Control device and control method of heating system of coal power boiler for vehicle

A heating system and control method technology, applied in vehicle components, transportation and packaging, heating/cooling equipment, etc., can solve problems such as inapplicability, and achieve the effects of reducing work energy consumption, wide adaptability, and safety assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

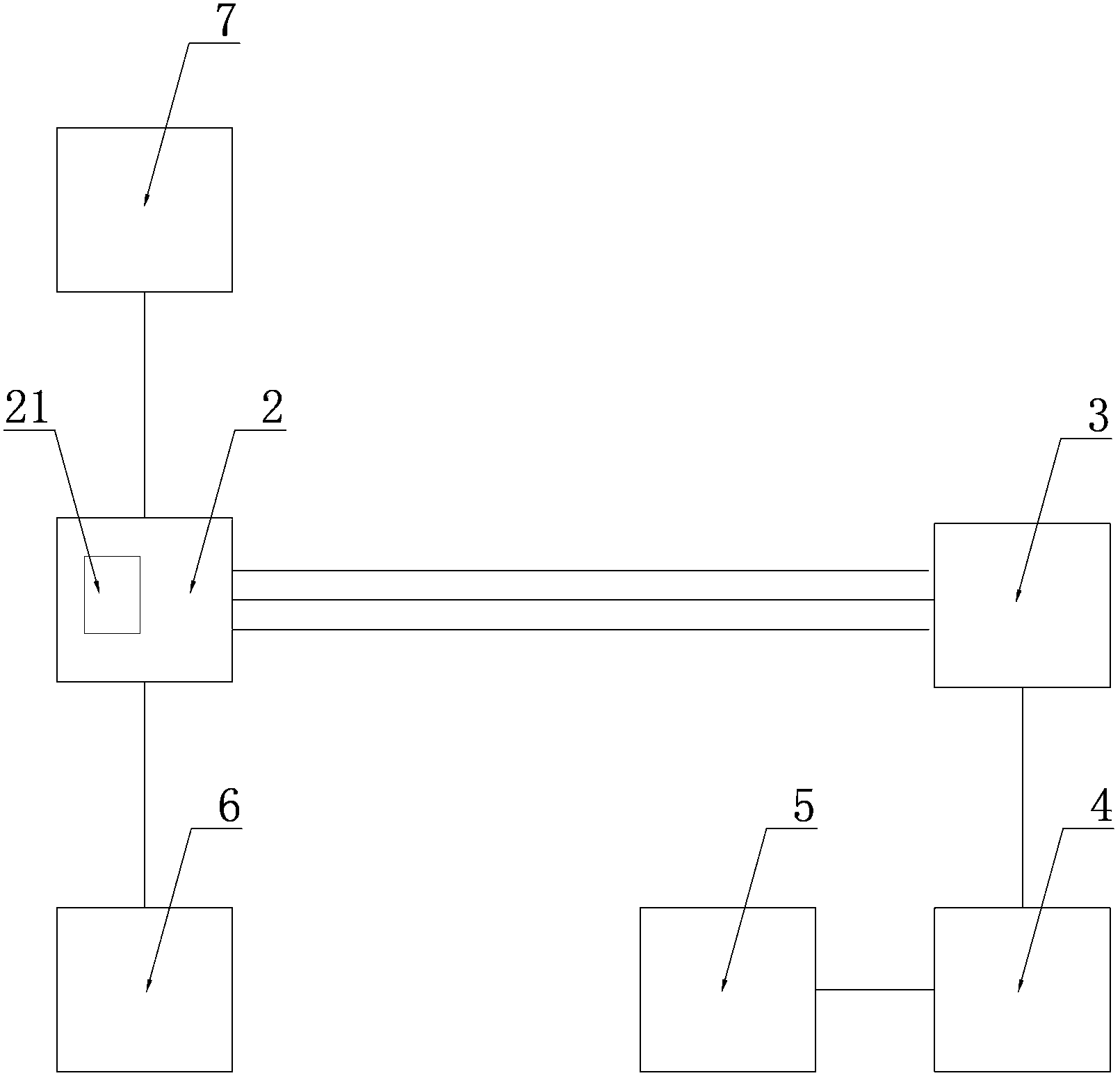

[0038] Such as figure 1 As shown, a control device for a heating system of a coal-fired boiler for a vehicle includes: a boiler for heating water 2, a heating tube 21 with adjustable heating gear, and a radiator 3 for dissipating heat in the cabin 4, so The heating pipe 21 is arranged in the boiler 2, and the radiator 3 and the boiler 2 are connected through a circulating pipeline. The boiler 2 is also provided with a water temperature sensor 6 for detecting the water temperature in the boiler 2 and a water level sensor 7 for detecting the water level of the boiler. A temperature sensor 5 for detecting the temperature in the cabin 4 is also provided in the cabin 4.

