Drilling tool internal thread rotary detection device based on magnetic memory effect

A detection device and internal thread technology, which are applied in the direction of force measurement, material magnetic variable, etc. by measuring the change of magnetic properties of materials caused by applied stress, to achieve the effects of simple structure, avoidance of wire winding, and good centering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

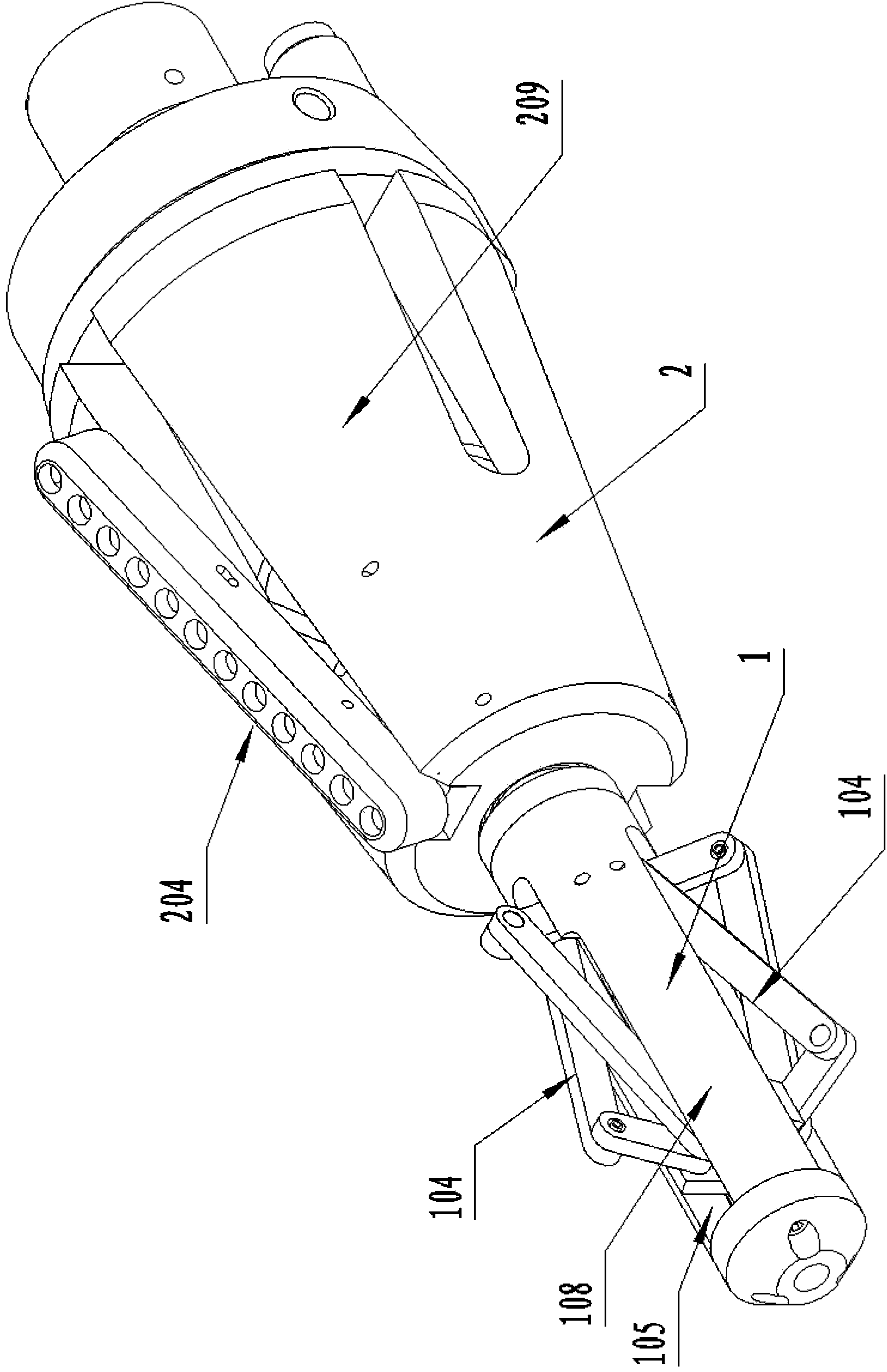

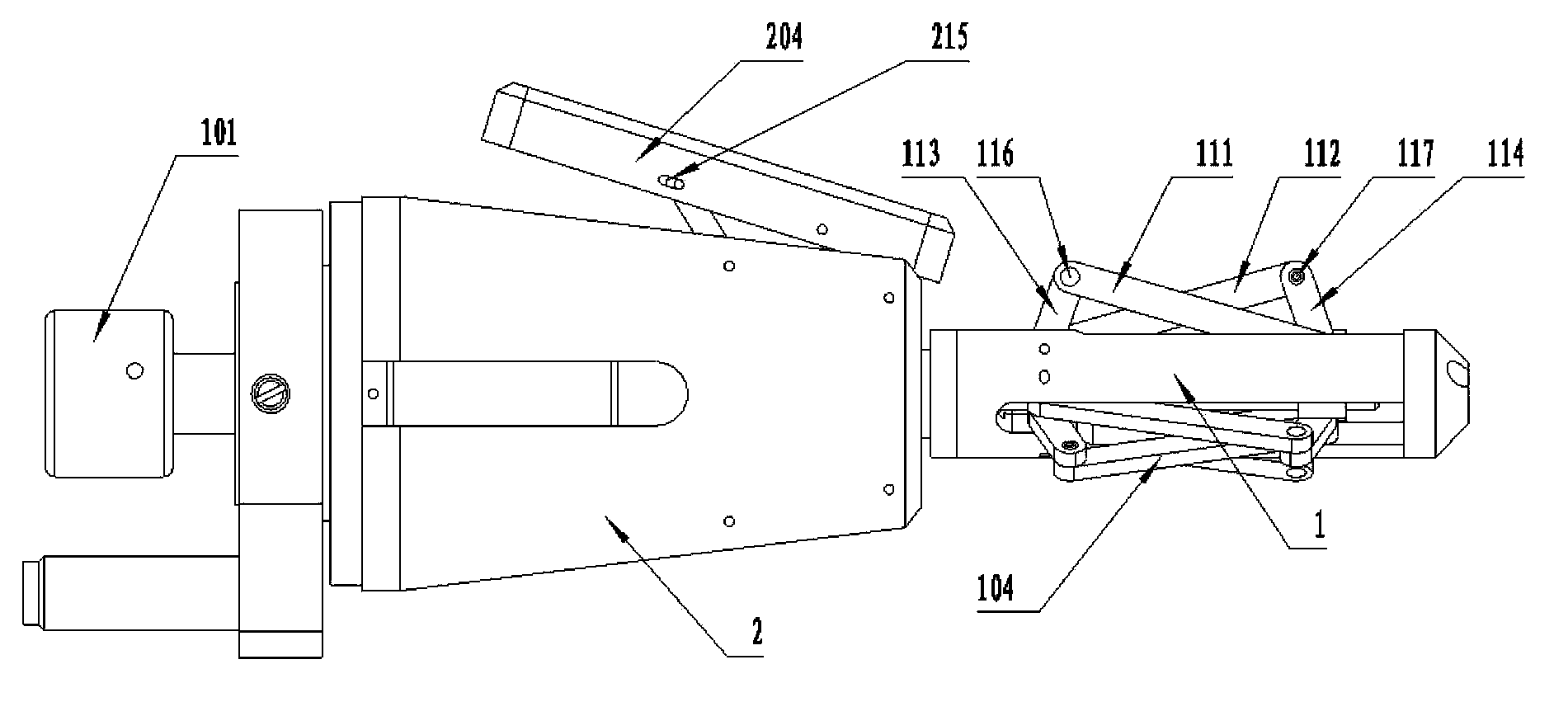

