Surface exposure molding device and molding method based on digital fabrication of photosensitive resin

A technology of photosensitive resin and liquid photosensitive resin, which is applied in the field of surface exposure rapid prototyping equipment, can solve the problems of high production cost and low curing efficiency, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

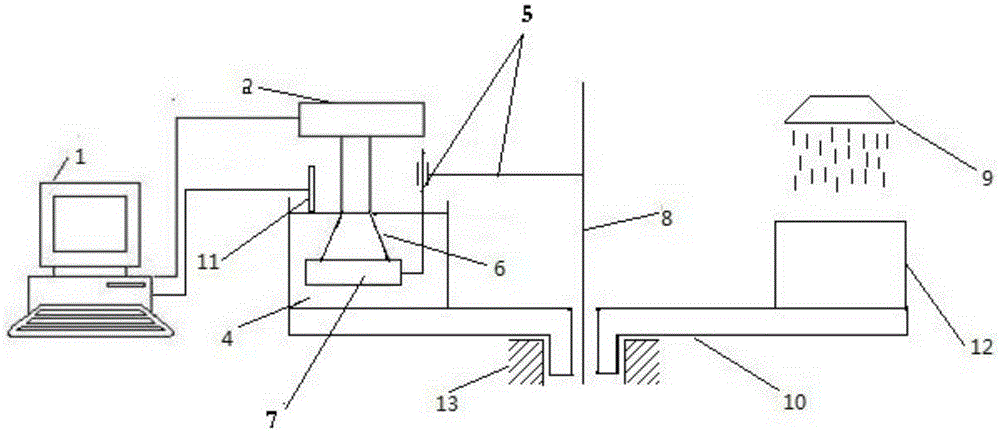

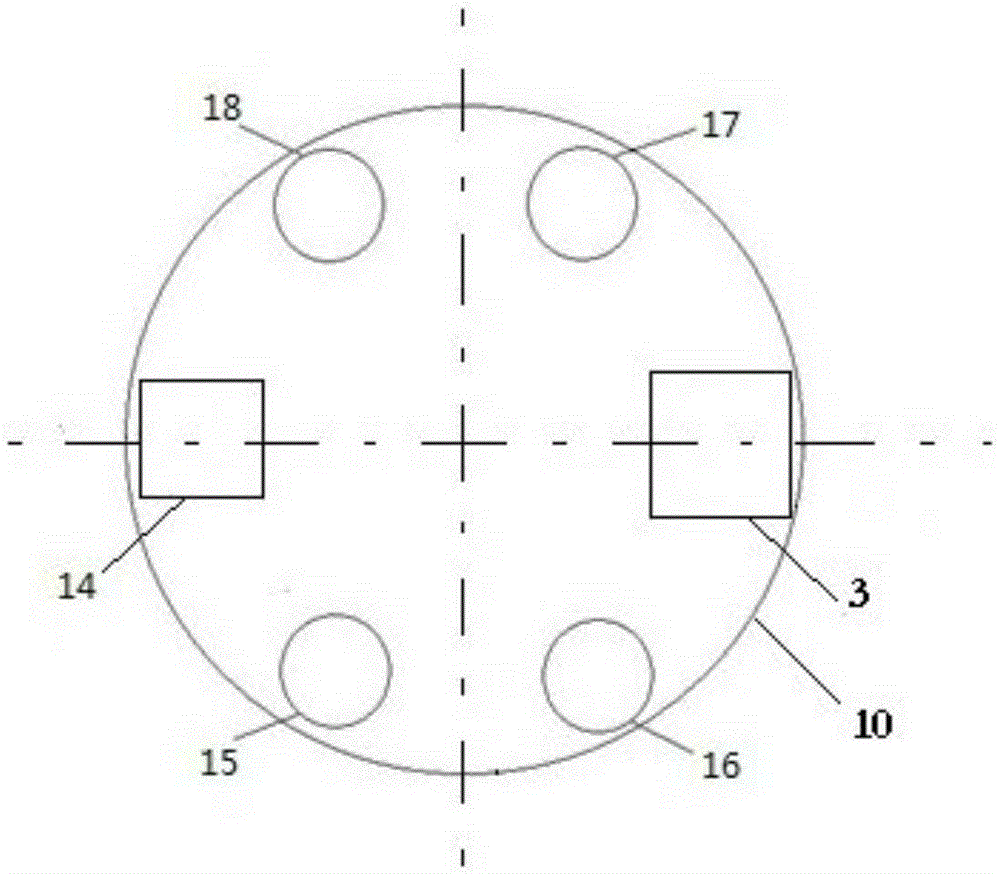

[0043] The surface exposure rapid prototyping device based on photosensitive resin digitization of the present invention has a structure such as figure 1 and figure 2 As shown, a turntable 10 is included, the bottom of the turntable 10 is installed on the frame 13, the center of the turntable 10 is vertically provided with a worktable rotating shaft 8, and the worktable rotating shaft 8 is connected with a lifting workbench 7 through a lifting shaft 5. The upper surface is respectively provided with an exposure station 14, a washing station 3 and a plurality of working areas, the upper part of the washing station 3 is provided with a cleaning tank 12, the upper part of the cleaning tank 12 is provided with a workpiece washing device 9, and the upper part of each working area is provided There is a resin tank, and a pattern generator 2 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com