[0039] The heating pipe 21, the temperature sensor 5, the water temperature sensor 6 and the water level sensor 7 are respectively connected to a control panel 1 provided with a display gear, an alarm signal and a heating mode through a control system.

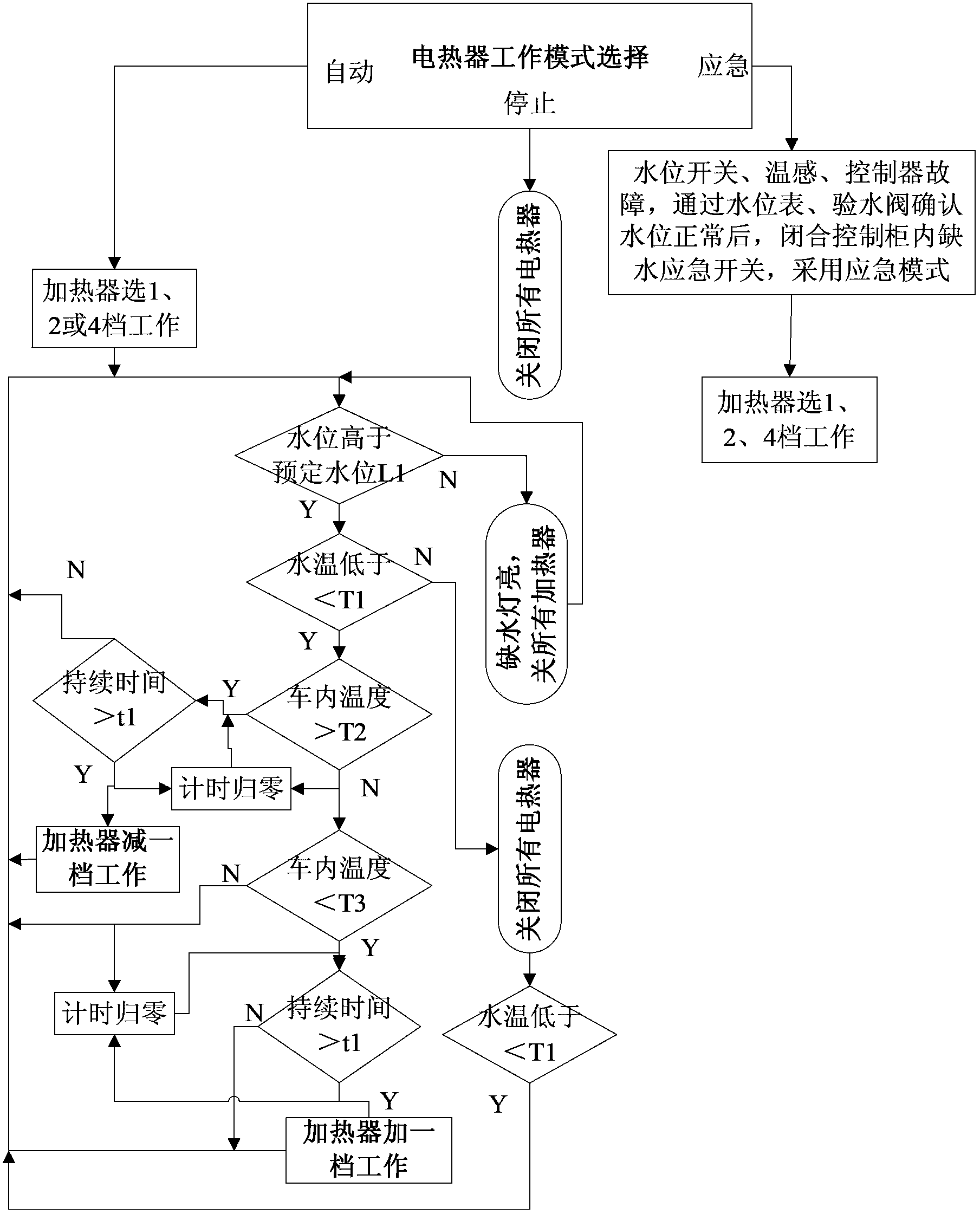

[0040] Such as figure 2 As shown, a method of controlling the h...

Embodiment 2

[0055] Such as Figure 4 As shown, in this embodiment, the heating tube 21 provided in the boiler 2 is provided with 4 heating gears, and the heating power of the heating tube corresponding to the added gear is set as the maximum heating power of the heating tube. Thus, the temperature value in the cabin 4 can be kept within the rated temperature range in severe cold areas.

