Wind power sand selecting device with adjustable product fineness modulus

A fineness modulus, adjustable technology, used in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. Wind selection effect, accurate grading, and the effect of increasing contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below through specific embodiments.

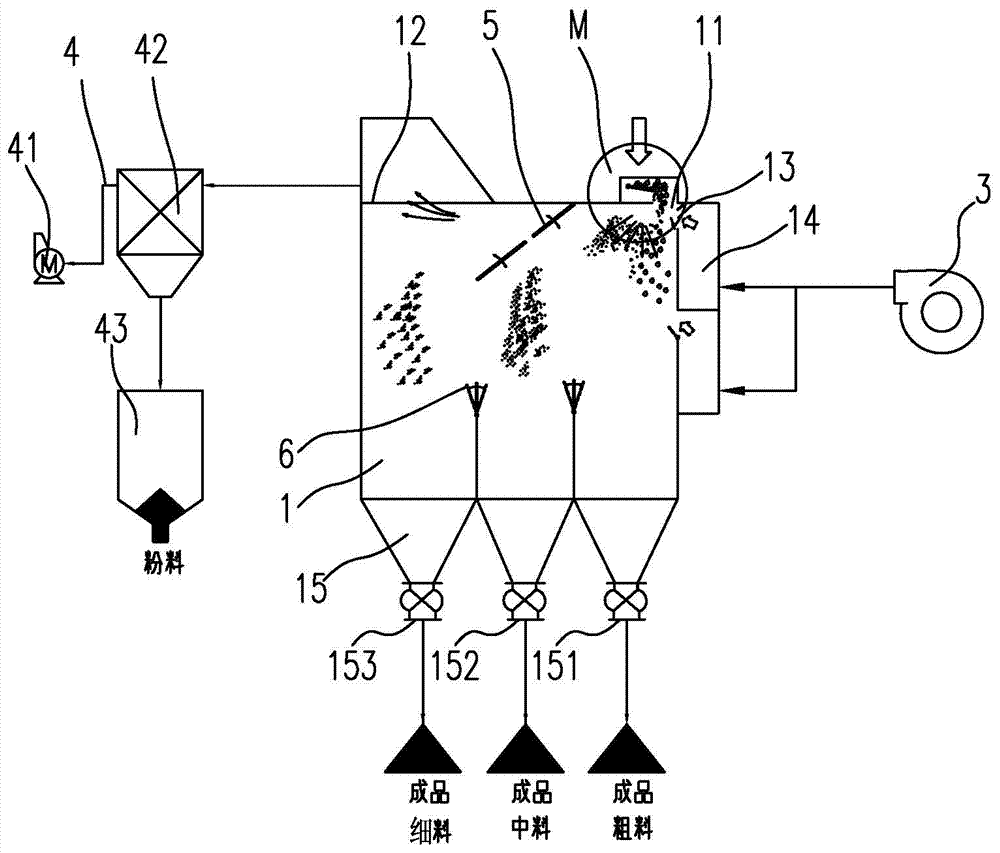

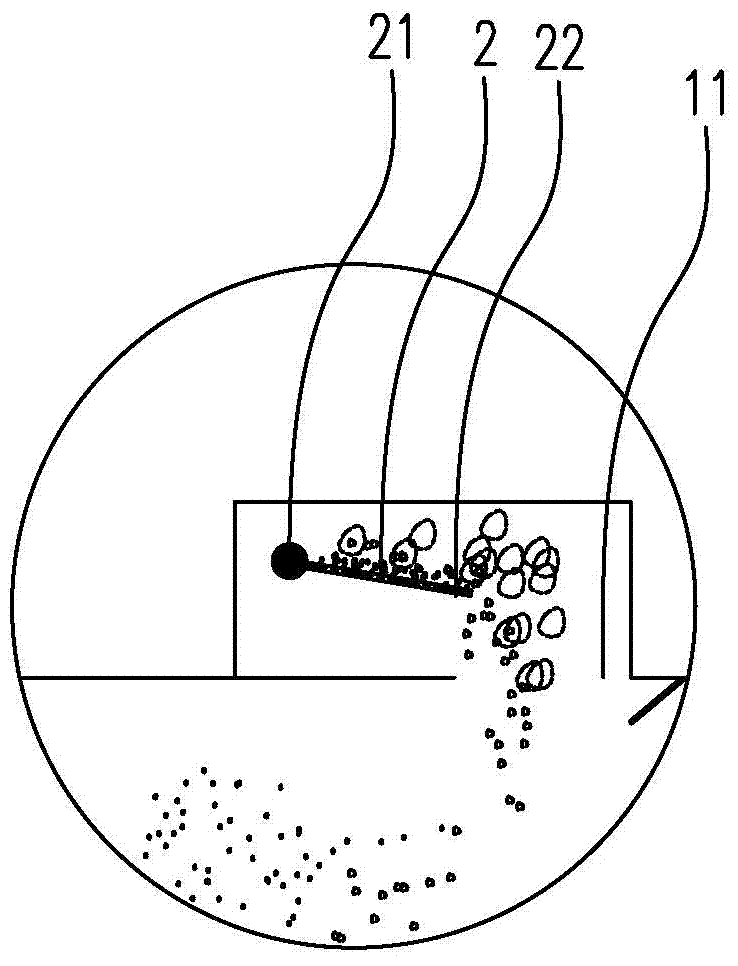

[0015] refer to figure 1 As shown in the figure, a wind power sand selection equipment with adjustable product fineness modulus includes a winnowing chamber 1, a vibration dispersion device 2, an air supply device 3, a dust removal device 4, a windshield 5 and a material baffle 6;

[0016] The air separation bin 1 is provided with a feed inlet 11, a dust removal port 12, an air inlet 13, an air equalization chamber 14, and a discharge port 15. The left and right sides of the top of winnowing bin 1,

[0017] There are two air inlets 13, and the two air inlets 13 are opened below the feed inlet 11 and distributed longitudinally along the side wall of the air selection bin 1;

[0018] The uniform air chamber 14 is arranged between the air inlet 11 and the air supply device 3 so that the wind speed and angle distribution in the width direction of the air inlet 11 of the winnowing bin 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com