A check valve and its steering pipeline system

A technology of one-way valve and valve body, which is applied in the direction of valve details, control valves, valve devices, etc., can solve the problems of cumbersome operation, high dimensional accuracy requirements at the one-way valve and oil inlet and outlet, and poor connection reliability, etc., to achieve Cooperate with low dimensional accuracy requirements, solve the problem of abnormal oil return noise, and facilitate assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

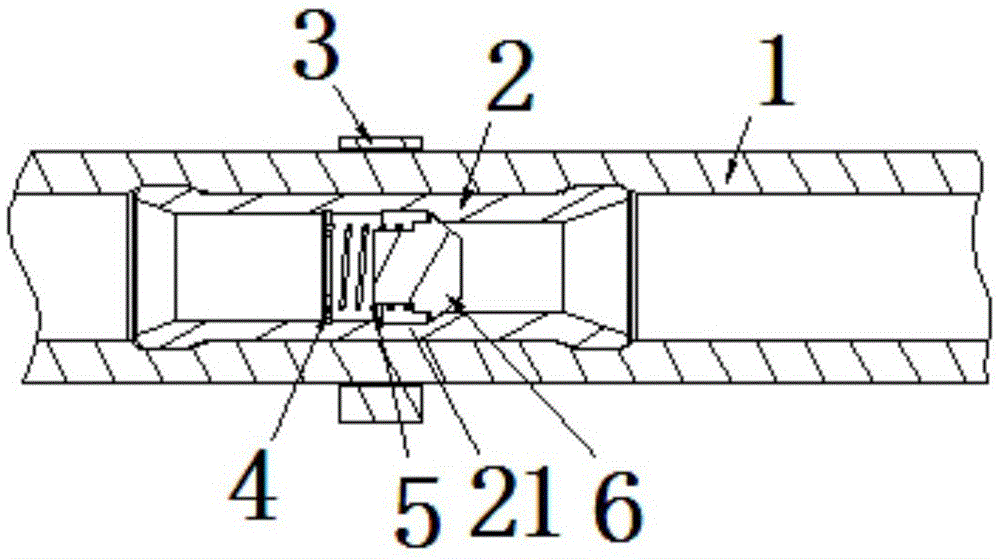

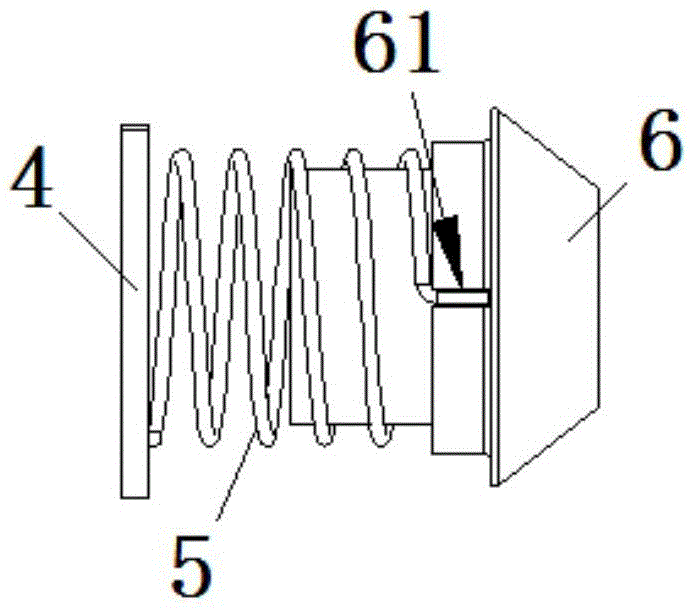

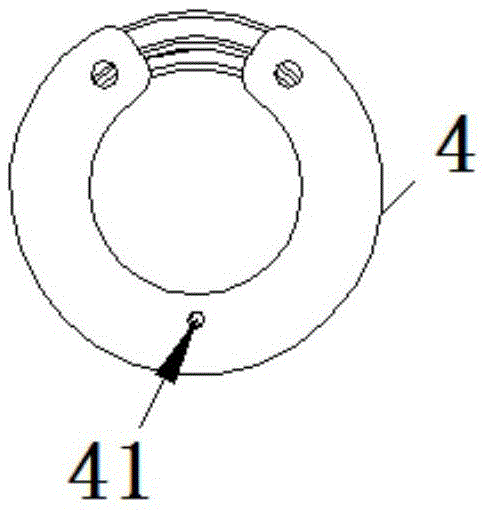

[0024] like Figure 1 to Figure 3 As shown, the one-way valve includes a valve body 2 and a valve core. The valve core is arranged in the valve body 2, wherein the valve body 2 is cylindrical, and the valve core includes an opening circlip 4, a spring 5 and a valve 6. An annular groove 21 is provided on the inner wall of the valve body 2, and the valve 6 is arranged in the annular groove 21. A group of circlip grooves for placing an opening circlip are arranged side by side on the inner wall of the valve body. In the spring groove, the end of the annular groove facing the spring groove is a step perpendicular to the axis of the valve body, and the other end of the annular groove is a conical surface; one end of the valve is a conical surface, and the other end is a cylinder.

[0025] The conic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com