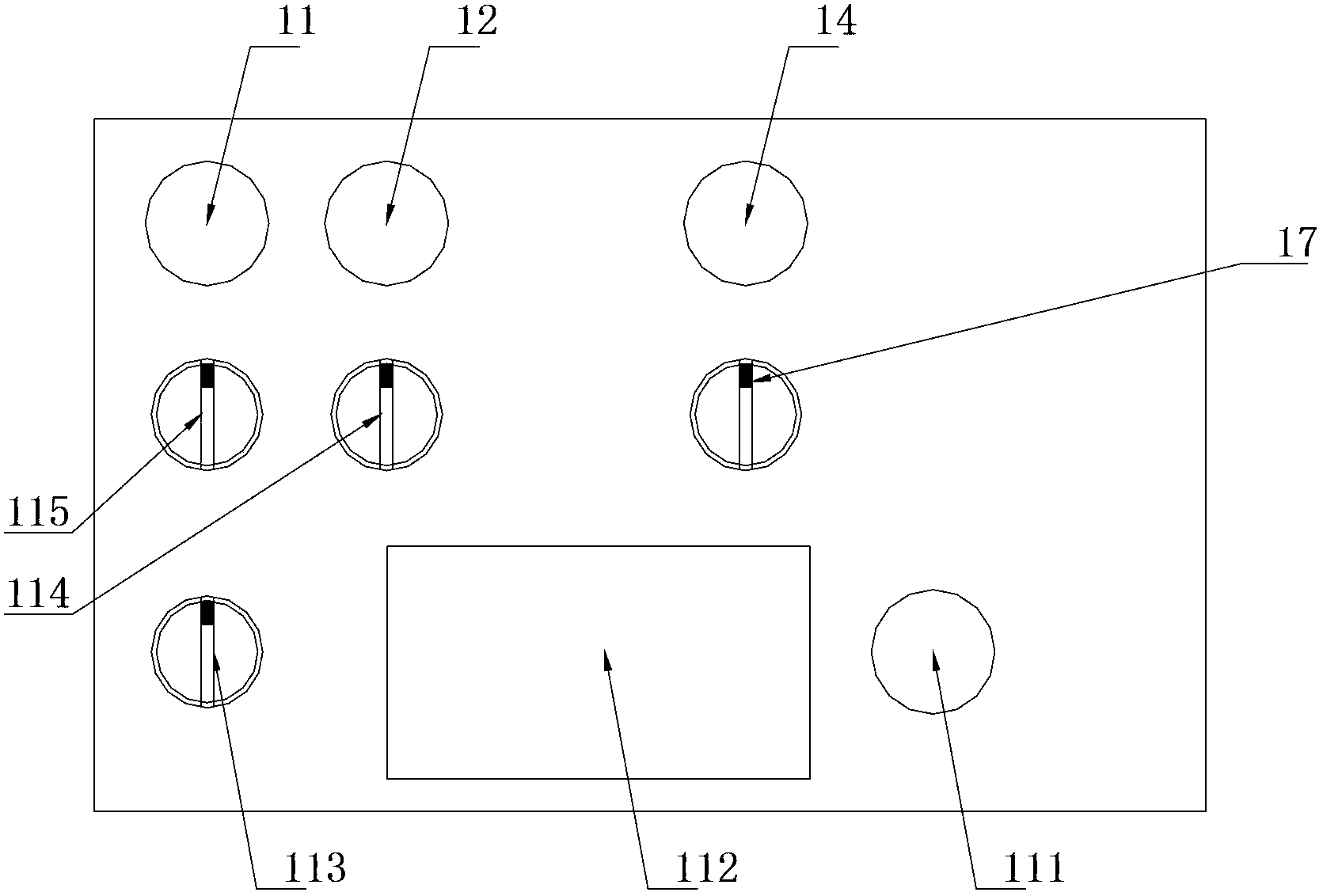

[0056] Such as Figure 5 As shown, in this embodiment, the control panel 1 for the operator to control and prompt is provided with: electric heater first gear indicator 11, electric heater second gear indicator 12, electric heater third gear indicator 13, electric heater 4th gear indicator light 14, circulating pump indicator 15, standby circulating pump indicator 16, electric heater 4th gear switch 17, circulating pump switch 18, standby circulating pump switch 19, circulating pump mode switch 110, water shortage alarm indicator Light 111, temperature display board 112, electric heater mode switch 113, elec...

Embodiment 3

[0060] Such as Image 6 As shown, in this embodiment, a heating system of a coal-fired boiler for vehicles includes: a boiler for heating water 2, a heating tube 21 with adjustable heating gear, and a radiator 3 for radiating heat in the cabin 4 The heating pipe 21 is arranged in the boiler 2, and the radiator 3 and the boiler 2 are connected by a circulating pipeline. The boiler 2 is also provided with a water temperature sensor 6 for detecting the water temperature in the boiler 2 and a water level sensor 7 for detecting the water level of the boiler. A temperature sensor 5 for detecting the temperature in the cabin 4 is also provided in the cabin 4. A circulating pump 8 and a standby circulating pump 9 are arranged between the boiler 2 and the radiator 3, and the circulating pump 8 and the standby circulating pump 9 are respectively connected to the boiler 2 and the radiator 3 through two circulating branches.

[0061] The heating pipe 21, the temperature sensor 5, the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com