Composite-magnetic-pole electromagnetic iron remover

An iron remover, electromagnetic technology, applied in the direction of magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problem of being unable to be sucked up at the same time, when one end is sucked up, the other end is supported, electromagnetic iron remover Can not work normally, can not meet the on-site operation and other problems, to achieve the effect of simple structure, low maintenance cost, low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical scheme of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

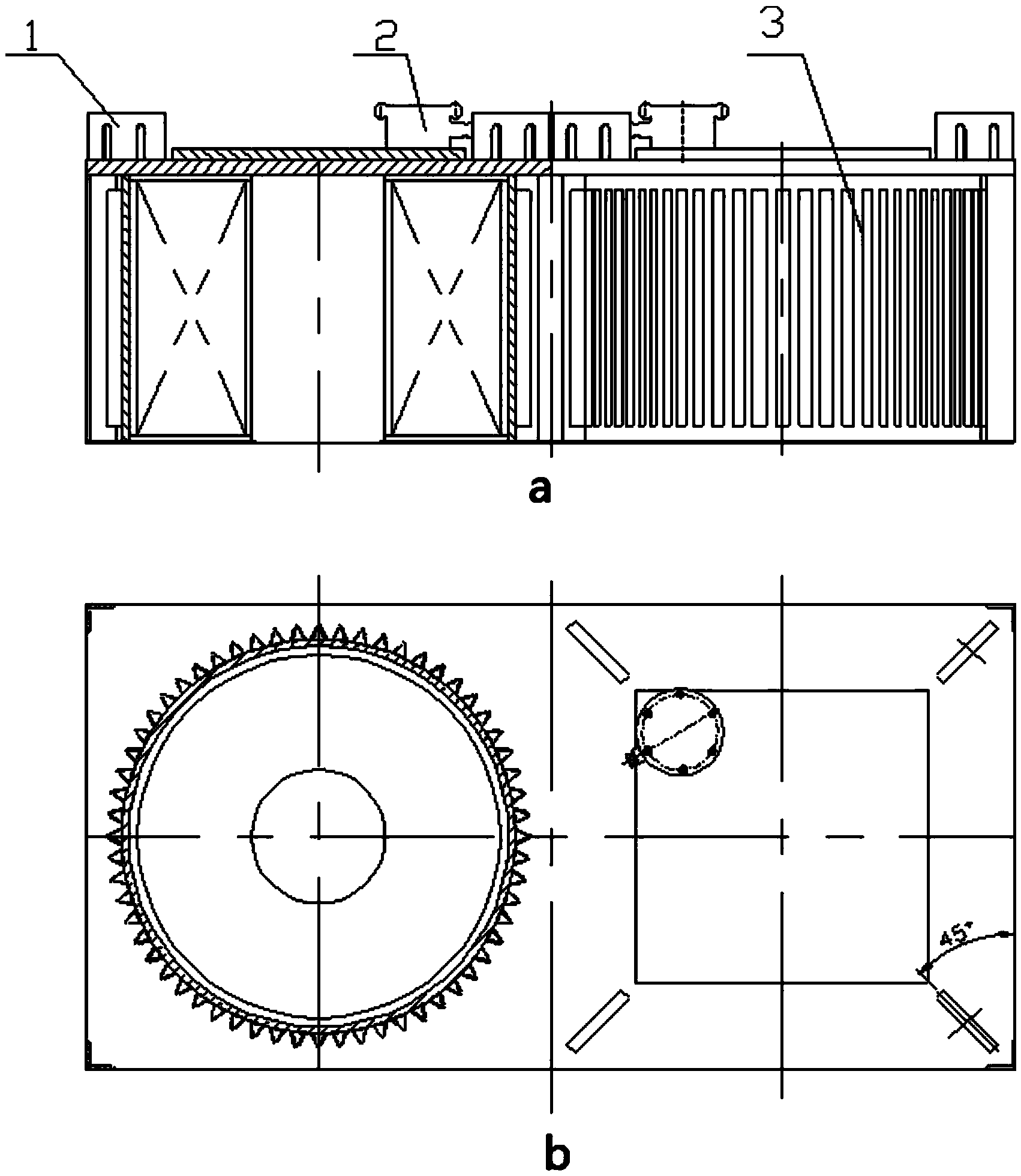

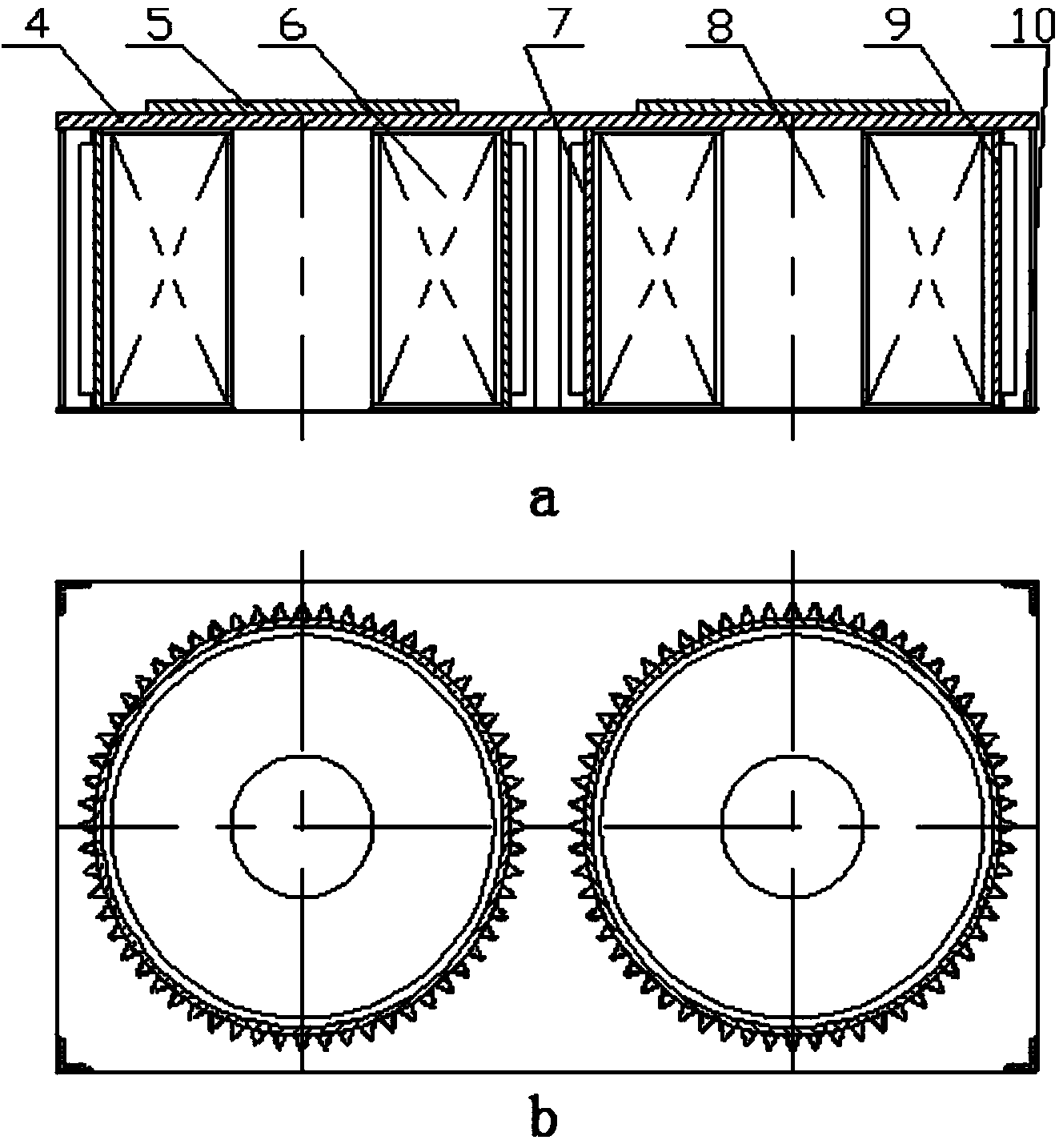

[0015] Reference Figure 1-Figure 2 , A composite magnetic pole electromagnetic separator includes a junction box 1, a lifting lug 2 and a magnetic system 3. The magnetic system part is composed of coil 6, iron core 8, cylinder 7, heat sink 9, large yoke plate 4, small yoke plate 5 and bottom plate 10. And it consists of two sets of coils, two iron cores and two cylinders. The junction box part uses two junction boxes corresponding to two sets of coils. The magnetic system is controlled by the electric control box through two junction boxes. Used in conjunction with metal detectors. The two sets of coils of the composite magnetic pole electromagnetic separator can work simultaneously, and the two coils can work independently.

