Permanent magnet temperature coefficient open-circuit measuring device and method

A temperature coefficient and measuring device technology, applied in the direction of magnetic performance measurement, etc., can solve the problems of backward measurement methods, no published literature, and difficulty in meeting the requirements of temperature coefficient measurement resolution, so as to solve the problems of low measurement accuracy and resolution, and high sensitivity. Temperature coefficient measurement, the effect of promoting application level improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

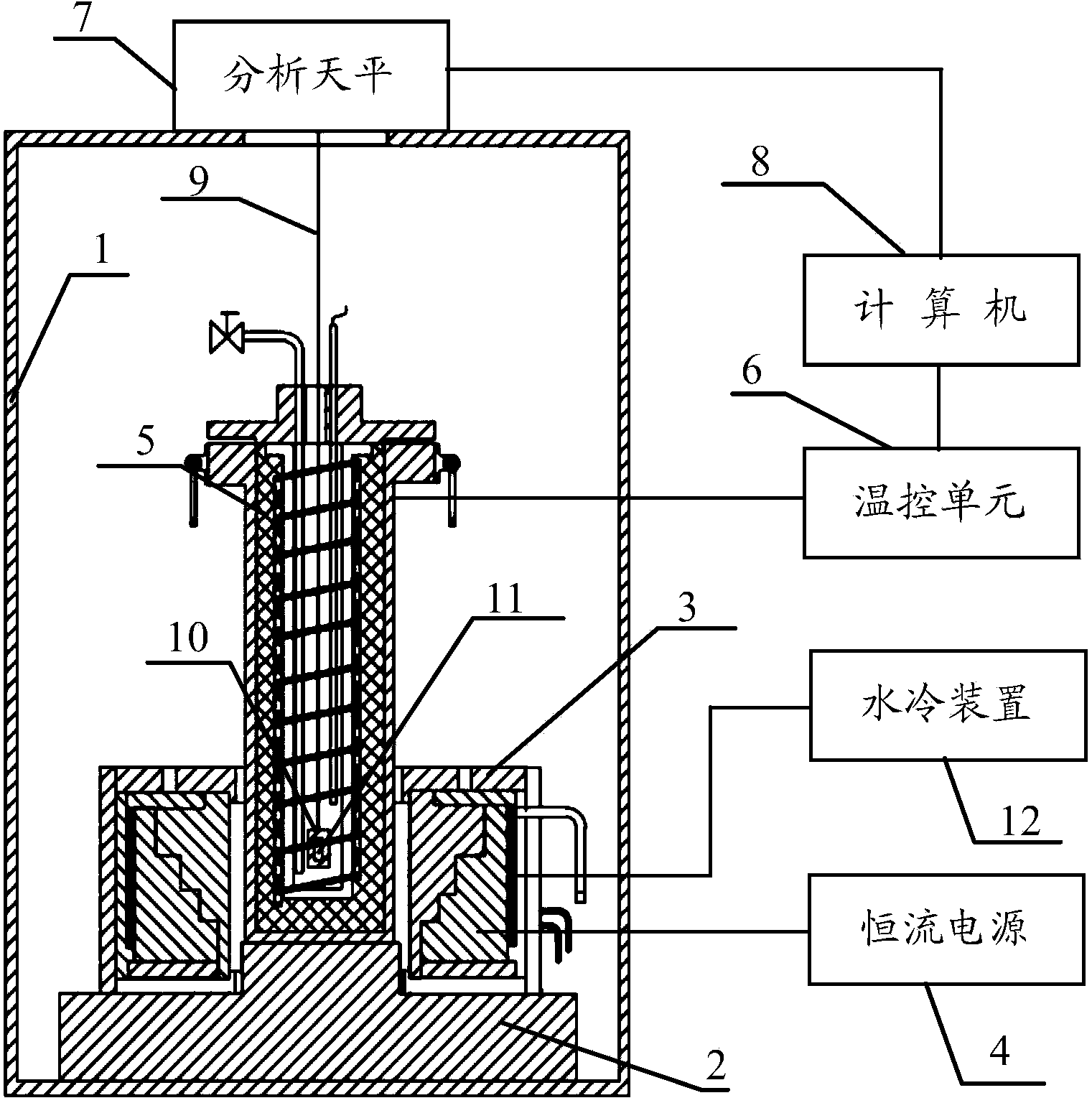

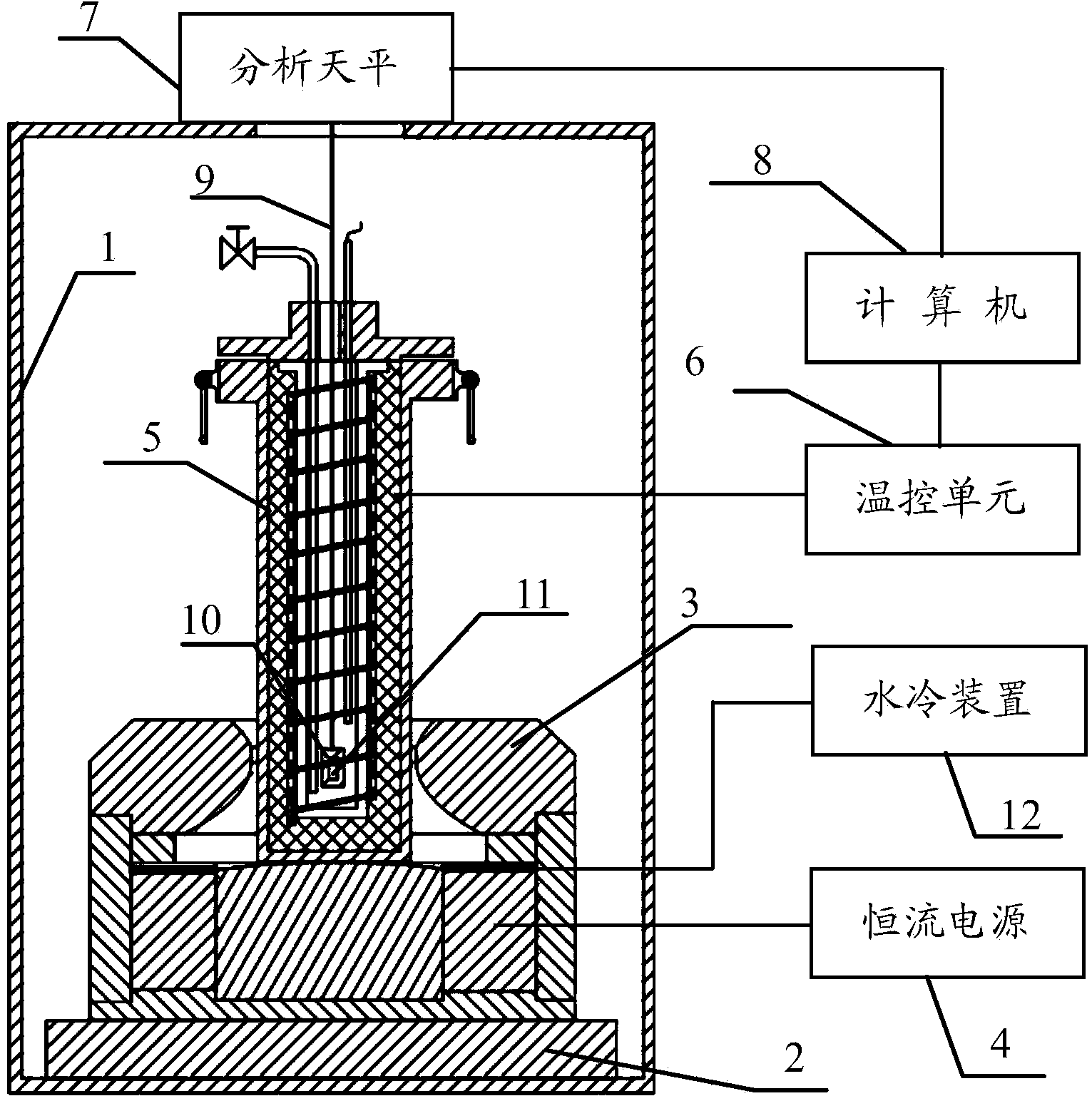

