Online automatic EVA (ethylene vinyl-acetate copolymer) laying and cutting machine

An automatic laying and cutting machine technology, applied in the directions of lamination auxiliary operation, sending objects, lamination, etc., can solve the problems of low production efficiency and high labor intensity of workers, and achieve work efficiency improvement, labor intensity reduction, and precise location. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

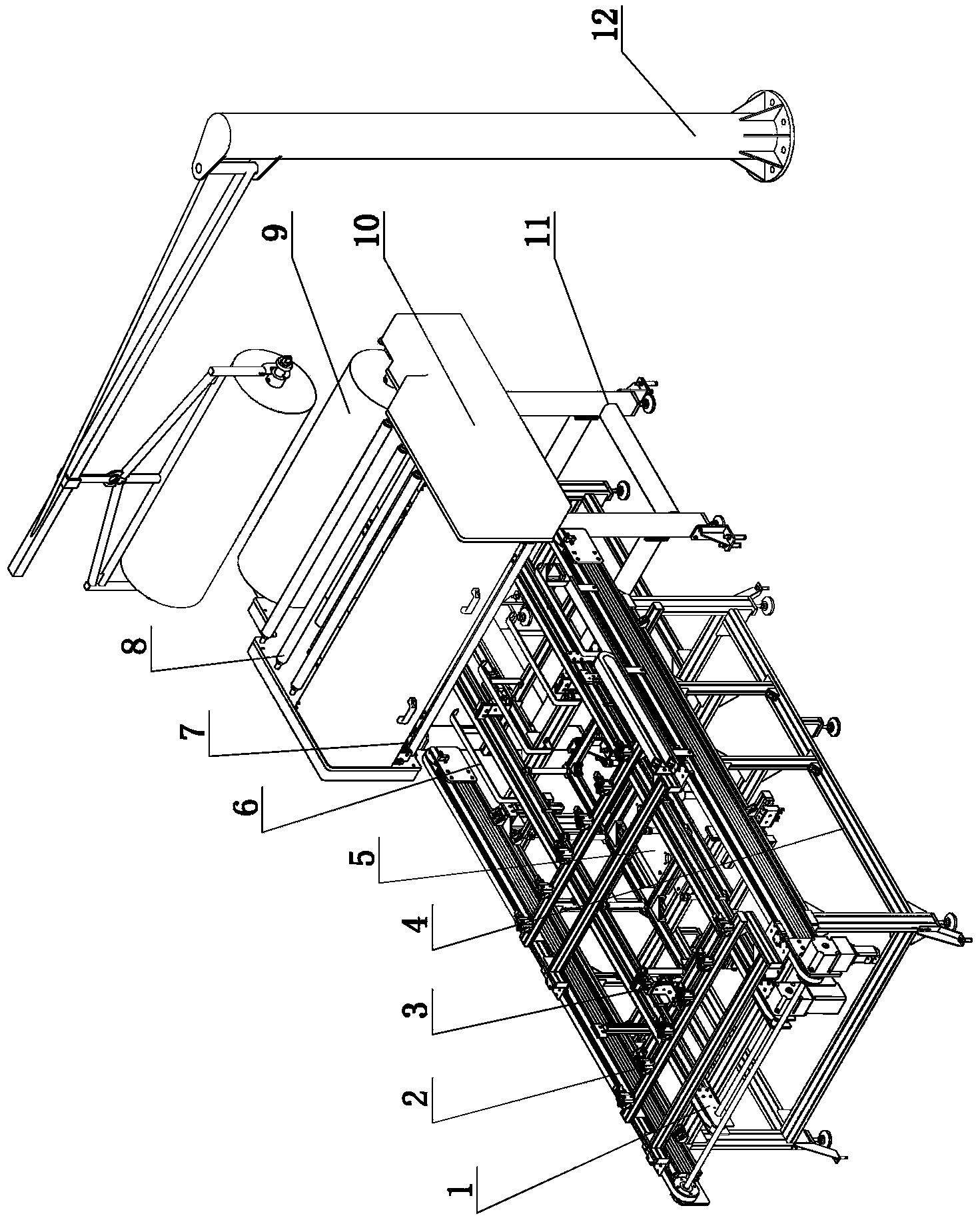

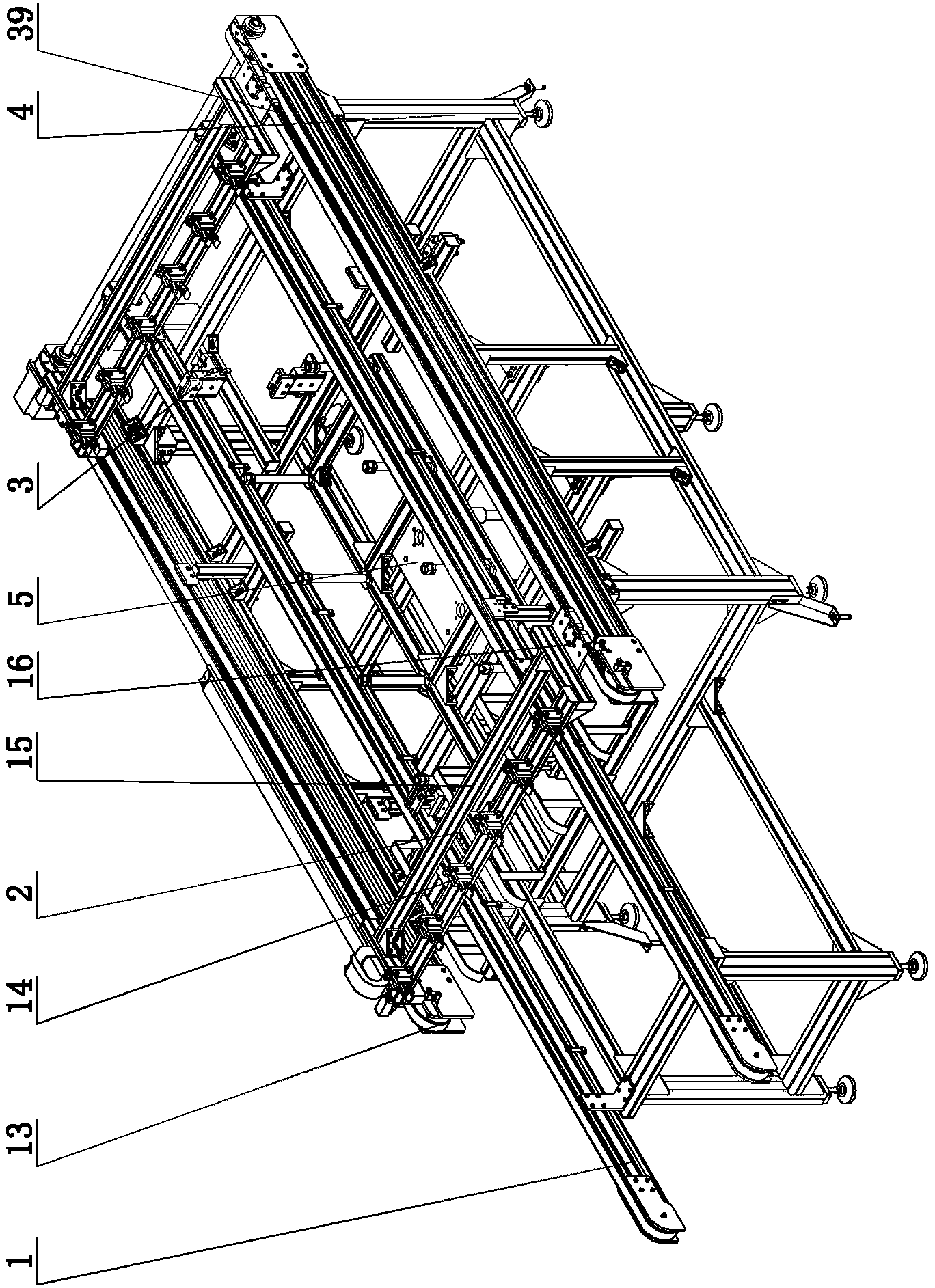

