Touch display device and manufacturing method thereof

A technology of touch display and production method, which is applied in the fields of optics, instruments, electrical digital data processing, etc., to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

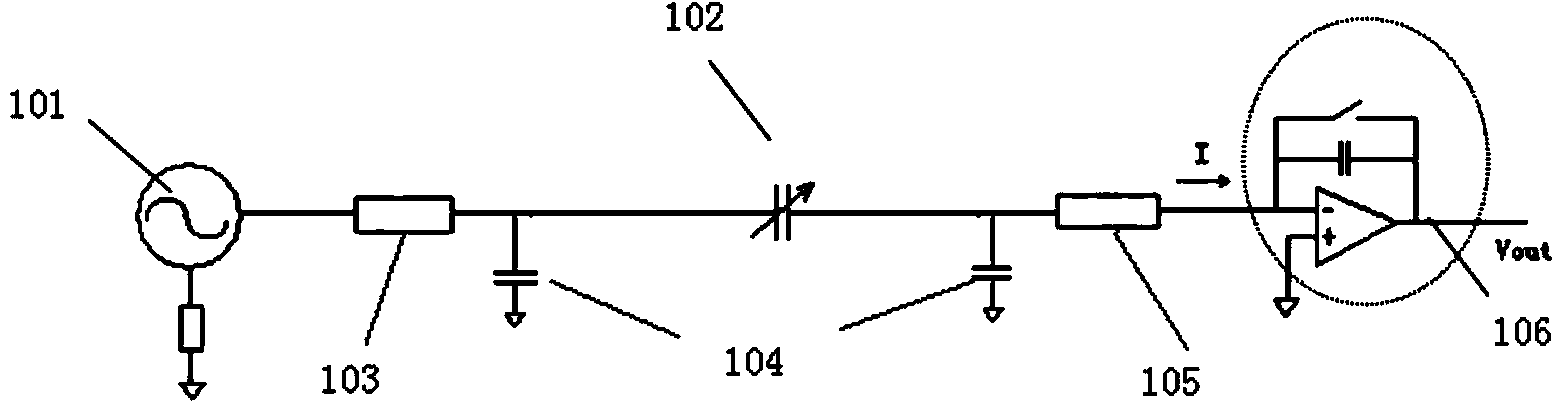

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The touch display device of this embodiment is based on the on-cell technology in the embedded touch technology,

[0044]Specifically, the touch display device provided in this embodiment includes a first substrate and a second substrate oppositely arranged, a liquid crystal layer between the first substrate and the second substrate, and a separation layer formed on the first substrate. separated receiving electrodes, on the first substrate, a separated first transparent electrode is arranged below the receiving electrodes in the projection direction of the first substrate along the display electrodes on the second substrate , the first transparent electrode is separated from the receiving electrode by an insulating layer, and the first transparent electrode is used for connecting to a fixed potential. Wherein, the formation of the liquid crystal layer may be by dripping liquid crystals between the two substrates after the first substrate and the second substrate are bo...

Embodiment 2

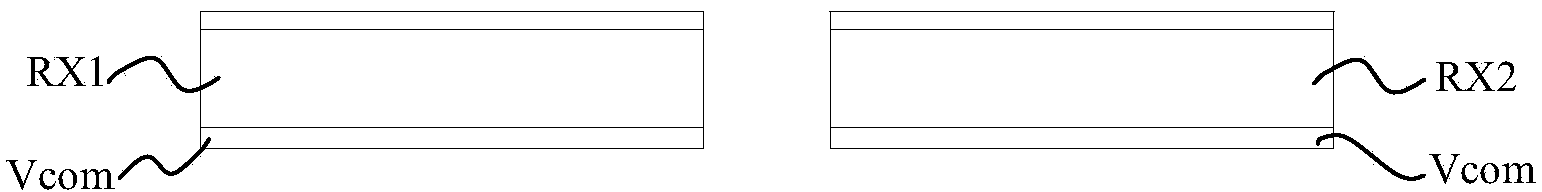

[0048] This embodiment is based on the embedded in-cell technology, the emitter electrode is located on the side of the array substrate, and the receiving electrode is located on the side of the color filter substrate. Here, the first substrate is the color filter substrate, and the second substrate is the array substrate as an example. This embodiment will be described.

[0049] Based on the above situation, this embodiment proposes a touch display device with a new structure, referring to Figure 4 As shown, it includes: a first substrate 1 and a second substrate 6 oppositely arranged, a liquid crystal layer 5 formed between the first substrate 1 and the second substrate 6, and a liquid crystal layer formed on the first substrate 1 Separated receiving electrodes RX, the color filter layer 4 is formed on the first substrate 1 , and an array structure is formed on the second substrate 6 , such as gate, source-drain, common electrode and other structures.

[0050] The array su...

Embodiment 3

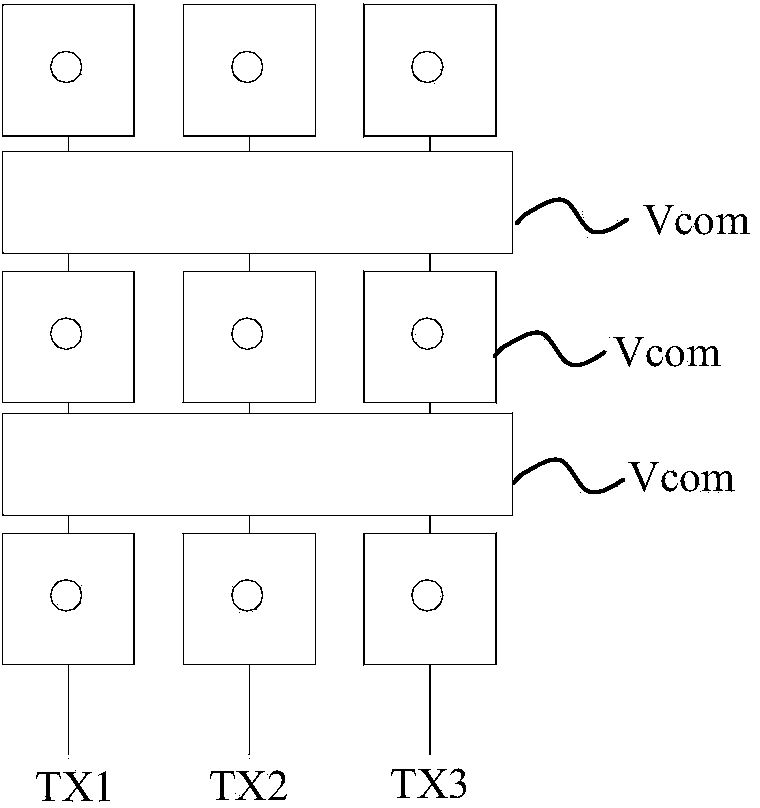

[0055] This embodiment is based on the embedded in-cell touch technology of the ADS display mode, and a touch display device in which the emitting electrodes and the receiving electrodes are both on the side of the color filter substrate.

[0056] The structure of the touch display device in this embodiment is as follows: Figure 7 As shown, it includes: a first substrate 1 and a second substrate 6 oppositely arranged, a liquid crystal layer 5 formed between the first substrate 1 and the second substrate 6, and a liquid crystal layer formed on the first substrate 1 The receiving electrodes RX and the transmitting electrodes TX are arranged at intervals, a color filter layer is formed on the first substrate 1, and an array structure is formed on the second substrate 6, such as Figure 7 The display electrode 7 shown in (for example, including gate layer, source and drain, pixel electrode and common electrode, etc.); in order to eliminate the coupling capacitance between the rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com