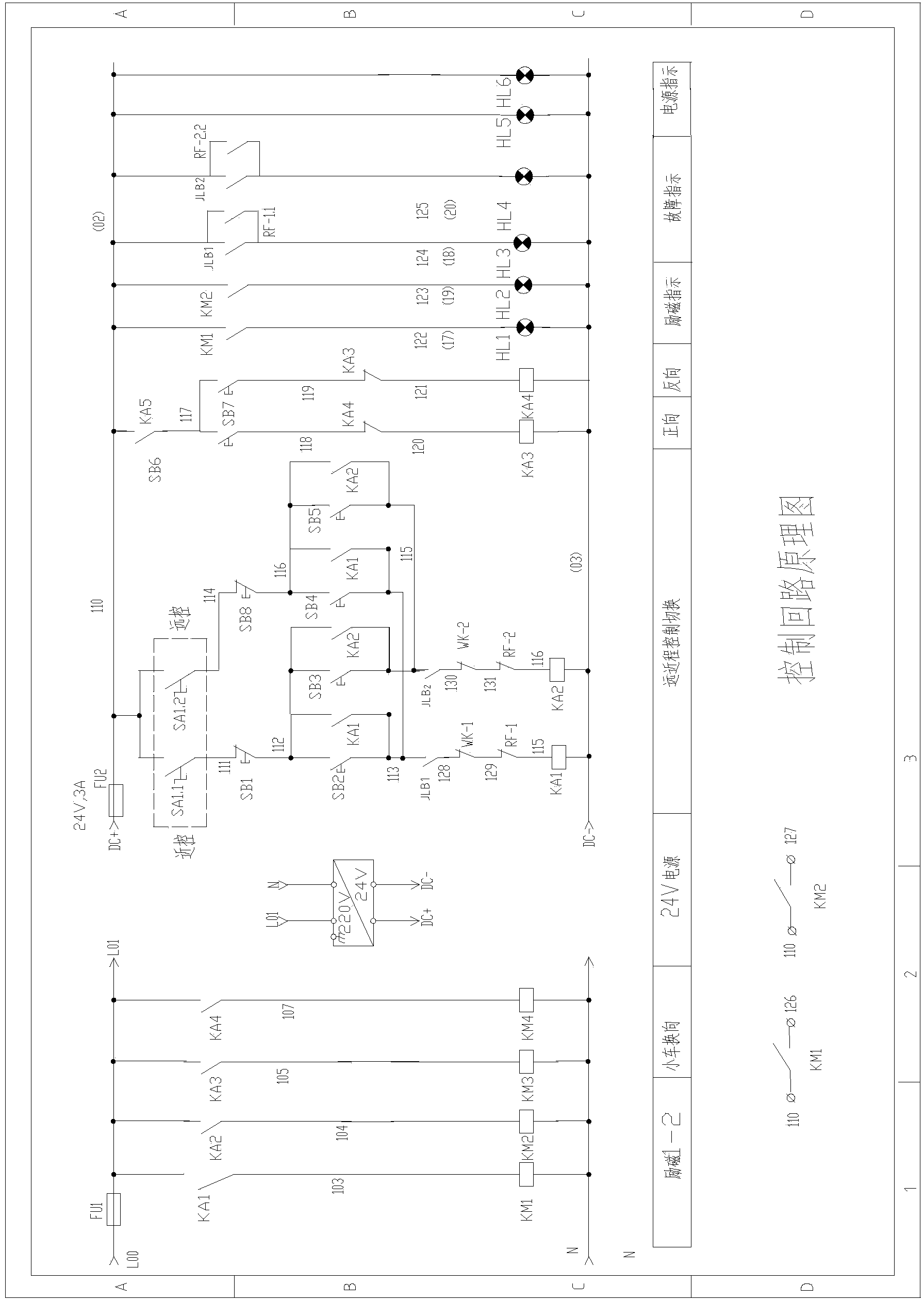

[0016] The electric control box for the composite magnetic pole electromagnetic separator, and it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com