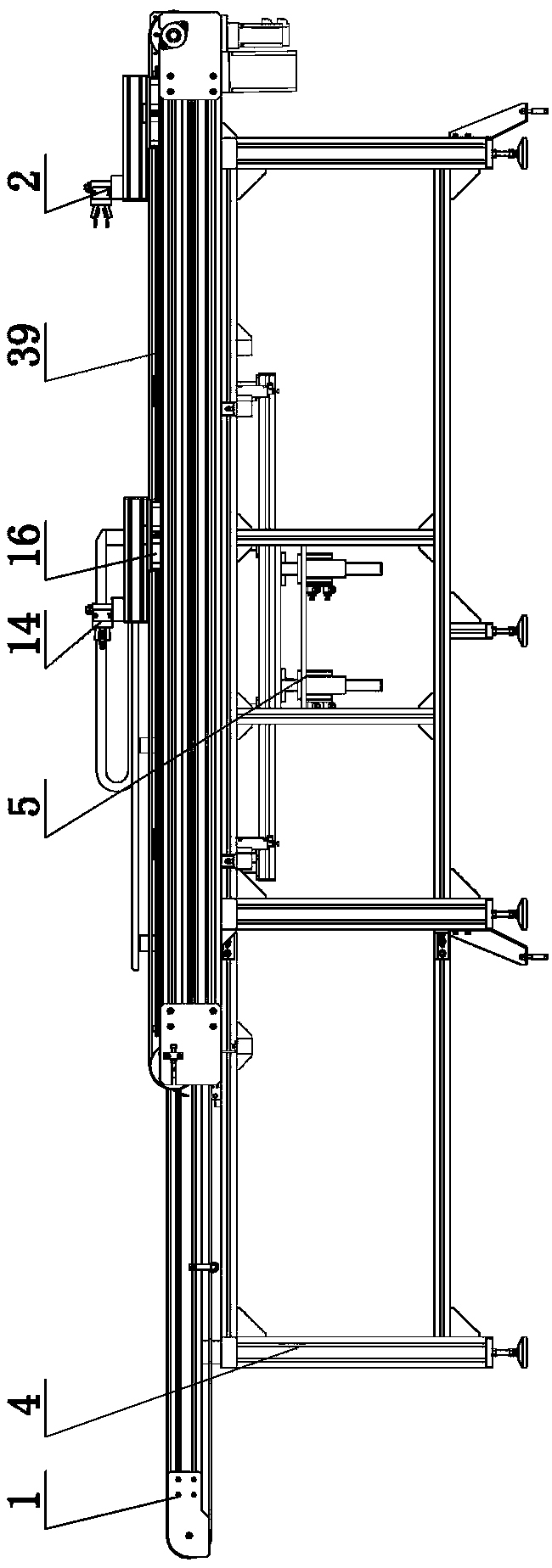

[0023] The present invention includes a transmission mechanism 1 arranged on a frame 4, a jacking mechanism 5 is arranged in the middle of the frame 4, a support frame 11 is provided corresponding to the end of the transmission mechanism 1, and a transverse slideway 34 is arranged on the support frame 11, The transverse slide 34 is provided with a cutting mechanism 10; the frame 4 is provided with a laying mechanism 2 corresponding to the cutting mechanism 10; The end links to each other with the slide rail 39 on both sides of the frame 4 and the conveyor belt 13 through the slide block 16.

[0024] Described cutting mechanism 10 comprises the cutting frame 18 that links to each other with transverse slideway 34, is provided with booster push rod 35 between cutting frame 18 and transverse slideway 34; Cutting mechanism 7, described unwinding mechanism 9 is the air expansion shaft 21 that links to each other with motor; Described cutting mechanism 7 comprises the upper cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com