Backlight module

A technology of backlight module and light source, applied in the field of a large number of backlight modules, can solve problems such as increasing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the drawings.

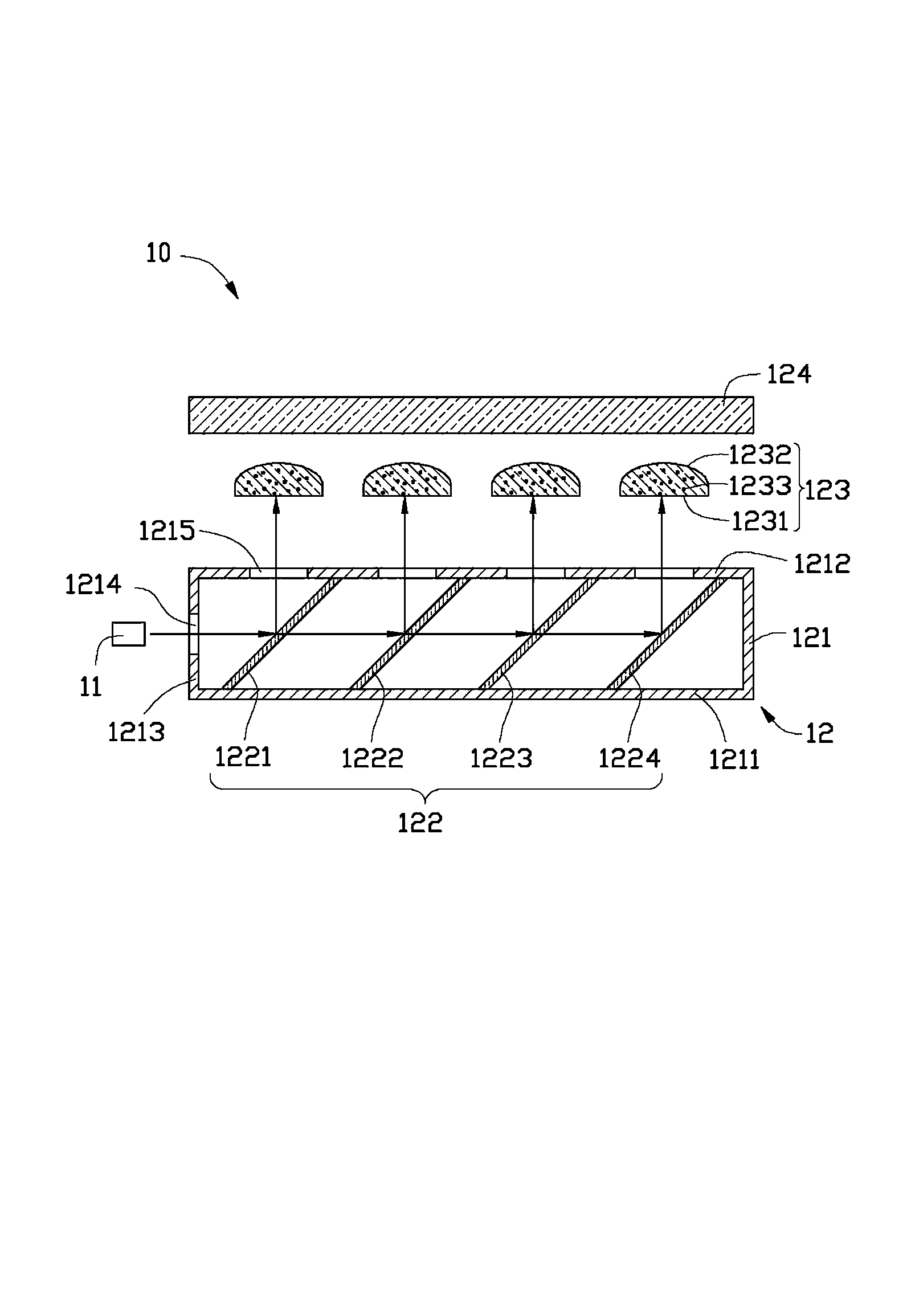

[0015] See figure 1 , the backlight module 10 provided by the first embodiment of the present invention includes a light source 11 and a light guide plate 12 .

