UV glue for glass lamination processing based on modified silicone material and its application

A silicone and modified technology, which is applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of not being able to meet the needs of rapid curing, and achieve the effect of moderate hardness, good flexibility and fast curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

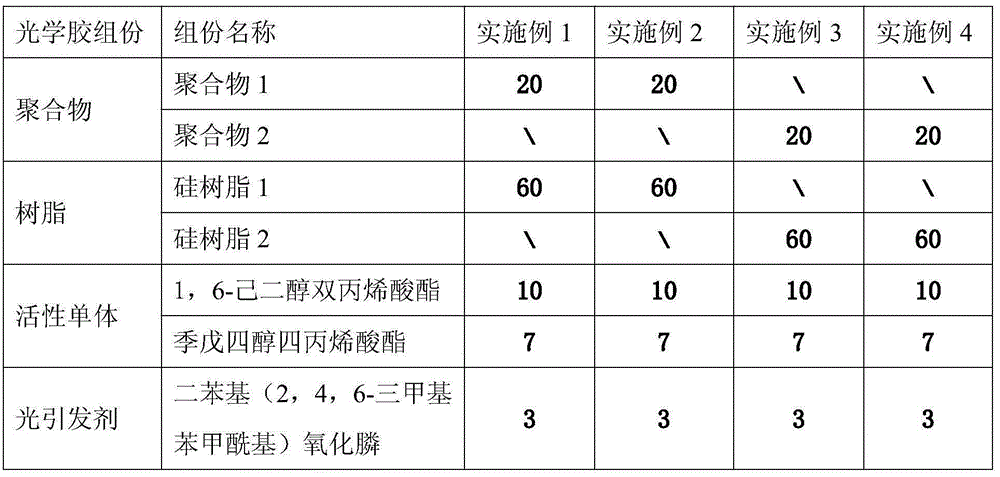

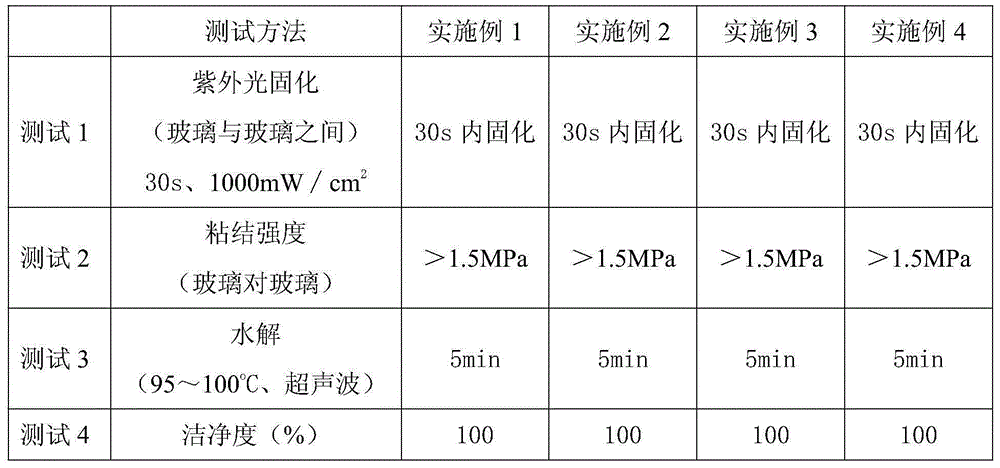

Examples

Synthetic example 1

[0024] Put allyl methacrylate and acrylic acid into the reaction kettle according to the molar ratio of 1-10, start stirring, and control the stirring speed at 20-100 rpm, and start to heat up to 60-100°C after adding the platinum catalyst. Then add hydrogen-containing silicone oil evenly and continuously within 60 minutes (the amount of hydrogen-containing silicone oil is 33% of the total mass number of allyl methacrylate and acrylic acid), maintain the reaction temperature between 60 and 100 °C, and keep warm for 0.5 ~10 hours. Then, turn off the stirring, cool to below 50°C and then open the discharge valve to discharge. The polymer co-modified by allyl methacrylate and acrylic acid group (hereinafter referred to as polymer 1) can be obtained

Synthetic example 2

[0026] Put allyl acrylate and acrylic acid into the reaction kettle according to the molar ratio of 1-10, start stirring, control the stirring speed at 20-100 rpm, add the platinum catalyst and start to heat up to 60-100°C, and then Add hydrogen-containing silicone oil evenly and continuously within 60 minutes (the amount of hydrogen-containing silicone oil is 38% of the total mass number of allyl methacrylate and acrylic acid), keep the reaction temperature between 60 and 100°C, and keep warm for 0.5-10 Hour. Then, turn off the stirring, cool to below 50°C and then open the discharge valve to discharge. The polymer co-modified by allyl acrylate and acrylic acid group (hereinafter referred to as polymer 2) can be obtained

Synthetic example 3

[0028] Put allyl methacrylate and acrylic acid into the reaction kettle according to the molar ratio of 1-10, start stirring, and control the stirring speed at 20-100 rpm, and start to heat up to 60-100°C after adding the platinum catalyst. Then add hydrogen-containing silicone resin evenly and continuously within 60 minutes (the amount of hydrogen-containing silicone resin is 60% of the total mass number of allyl methacrylate and acrylic acid), maintain the reaction temperature between 60 and 100 °C, and continuously Keep warm for 0.5-10 hours. Then, turn off the stirring, cool to below 50°C and then open the discharge valve to discharge. The silicone resin co-modified by allyl methacrylate and acrylic acid group can be obtained (hereinafter referred to as resin 1)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com