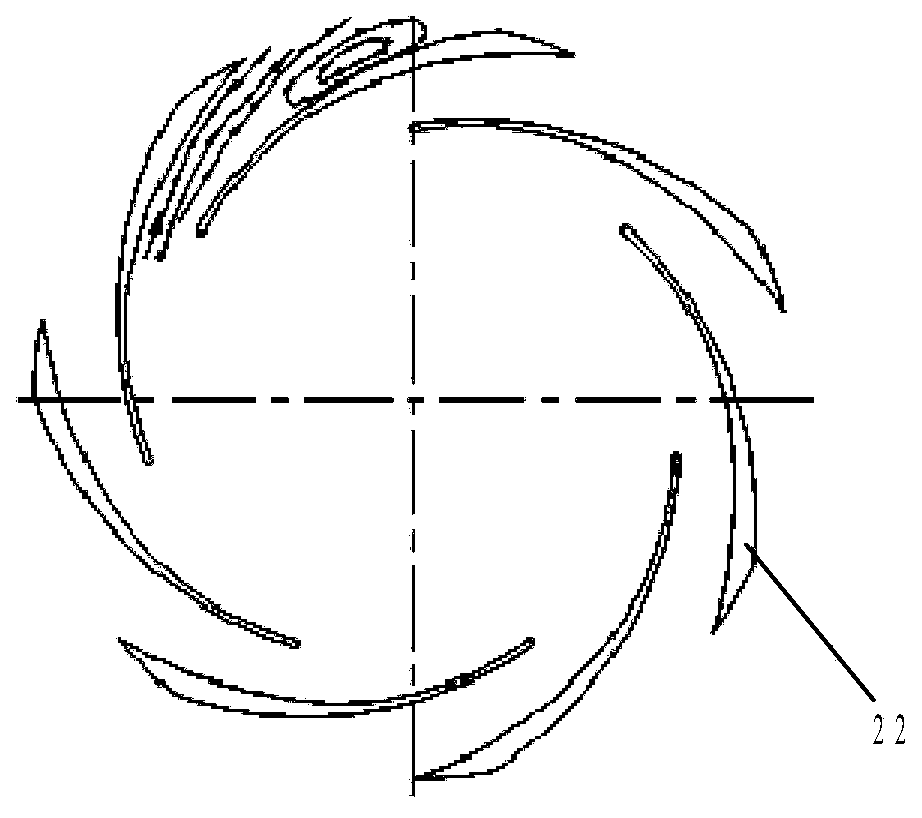

[0025] Figure 4 Shown is a schematic structural diagram of the radial guide vane 2 of the waste heat discharge pump of the present invention, the radial guide vane 2 of the waste heat discharge pump includes a front cover plate 24, a rear cover plate 21, and a plurality of main blades 22 , the front cover plate 24 and the rear cover plate 21 are respectively fixed on the two ends of a plurality of main blades 22 uniformly distributed in the circumferential direction to form an annular pressurized water chamber. Between two adjacent main blades 22, a splitter vane 23 with a splitting effect is arranged, and the inlet diameter D of the splitter vane 23 is 0 =0.6~0.68 (D 3 +D 4 ), the outlet diameter of the splitter blade 23 is equal to the outlet diameter of the main bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com