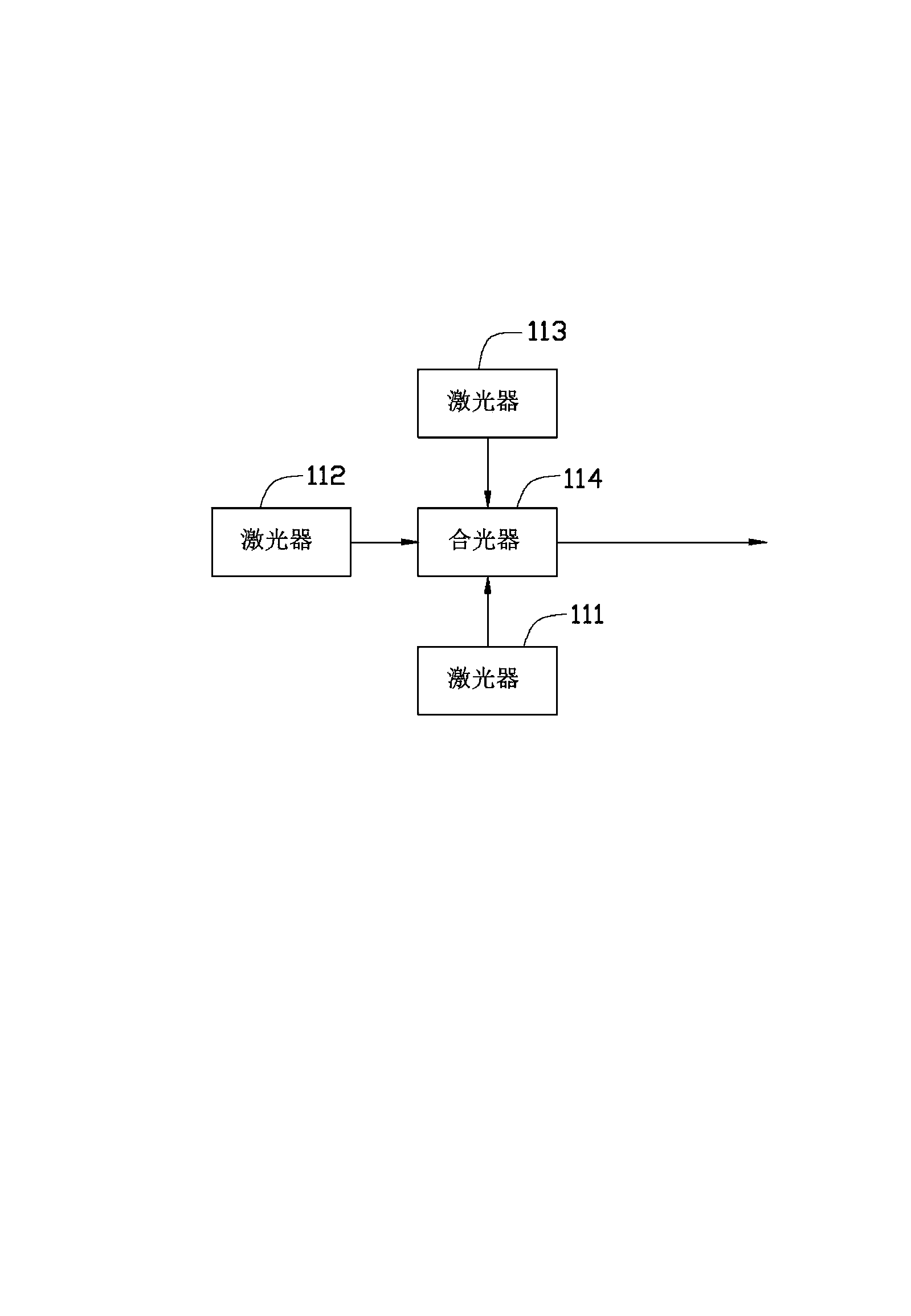

[0016] The light source 11 is arranged on the side of the light guide plate 12 , and the light emitted by the light source 11 is incident from the side of the light guide plate 12 and then exits from the upper surface of the light guide plate 12 . In this embodiment, the light source 11 is a laser light source. According to requirements, the light source 11 includes a first laser light source 111 , a second laser light source 112 , a third laser light source 113 and a light combining prism 114 . See figure 2 , the first laser light source 111 emits red laser light, the second laser light source 112 emits green laser light, and the third laser light source 113 emits blue laser light. The light emitted by the first laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com