Split type crystallizer

A crystallizer and split-type technology, which is applied in the field of metal smelting and casting, can solve the problems of high mold maintenance cost, short mold service life, and low mold production efficiency, so as to improve processing convenience, reduce maintenance cost, and prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The content of the present invention will be described below in conjunction with specific embodiments.

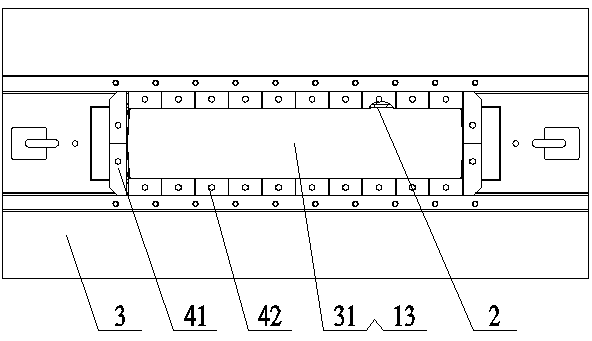

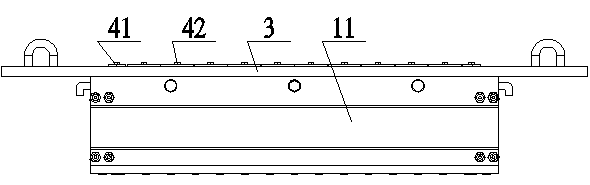

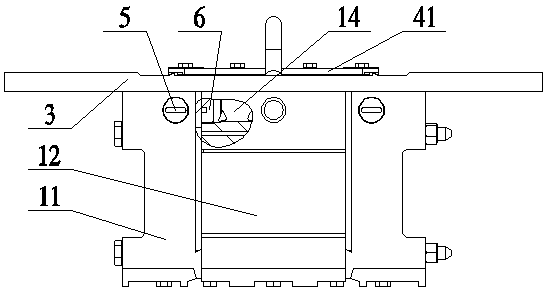

[0018] Such as Figure 1 to Figure 5 Shown is a schematic structural view of a split crystallizer described in the present invention. A split type crystallizer according to the present invention comprises: two large face walls 11, two small face walls 12 and several graphite sheets 2, the large face walls 11 and the small face walls 12 jointly form a crystallization channel 13, so The graphite sheets 2 are strip-shaped and vertically arranged on the inner wall of the crystallization channel 13 . By setting the graphite sheet 2 on the inner wall of the crystallization channel 13, the high temperature resistance performance is improved compared with the chrome-plated crystallization channel 13 on the inner wall, thereby prolonging the service life of the crystallizer; structure, it is convenient to replace the damaged graphite sheet 2, thereby reducing the maintenanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com