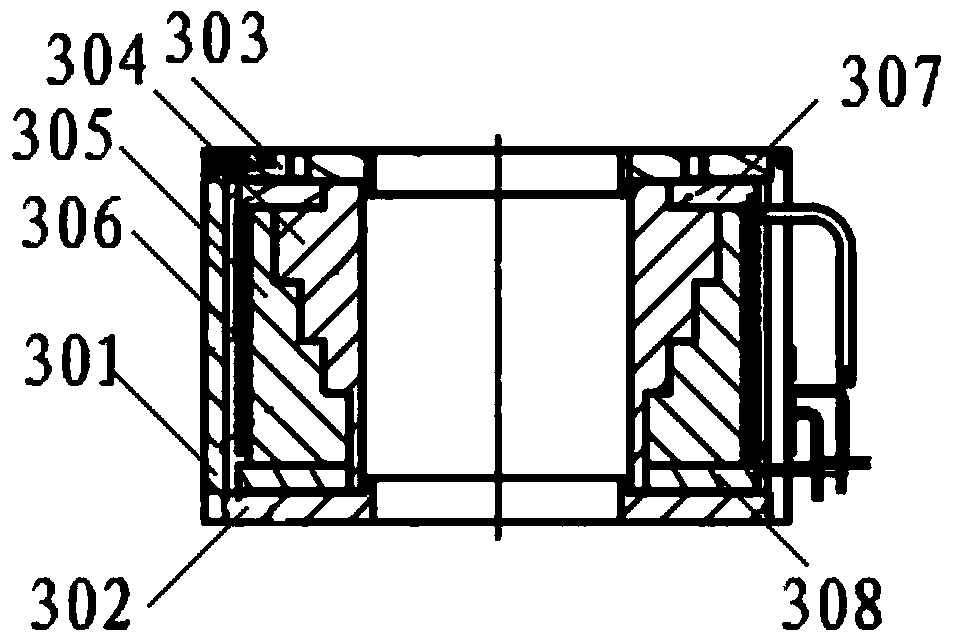

[0039] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0040] The present invention is aimed at the measuring method and measuring instrument of the key magnetic material urgently needed in the fields of aerospace and national defense, and realizes 10 -5 Measurement of the temperature coefficient of the ultra-low temperature coefficient permanent magnet material in the order of / °C.

[0041] The invention proposes to convert magnetic signals into force signals to realize high-sensitivity temperature coefficient measurement. The force formula of an atom with a magnetic moment in an inhomogeneous field is:

[0042] F = F z = m z dBz dz ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com