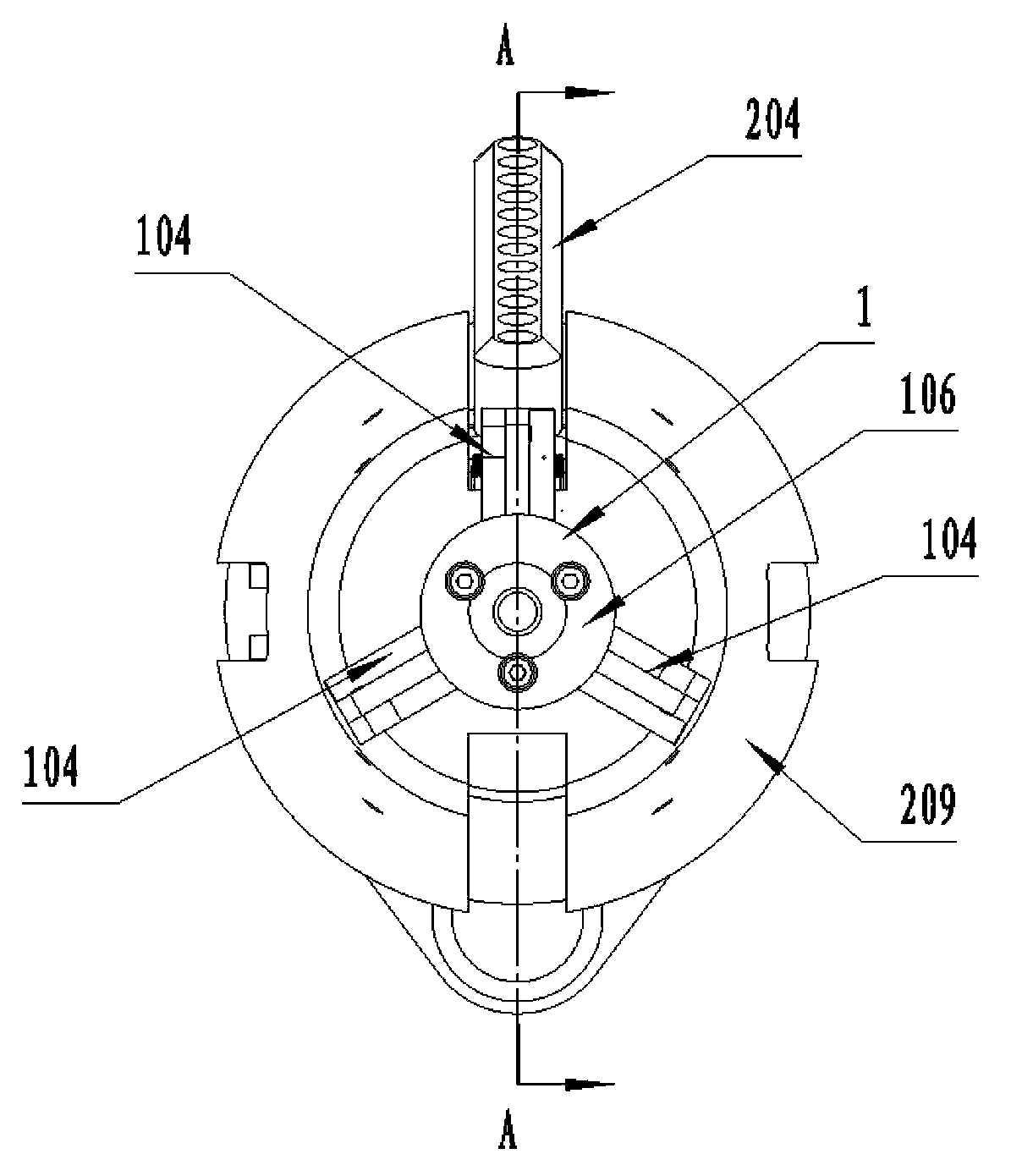

[0030]The magnetic memory effect-based rotary detection device for internal threads of drilling tools according to the present invention will be described in detail below in conjunction with the accompanying drawings. A rotary detection device for internal thread of drilling tools based on magnetic memory effect, said rotary detection device for internal thread of drilling tool based on magnetic memory effect includes: a centering structure component 1 and a rotation detection component connected to the centering structure component 1 2. The centering structure assembly 1 includes a cylindrical main frame 108, one end of the main frame 108 is fixedly connected with one end of the cylindrical hollow rod 103, the main frame 108 and the hollow rod 103 are coaxial, and the main frame 108 and the hollow rod 103 are coaxial. A cylindrical locking rod 102 is sleeved, and the locking rod 102 can rotate relative to the hollow rod 103 with the axis of the hollow rod 103 as the axis, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com